Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

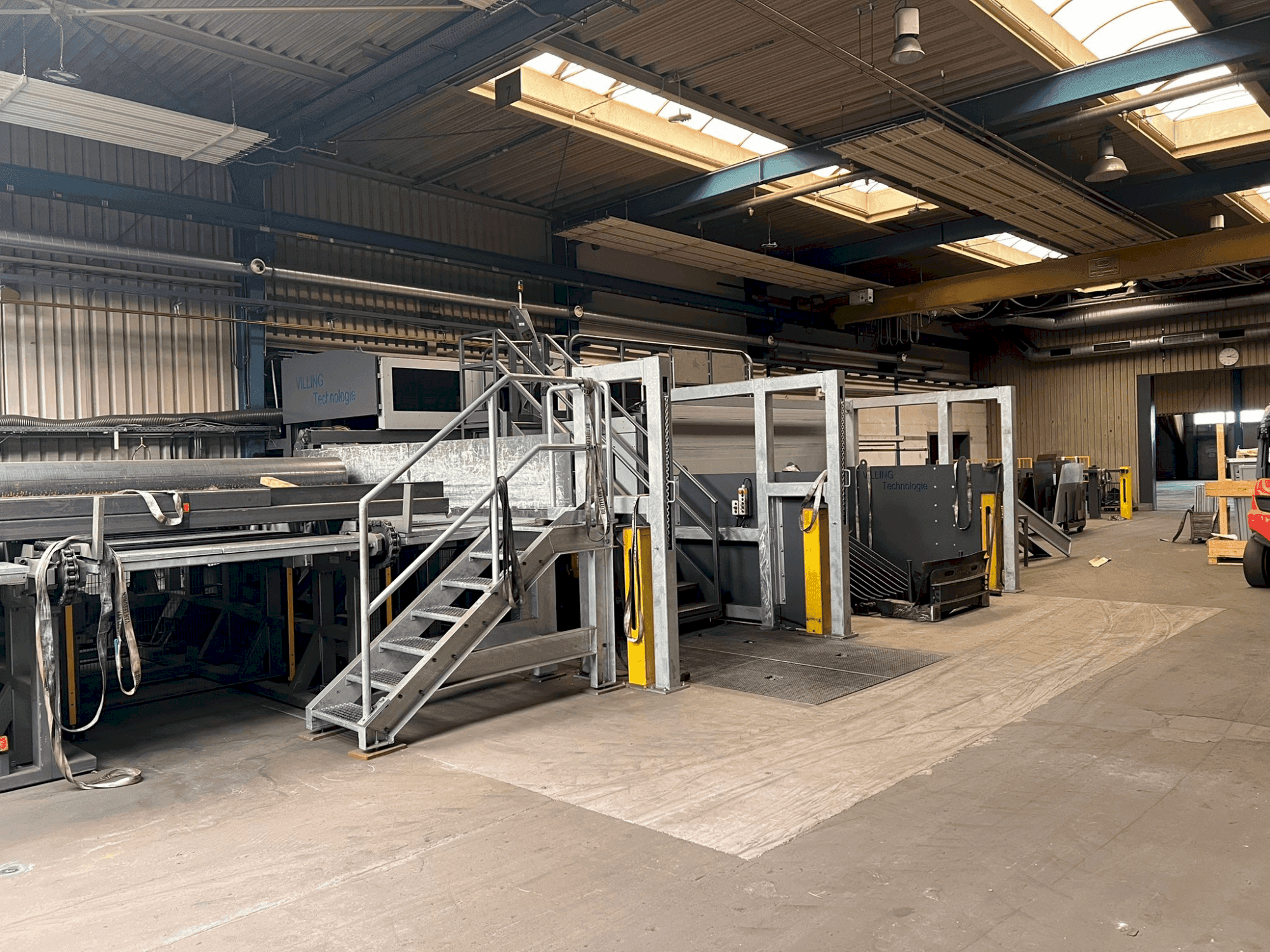

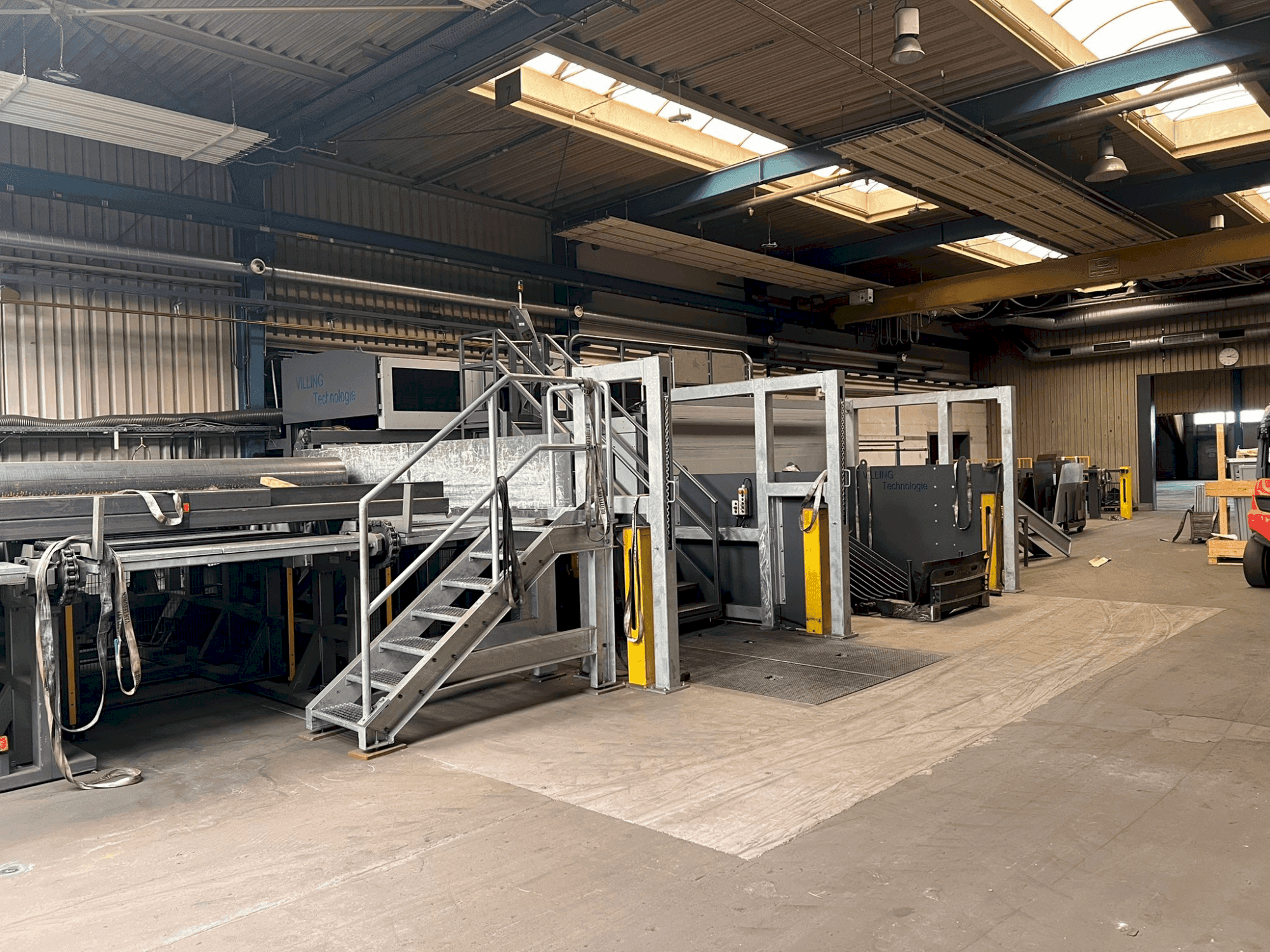

ADIGE - LT 20DE-CUT-ADI-2015-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para chapa

- ➤ Venta de ADIGE LT 20 usados | gindumac.com

Esta máquina de corte por láser de fibra ADIGE LT 20 de 5 ejes se fabricó en 2015. Cuenta con un sistema controlado por CNC de 5 ejes, capaz de manejar longitudes de tubo de 4.000 mm a 14.000 mm y cortar tubos de acero de hasta 16 mm de grosor de pared. Incluye una fuente láser de CO2 ROFIN SINAR DC 035, el software CAD y CAM 3D Artube y una estación de descarga totalmente automática. Considere la oportunidad de comprar esta máquina de corte por láser de fibra ADIGE LT 20. Contacte con nosotros para más información.

Resumen

- marca: ADIGE

- año: 2015

- MODELO: LT 20

- tipo de aplicación: Corte

- Ubicación: Alemania

- tipo de máquina: Máquina de corte láser de fibra

- Marca de unidad de control: SIEMENS

Información técnica - ADIGE LT 20

Unidad de Control

- Marca del control: SIEMENS

Recorrido

- Número de ejes: 5

- Recorrido eje X: 2000 mm

- Recorrido eje Y: 1280 mm

- Recorrido eje Z: 700 mm

Información adicional

Equipamiento adicional

- Sistema de corte por láser de tubos 3D de 5 ejes controlado por CNC

- Cabina de protección y valla de seguridad

- Estación de carga de tubos con cadena simple (cadena doble) L 14000 mm

- Disposición para pala cargadora de 18 m

- Estación prefabricada de descarga de piezas con cadena simple en versión básica L 14000 mm

- Contenedor de recogida de residuos cortados y cadena transportadora para una retirada totalmente automática

- Software Artube CAD 3D con módulos de software Artube CAD y CAM

- Extensiones y accesorios para cargadores y descargadores JUMBO

- Módulo de sonda Renishaw LP2

- Filtro de polvo fino y sistema de extracción

Beneficios de la máquina

Ventajas técnicas de la máquina

- Ajustes totalmente automáticos con opciones manuales

- Integración con la fuente láser rofin sinar dc035 sin compensador

- Instalación de unidad de refrigeración interior con circuito cerrado para fuente láser

- Espesor máximo de pared: 16 mm en corte 3d para tubos de acero

- Peso máximo: 200 kg por metro

- Longitudes de barra mecanizables: de 4000 mm a 14000 mm

- Piezas de mayor longitud de descarga: desde 3000 mm o hasta 18000 mm

- Descarga de piezas largas: 3000 - 18000 mm mediante estación de descarga frontal totalmente automática

- Longitud de descarga de piezas cortas: hasta 3000 mm a través de una estación de descarga frontal totalmente automática con pulmón de piezas acabadas.

Más información

Herramientas Potencia de la fuente láser: 3500 W Métodos de corte: 2D y 3D hasta un máximo de 45 grados Métodos de medición de tubos: Torsión, centrado, localización precisa del mecanizado de referencia mediante sonda RENISHAW y software de medición

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos