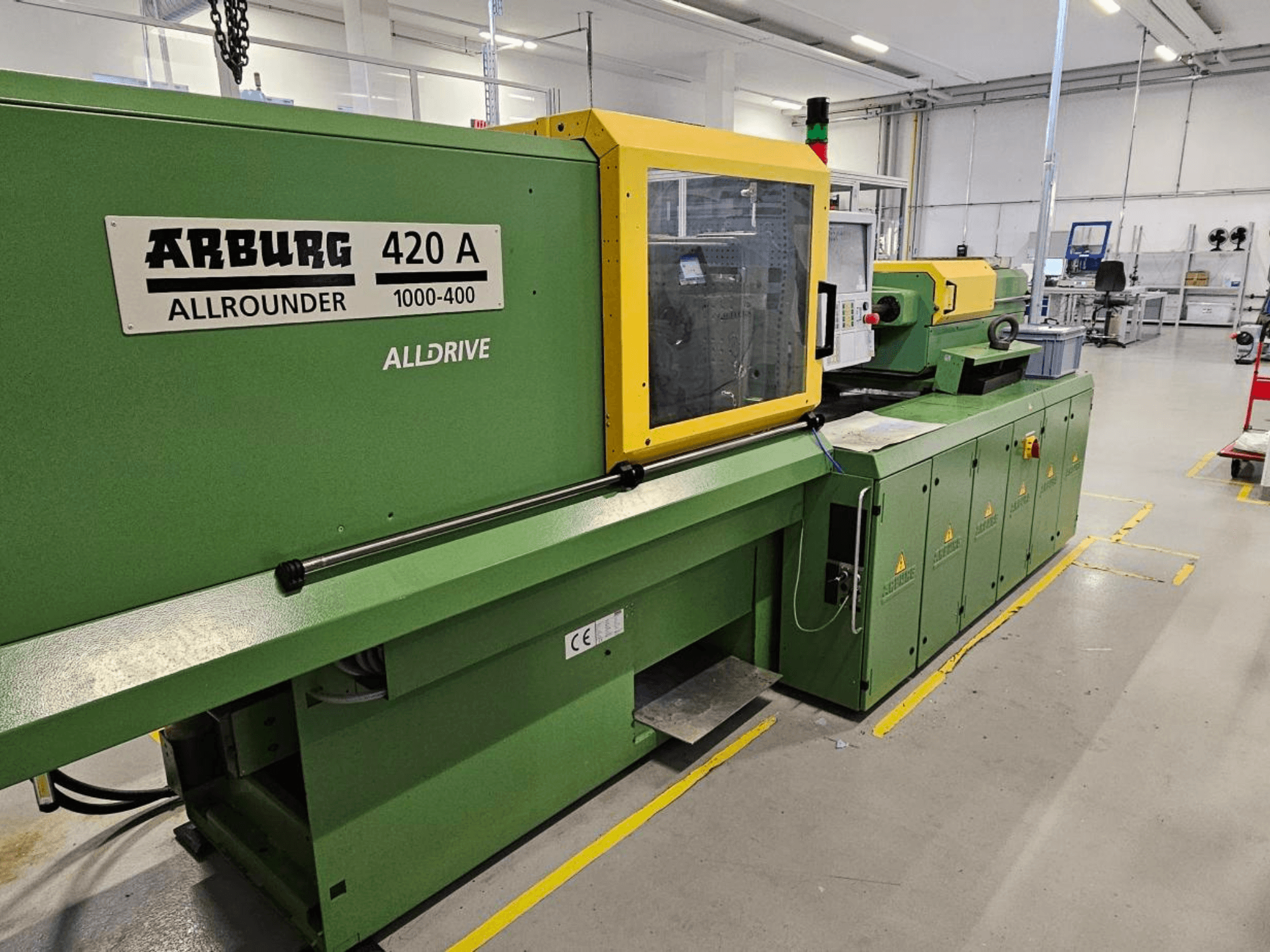

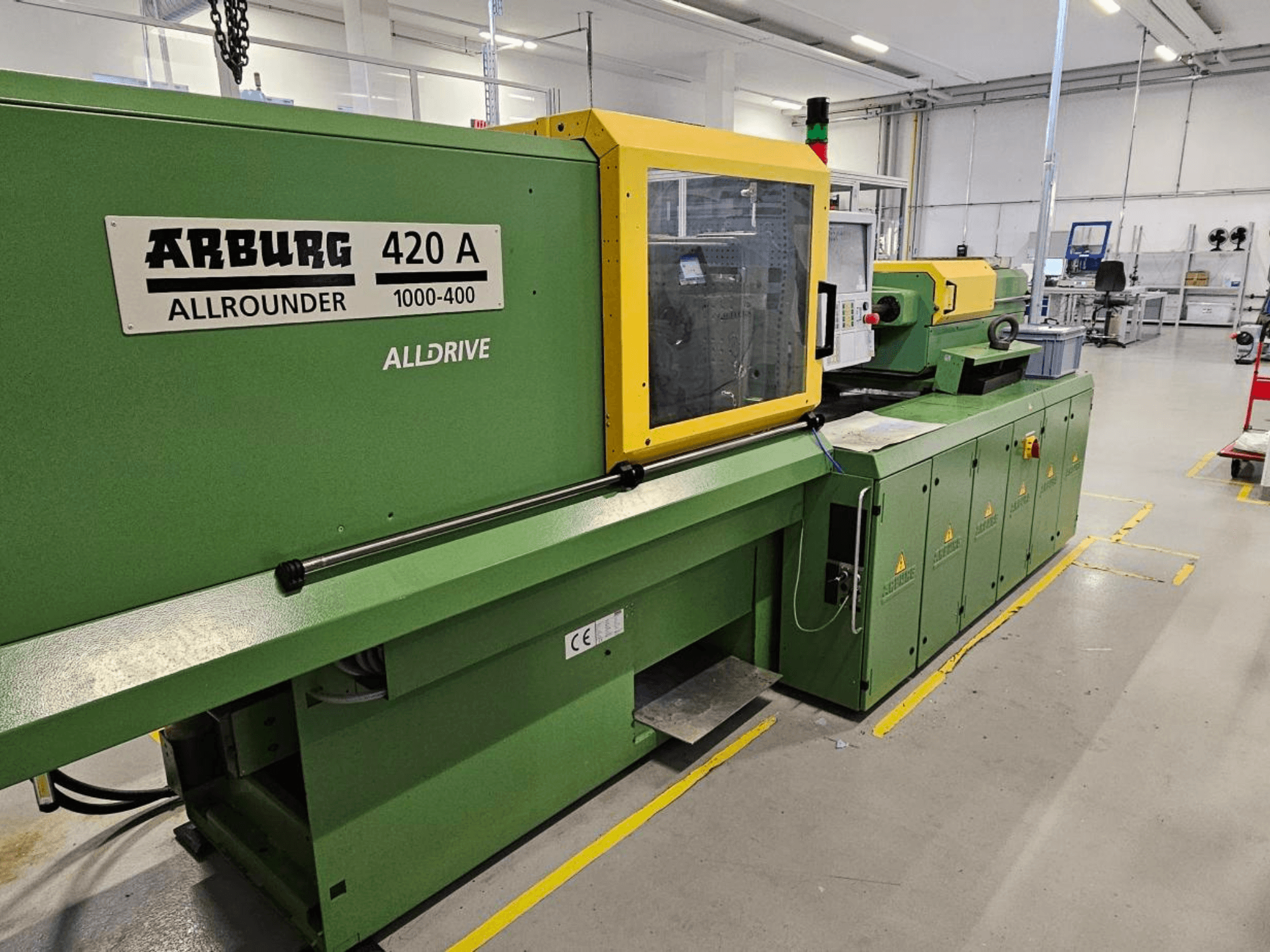

Arburg - 420A 1000-400DE-INJ-ARB-2007-00014

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Maquinaria de procesamiento de plástico

- ➤ Venta de Arburg 420A 1000-400 usados | gindumac.com

Esta Arburg 420A 1000-400 se fabricó en 2007. Cuenta con movimientos principales electromecánicos mediante servoaccionamientos, una unidad de plastificación modular con control de temperatura adaptable y un sistema de sujeción de doble palanca de cinco puntos con ajuste servoeléctrico. El sistema de control Selogica mejora la eficacia operativa. Si está buscando obtener capacidades de moldeo por inyección de alta calidad, considere la máquina Arburg 420A 1000-400 que tenemos a la venta. Contáctenos para más información sobre esta máquina.

Resumen

- marca: Arburg

- año: 2007

- MODELO: 420A 1000-400

- tipo de aplicación: Moldeo por inyección

- Ubicación: Alemania

- tipo de máquina: Máquina de moldeo por inyección hidráulica

Información adicional

Tecnología de accionamiento:

Movimientos principales electromecánicos mediante servoaccionamientos: dosificación, inyección, apertura/cierre del molde, eyector

Movimiento hidráulico para el desplazamiento de la boquilla

Procesamiento de termoplásticos

Pequeña unidad hidráulica con acumulador, 5,5 kW, bomba de 10 cm³ (Pos 132/22)

Platos de la máquina con anillo de centrado D125 mm (Pos 356/11)

Unidad de inyección (servocontrolada):

Unidad de inyección horizontal 400

Unidad de plastificación modular con acoplamiento central y control de temperatura adaptable

Conjunto de plastificación D25 mm, alta resistencia al desgaste/corrosión; boquilla abierta (220/25), punta de boquilla plana (300/00), banda calefactora (320/00) (Pos 060/25)

Temperatura de la cinta calefactora hasta 450 °C (Pos 427/02)

Acoplamiento de accionamiento estándar, doble plano (Pos 061/10)

Sin tolva (Pos 600/06)

Fuerza de contacto de la boquilla programable y servorregulada (Pos 408/03)

Unidad de sujeción:

Palanca doble de cinco puntos con ajuste servoeléctrico

Ajuste eléctrico de la altura del molde

Preparado para montar un robot lineal en el plato fijo

Protección del molde mediante control de la posición del expulsor (Pos 605/05)

Pies de máquina (Pos 605/03)

Acoplamiento rápido para barra eyectora (Pos 605/06)

Expulsor eléctrico con control de posición (Pos 381/05)

Núcleo hidráulico programable para movimientos paralelos (Pos 382/00)

Unidad de soplado de aire 1 con reductor de presión (Pos 361/01)

Circuitos de refrigeración de la máquina, regulados y programables (Pos 525/02)

Colector de agua de refrigeración con 4 circuitos regulables manualmente (Pos 512/04)

Control, armario eléctrico, interfaces:

Control Selogica

Paquetes de software (Pos 555/01-555/07): Controles de ciclo mecánico ampliados; Movimientos ampliados; Control de producción; Optimización/asistencia al operador; Control de garantía de calidad; Documentación

Armario eléctrico con regulación de temperatura (Pos 605/07)

Selogica Direct, lengua francesa (Pos 131/05)

Lector de tarjetas Flash (Pos 455/05)

Autorización del operador por tarjeta, Euromap 65 (Pos 455/06)

Alarma acústica (Pos 457/00)

Combinación de toma adicional con RCD (Pos 444/01)

12 zonas de medición de la temperatura del molde (Pos 469/12)

Banda calefactora adicional para boquilla (Pos 468/01)

Interfaz para controlador de temperatura de molde HB-Therm (Pos 453/01)

Interfaz serie USB para impresora (Pos 454/03)

Interfaz para robot Euromap 67 (Pos 425/05)

Preparación eléctrica y mecánica para robot externo (Pos 425/02)

Válvula de corte de agua (Pos 501/01)

Interfaz para secador Thermolift (Pos 464/01)

Interfaz para dosificador de color (Pos 493/00)

Equipamiento adicional

Cinta transportadora eléctrica, programable (Pos 412/02)

Trampilla de clasificación para separar las piezas buenas de las malas (Pos 375/00)

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos