Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

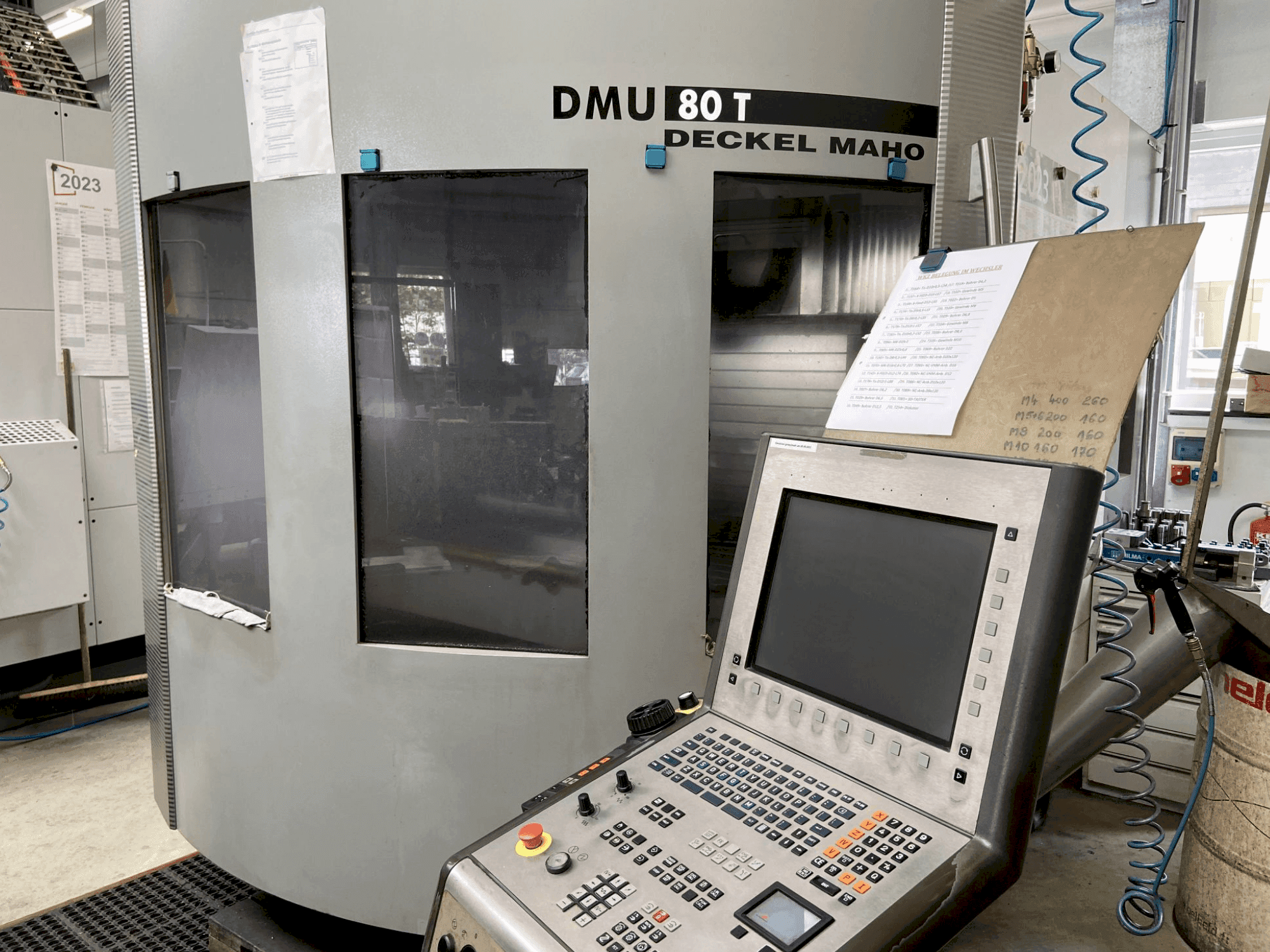

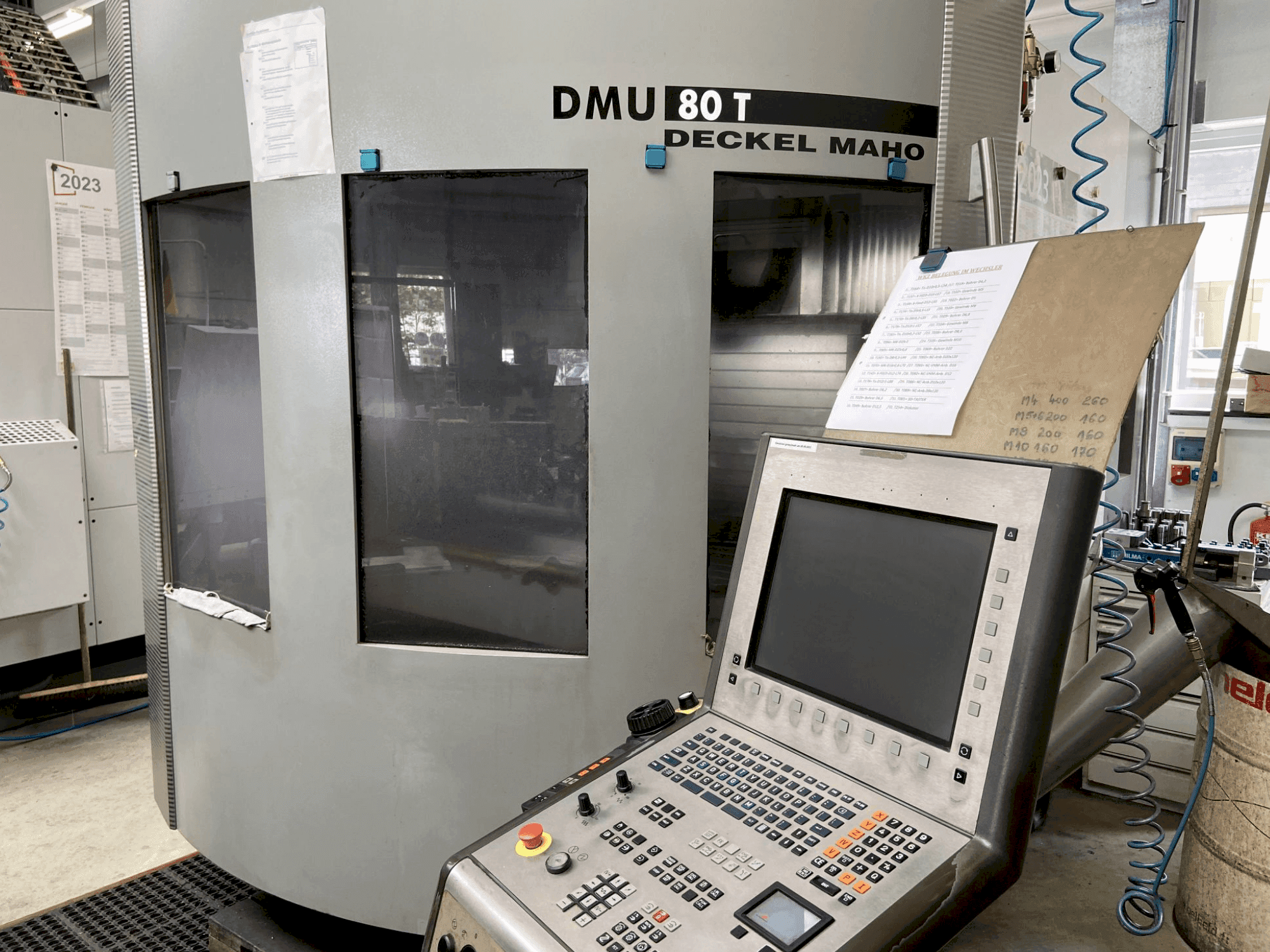

DECKEL MAHO - DMU 80 TDE-MIL-DEC-2002-00005

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- DECKEL MAHO DMU 80 T (2002) Universal Machining Center

This DECKEL MAHO DMU 80 T (2002) Universal Machining Center was manufactured in 2002 in Germany. It is equipped with 3+2 axis (B-axis and NC dividing head), a 12,000 rpm spindle and a 32 tool magazine. The machine runs with tool taper SK 40 and is controlled by a Heidenhain control unit with iTNC 530 model. Electronic handwheel , spiral conveyor and 3D path control are available. It is still in operation, and has always been in single-shift production. The machine works accurately, even if Y-axis has some play, which can result in a slightly wavy surface structure during fine finishing. Fits/stitch dimensions can be achieved in the +/- 0.015 range. The tool changer flap falls when the machine is at a standstill for a longer period of time (cylinder fastening worn out). Overall machine is in good, reliable working condition and can be inspected anytime. The spindle was replaced in September 2017 and has approx. 5700 hours. See photo and video gallery for detailed impressions - or original delivery note (German) attached for all technical positions.

Resumen

- marca: DECKEL MAHO

- año: 2002

- MODELO: DMU 80 T

- horas de producción: 25602

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado universal

- Marca de unidad de control: HEIDENHAIN

Información técnica - DECKEL MAHO DMU 80 T

Unidad de Control

- Marca del control: HEIDENHAIN

- Modelo del control: iTNC 530

Recorrido

- Número de ejes: 5

- Recorrido eje X: 880 mm

- Recorrido eje Y: 630 mm

- Recorrido eje Z: 630 mm

Especificación Técnica

- Potencia del husillo: 10 kW

- Velocidad del husillo: 12000 RPM

- Tamaño del cono: SK 40

Información adicional

Additional equipment

- Electronic handwheel

Machine Benefits

Qualitative Machine Benefits

- The machine has always been in single-shift operation and is currently still in operation

- The b-axis and the nc dividing head are particularly noteworthy

- The spindle was replaced in september 2017 and has approx. 5700 hours

- Machine on hours: 53046 // cutting hours: 25602 // new spindle hours (since end of 2017): 5700

Technical Machine Benefits

- 5-axis (3+2) machining center

- Nc swivel milling head (b-axis)

- 32-positions tool magazine // tool changing device pick-up system

- Tool clamping to din 69872

- Spiral conveyor

- 3d path control

- Tailstock manual, tip height 160 mm

Extra Information

The tool changer flap falls when the machine is at a standstill for a longer period of time (cylinder fastening worn out) // Y-axis has some play, which can result in a slightly wavy surface structure during fine finishing. Otherwise the machine works accurately // Fits/stitch dimensions can be achieved in the +/- 0.015 range // Approx. 200x SK40 tool and collet holders including collets available (upon extra charge)

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos