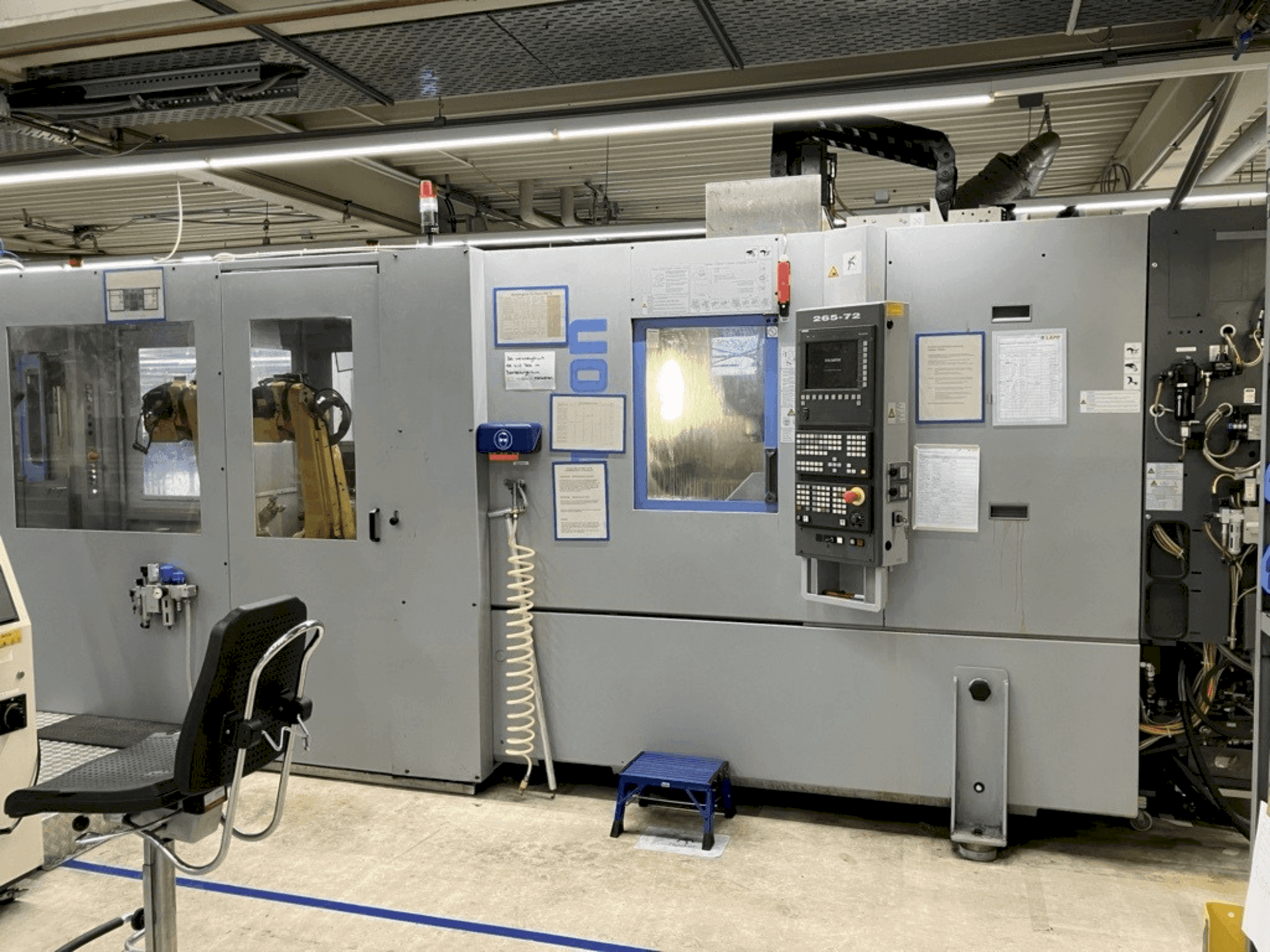

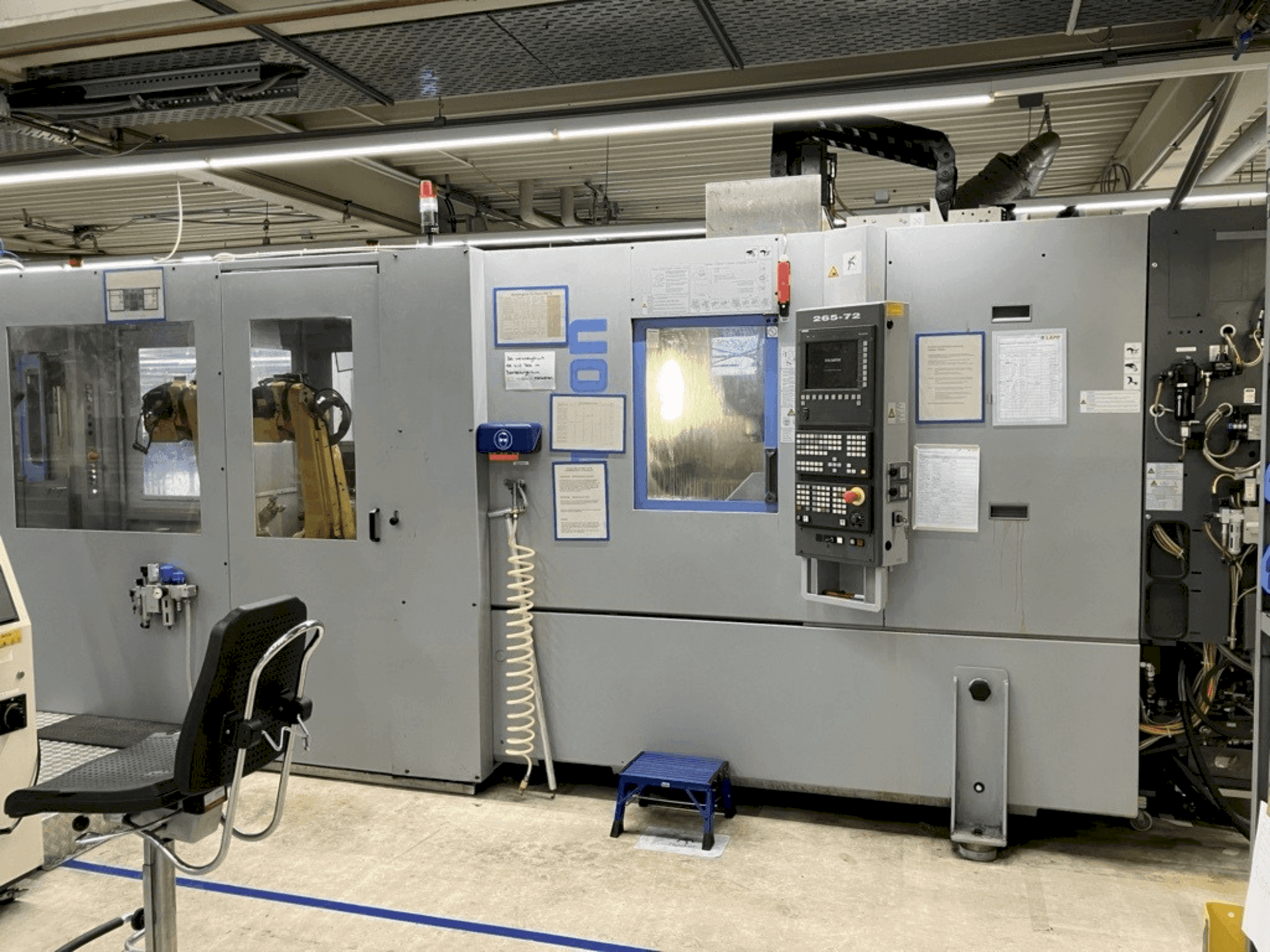

CHIRON - FZ 12 KWDE-MIL-CHI-2012-00002

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Venta de CHIRON FZ 12 KW usados | gindumac.com

Este centro de mecanizado vertical CHIRON FZ 12 KW de 3 ejes se fabricó en 2012. Cuenta con un husillo de alta velocidad con una velocidad máxima de 12 000 rpm y una velocidad de desplazamiento rápido de hasta 60 m/min en el eje Z. La máquina incluye un cambiador automático de herramientas de 24 ranuras y puede soportar una carga de mesa de hasta 500 kg. Ideal para tareas de mecanizado de precisión. Póngase en contacto con nosotros para obtener más información sobre esta máquina.

Resumen

- marca: CHIRON

- año: 2012

- MODELO: FZ 12 KW

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado vertical

Información técnica - CHIRON FZ 12 KW

Dimensiones

- Carga de mesa: 500 kg

Recorrido

- Número de ejes: 3

- Recorrido eje X: 550 mm

- Recorrido eje Y: 320 mm

- Recorrido eje Z: 360 mm

Especificación Técnica

- Max. Tool Weight: 5 kg

- Velocidad del husillo: 12000 RPM

Información adicional

Beneficios de la máquina

Ventajas técnicas de la máquina

- Ejes controlados: 6 ejes

- Alcance: 704 mm

- Aceleración/desaceleración: 0 a 12000 min-1 en 0. 6 segundos

- Superficie de sujeción: 820 x 440 mm²

- Capacidad de perforación en st 60: Ø 16 mm

- Roscado: m 16

- Capacidad de fresado en st 60: 80 cm³/min

- Aceleración: ejes x e y 0,7 g, eje z 1,0 g

Más información

Movimiento Alcance y velocidad de movimiento de los ejes J1: 340°/360° (opción) a 350°/s J2: 200° a 350°/s J3: 388° a 400°/s J4: 380° a 450°/s J5: 240° a 450°/s J6: 720° a 720°/s Momento de carga admisible: J4 y J5: 11,9 Nm J6: 6,7 Nm Repetibilidad: +/- 0,02 mm Velocidad máxima J1: 195°/s J2: 175°/s J3: 180°/s J4 y J5: 400°/s J6: 600°/s Momento de carga admisible J4 y J5: 7,7 Nm J6: 9,8 Nm Herramientas Cambiador automático de herramientas: Portaherramientas: 24 Tiempo de cambio de herramienta: aprox. 0,9 s Tiempo de viruta a viruta: aprox. 2,4 s Las piezas se suministran a través de un sistema de alimentación automatizado y se cargan secuencialmente en los centros de mecanizado Chiron mediante dos robots industriales Fanuc. Una vez finalizados los procesos de mecanizado, se retiran de nuevo. A continuación, los robots transfieren los componentes a un sistema de transferencia, que los transporta al sistema de limpieza posterior. La línea de lavado integrada garantiza una limpieza fiable de los componentes de acuerdo con las especificaciones de limpieza definidas. Tras el proceso de lavado, dos robots Fanuc de funcionamiento sincronizado se hacen cargo de las piezas limpias en la sección posterior del sistema. En función de las especificaciones del proceso, las piezas se paletizan automáticamente o se procesan en una fase posterior, por ejemplo, mediante remachado. Todo el sistema funciona de forma totalmente automática.

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos