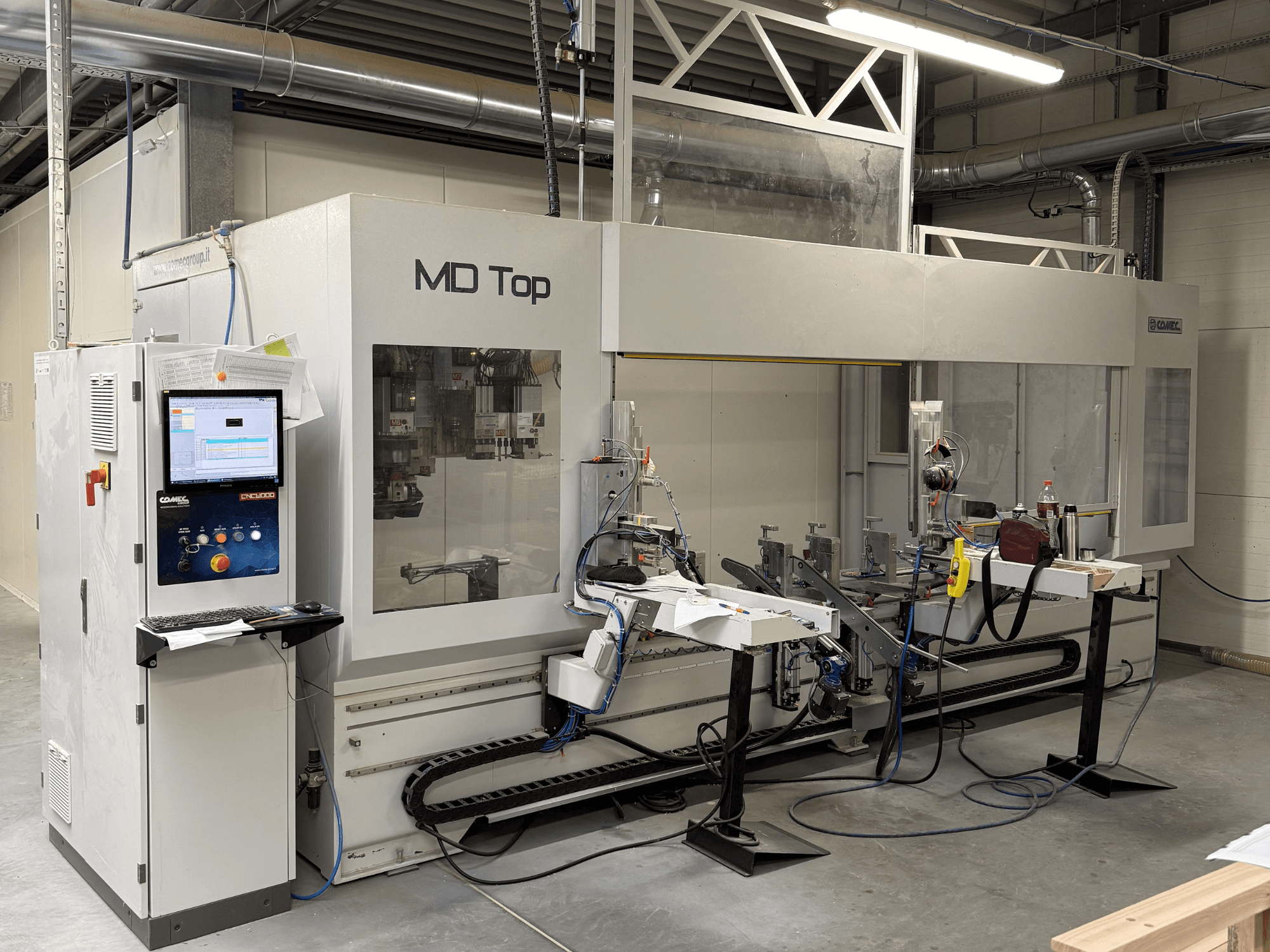

COMEC - MD TOP XLPL-CNC-COM-2020-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para madera

- ➤ Usados COMEC MD TOP XL - 2020 - Venta | gindumac.com

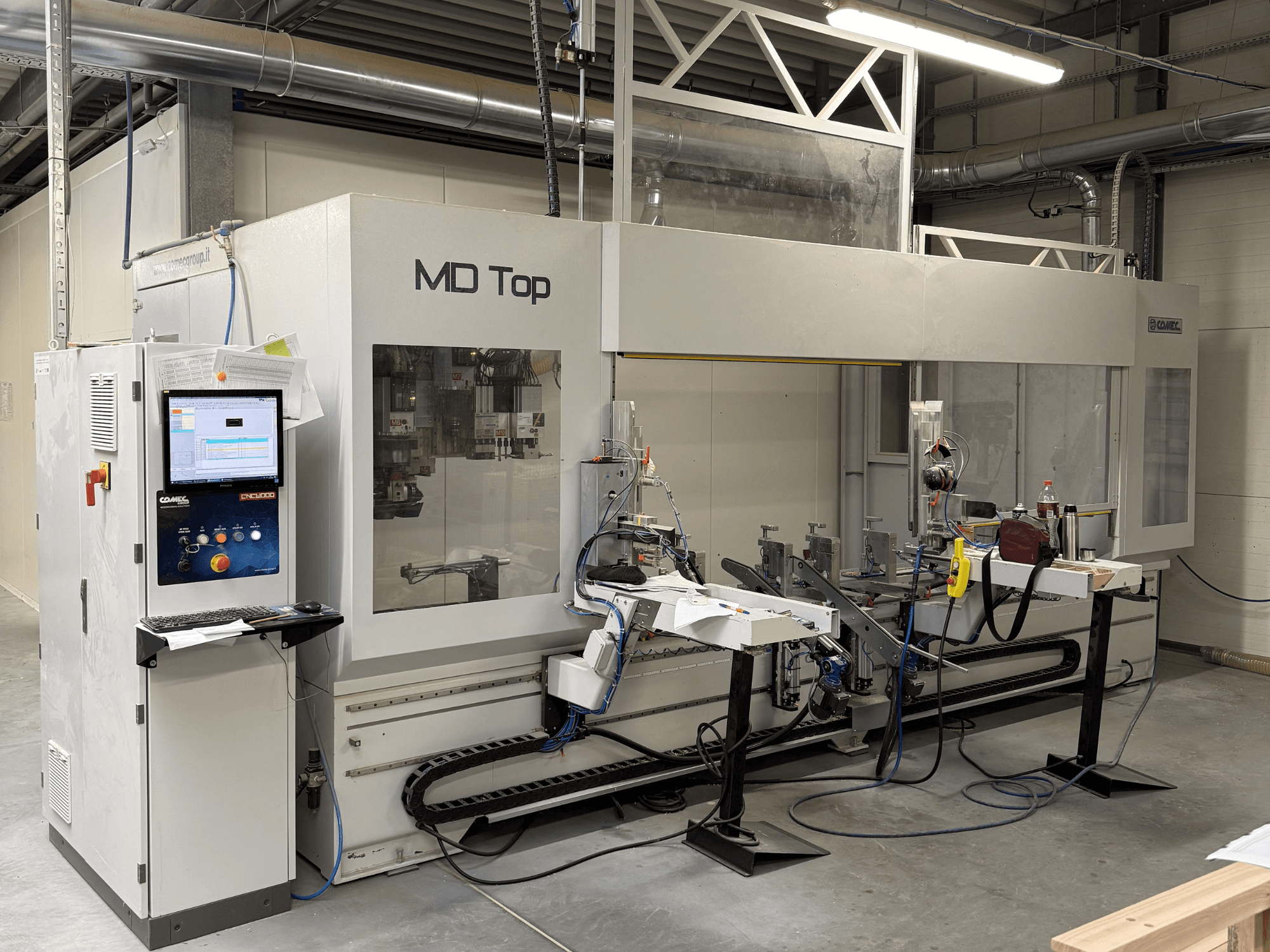

Este centro de mecanizado de madera CNC de 3 ejes COMEC MD TOP XL se fabricó en 2020. Cuenta con una robusta estructura monobloque, ejes de alta velocidad de posicionamiento de hasta 70 m/min y versátiles electromandriles para taladrado, fresado y corte. La máquina incluye una unidad de control CAD-CAM con pantalla táctil de 17" y cerramientos de seguridad completos. Si está buscando una máquina de alta calidad para trabajar la madera, considere la máquina COMEC MD TOP XL que tenemos a la venta. Contacte con nosotros para más información.

Resumen

- marca: COMEC

- año: 2020

- MODELO: MD TOP XL

- tipo de aplicación: Mecanizado CNC

- Ubicación: Polonia

- tipo de máquina: Centro de mecanizado CNC para madera

Información técnica - COMEC MD TOP XL

Recorrido

- Número de ejes: 3

- Recorrido eje X: 3350 mm

- Recorrido eje Y: 200 mm

- Recorrido eje Z: 180 mm

Especificación Técnica

- Potencia del husillo: 5.6 kW

- Velocidad del husillo: 18000 RPM

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos