Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

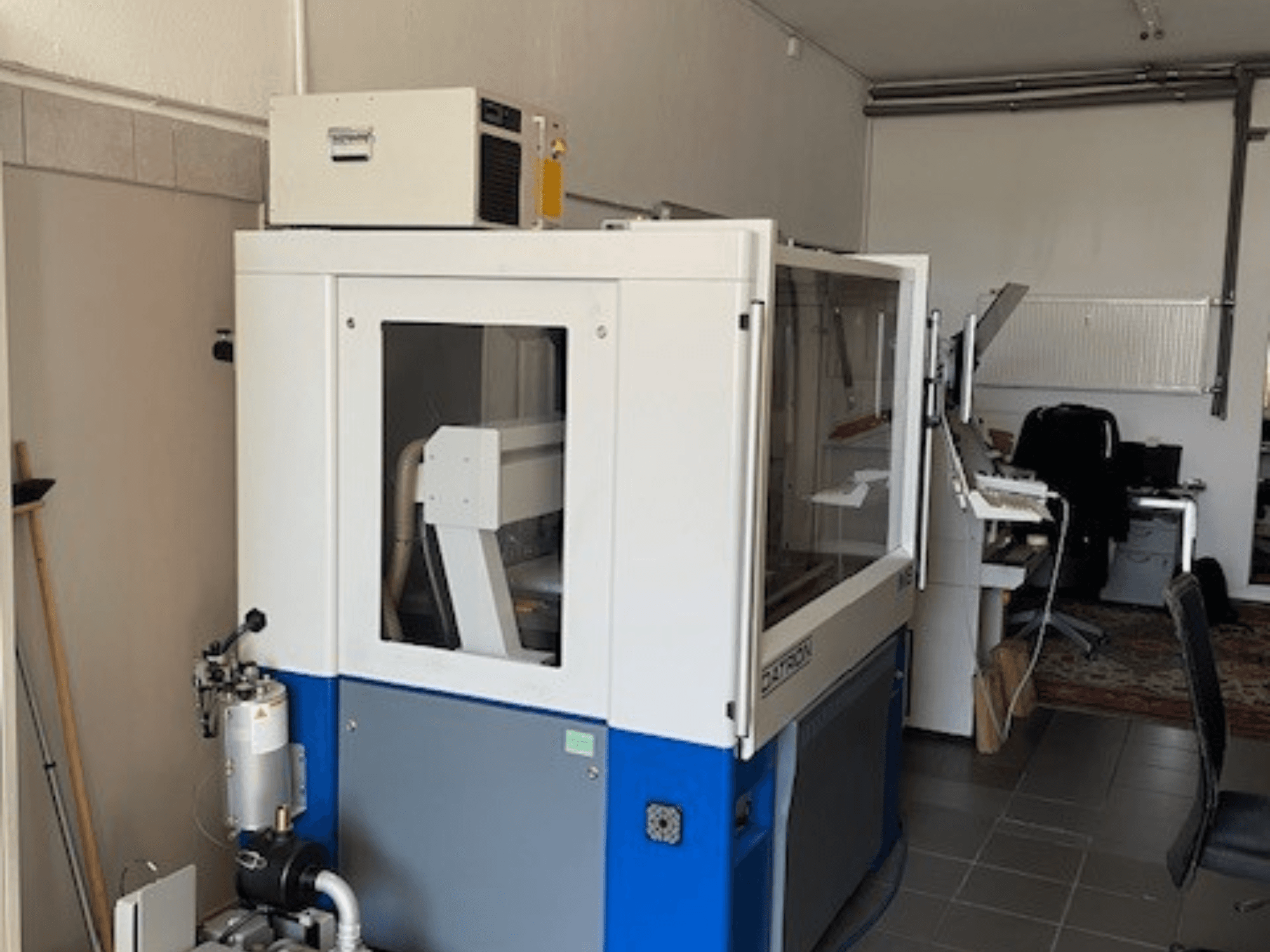

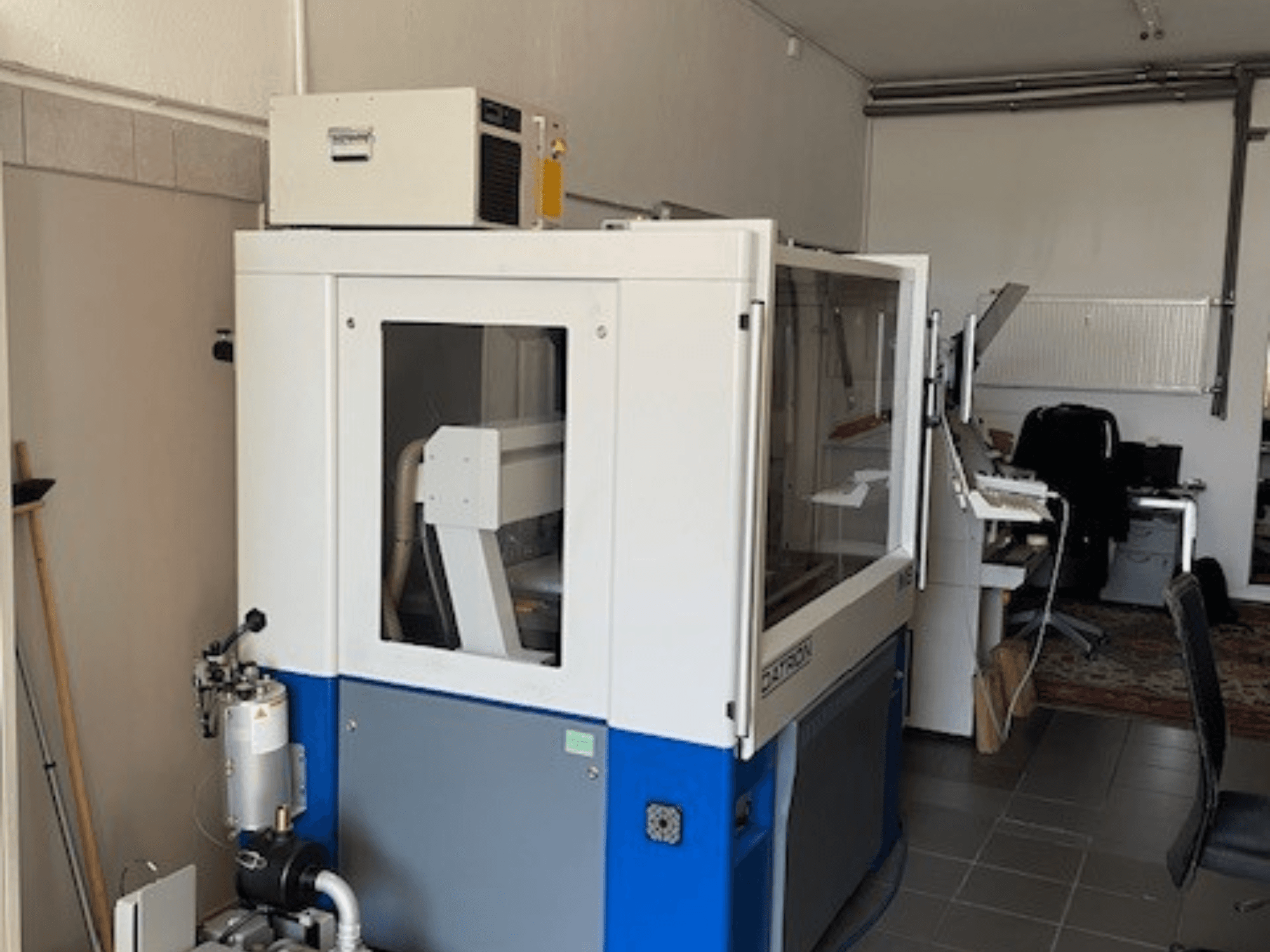

Datron - M8DE-MIL-DAT-2011-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Se vende centro de mecanizado Datron M8 usado | gindumac.com

Este centro de mecanizado vertical Datron M8 de 3 ejes se fabricó en 2011. Presenta un robusto diseño de pórtico con accionamientos de doble soporte y guías de precisión. Las especificaciones clave incluyen un husillo SF de 2,0 kW con velocidades de hasta 60.000 rpm, un cambiador de herramientas de 15 posiciones y un rango de recorrido de 1020 mm x 800 mm x 240 mm. Ideal para tareas de mecanizado detalladas y precisas. Póngase en contacto con nosotros para obtener más información sobre esta máquina.

Resumen

- marca: Datron

- año: 2011

- MODELO: M8

- horas de producción: 50

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado vertical

Información técnica - Datron M8

Dimensiones

- Altura de la máquina: 1950 mm

- Longitud de la máquina: 1850 mm

- Peso de la máquina: 915 kg

Recorrido

- Número de ejes: 3

- Recorrido eje X: 1020 mm

- Recorrido eje Y: 800 mm

- Recorrido eje Z: 240 mm

Información adicional

Configuración: Husillo SF 2,0 kW HighS H2.0 (hasta 60.000 rpm), conmutación directa

Sujeción de la herramienta: Sujeción directa, Ø máx. 8 mm; pinza de 6 mm

Cambiador de herramientas: 15 posiciones con sensor de longitud, sujeción directa

Diseño de la máquina: Diseño de pórtico con accionamientos de doble apoyo; hormigón polímero macizo sobre bastidor de acero; guías de precisión

Mesa: Mesa de coordenadas (sin recorte)

Recorridos: X 1020 mm, Y 800 mm, Z 240 mm; distancia entre pórticos 200 mm

Accionamientos: Servoaccionamientos digitales; husillo de bolas por eje

Velocidad de avance: hasta 20 m/min

Mando: Control DATRON 3D-CNC V9; ordenador LCD/control con teclado y monitor de 19" (unidad de CD integrada)

Refrigeración/lubricación: Sistema de refrigeración por pulverización DATRON; refrigerador de husillo tipo H-K GK; opción de velocidad para husillo SF

Equipamiento adicional

Palpadores/sensores:

Sensor XYZ (completo con brazo giratorio, materiales de funcionamiento, montaje), característica: control total por software

Sensor TP-D del eje Z

Sensor de altura del eje Z

Técnica de sujeción:

Placa de sujeción del módulo de vacío 650 x 450 x 40 mm, 3 conexiones (aprox. 27 kg); accesorios: VakuCard, VakuCardMatt

Placa de sujeción del módulo de ranura en T 460 x 250 x 83 mm (250 x 460 x 80 nominal), con mordaza fija, 2 filas, 450 tipo B; incluye casquillo de centrado y junta; accesorios: elementos de sujeción de carrera corta

Elemento de sujeción de carrera corta, neumático-hidráulico, tipo KSE-PH (130 x 110 x 65 mm, 1,6 kg; presión de servicio 1-8 bar; carrera 7 mm; fuerza de sujeción hasta 3.200 N); incluye manguera de aire comprimido; accesorio: mordaza fija

Sistema de vacío:

Distribuidor de vacío de 3 vías V V-3 con válvulas de cierre (incl. cierre adicional con ventilación), vacuómetro, racor pasamuros, mangueras y herrajes de montaje completos

Bomba de vacío tipo VP-B-1, rotativa de paletas, lubricación por cárter de aceite; capacidad de aspiración 100 m³/h; presión final 20 mbar; motor 3,0 kW; 3 x 400 V; nivel de presión sonora 67 dB(A); dimensiones 748 x 433 x 310 mm; peso 70 kg; capacidad de aceite 2 l; incluye contactor trifásico, válvula rotativa, presostato diferencial, depósito de vacío, interruptor de protección del motor, control de aceite, filtro de aspiración y contactor trifásico

Capacidad de superficie de sujeción de hasta 1.000 x 1.500 mm

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos