Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

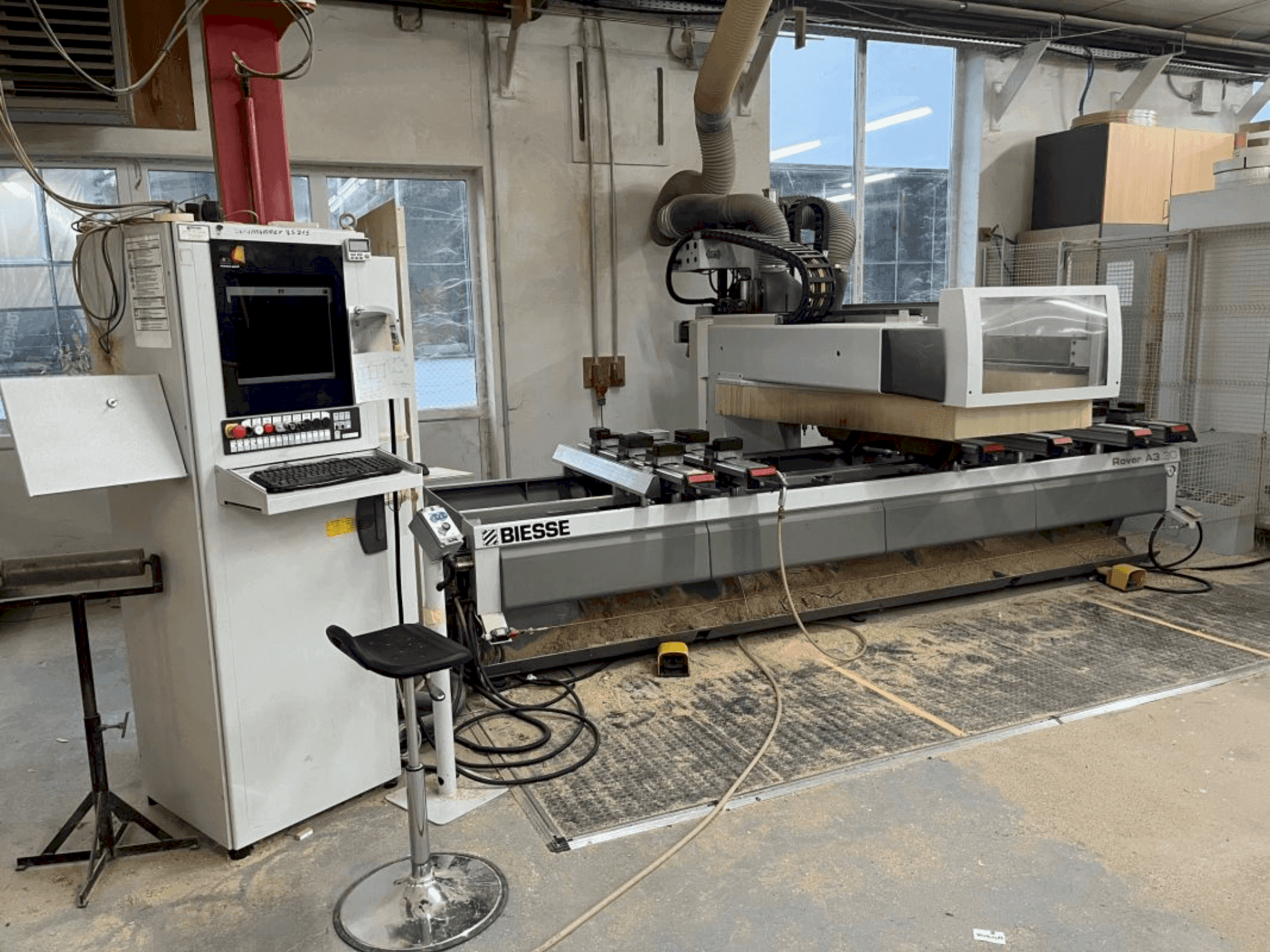

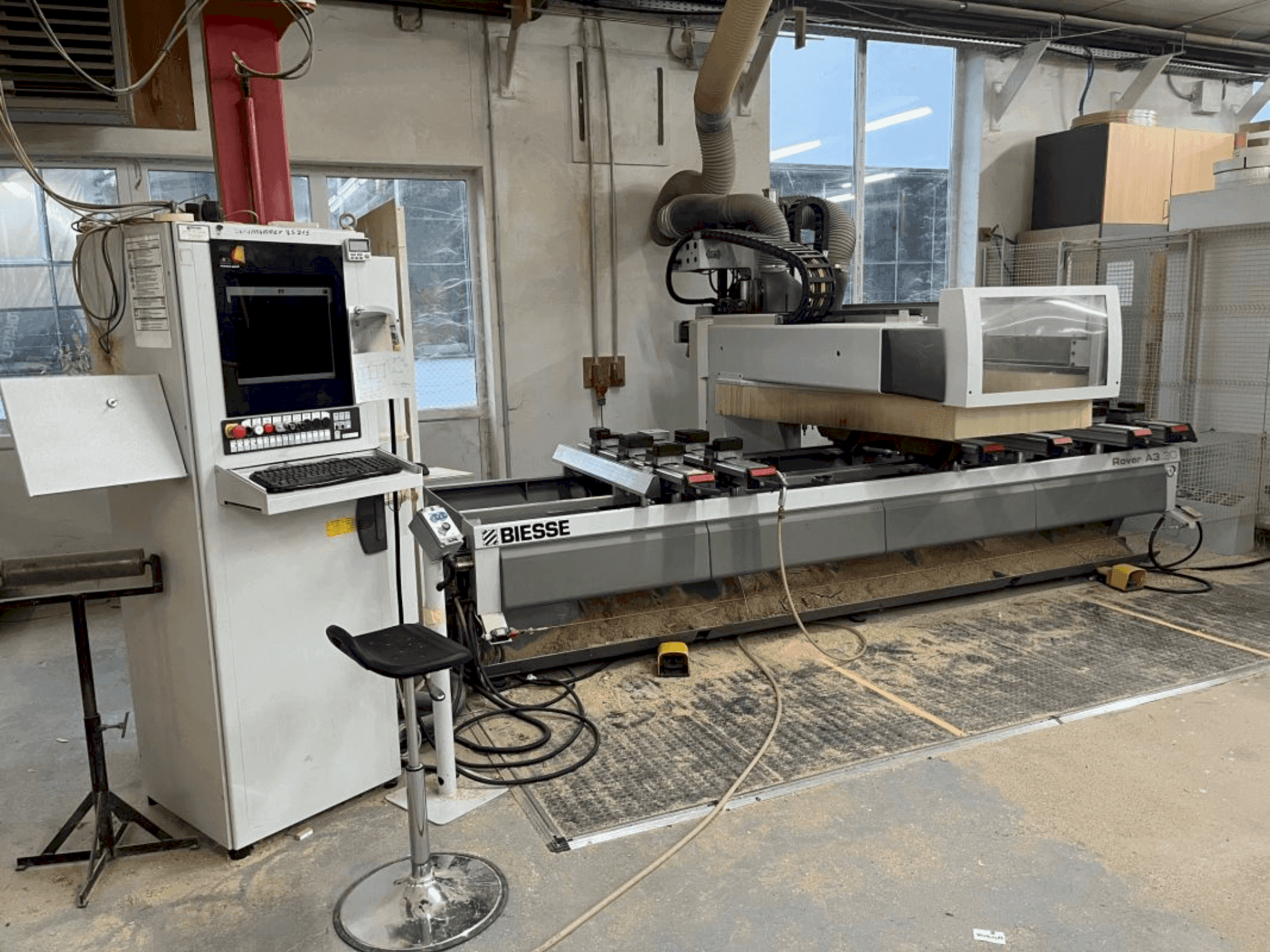

BIESSE - ROVER ADE-CNC-BIE-2007-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para madera

- ➤ Usado BIESSE ROVER A - 2007 - Venta | gindumac.com

Esta BIESSE ROVER A fue fabricada en 2007. Se trata de un centro de mecanizado de madera CNC de segunda mano que cuenta con un robusto electromandril de 7 kW, un versátil cabezal de taladrado BH 21L y un almacén de herramientas de torreta con 10 puestos. Incluye un sistema de vacío con una bomba de 90 m3/h y soporte auxiliar, que mejora la eficiencia operativa. Ideal para trabajos detallados en madera. Póngase en contacto con nosotros para obtener más información sobre esta máquina.

Resumen

- marca: BIESSE

- año: 2007

- MODELO: ROVER A

- tipo de aplicación: Mecanizado CNC

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado CNC para madera

Información técnica - BIESSE ROVER A

Recorrido

- Recorrido eje Y: 1635 mm

- Recorrido eje Z: 200 mm

Información adicional

Equipamiento adicional

- Armario de control: la máquina puede suministrarse con 380/400/414 V - 50/60 Hz

Beneficios de la máquina

Ventajas técnicas de la máquina

- Rango de trabajo: x = 3060 mm, y = 1260 mm, z = 150 mm

- Los ejes se guían por una guía lineal con rodamientos de recirculación de bolas

- Sistema de lubricación automática

Más información

Incluye convertidor para electromandrinos con una potencia máxima de 14 kW Pieza de trabajo 6 soportes de pieza ATS - L = 1200 mm 6 topes con carrera de 115 mm, bajables neumáticamente controlados por CNC, Ø 22 mm 6 topes de 115 mm de carrera posicionados a 970 mm de la parte trasera, bajables neumáticamente controlados por CNC, Ø 22 mm 4 topes laterales con carrera de 115 mm completos con equipo neumático, bajables neumáticamente controlados por CNC, Ø 22 mm 4 topes centrales desmontables con carrera de 115 mm incl. mando, bajables neumáticamente controlados por CNC, Ø 22 mm 12 mordazas para piezas estrechas Preequipamiento neumático para ayuda de posicionamiento 4 ayudas de posicionamiento (cada ayuda de posicionamiento puede soportar 36 kg) 18 módulos de vacío 132 x 146 x H48 mm (cada módulo se puede extraer y girar fácilmente en el portamódulos con una separación de 15°) Preparación para cinta transportadora de virutas integrada en la bancada de la máquina Sistema de vacío Bomba de vacío 90 m3/h a 50 Hz, 108 m3/h a 60 Hz Sistema de vacío auxiliar Herramientas Electromandril de 7 kW (9,5 CV) con adaptador ISO 30 6,6 kW (9 CV), 12000 rpm Inserto S1 7 kW (9,5 CV), 12000 rpm Inserto S6 Velocidades de rotación de 1000 - 24000 rpm programables NC Cabezal de taladrado BH 21L equipado con 21 herramientas independientes Sierra ranuradora en dirección X, diámetro 120 mm (profundidad de corte máx. 25 mm) Almacén de herramientas de torreta con 10 puestos Ø máx. Ø a plena carga (10 herramientas) 120 mm Peso total máx.: 40 kg

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos