Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

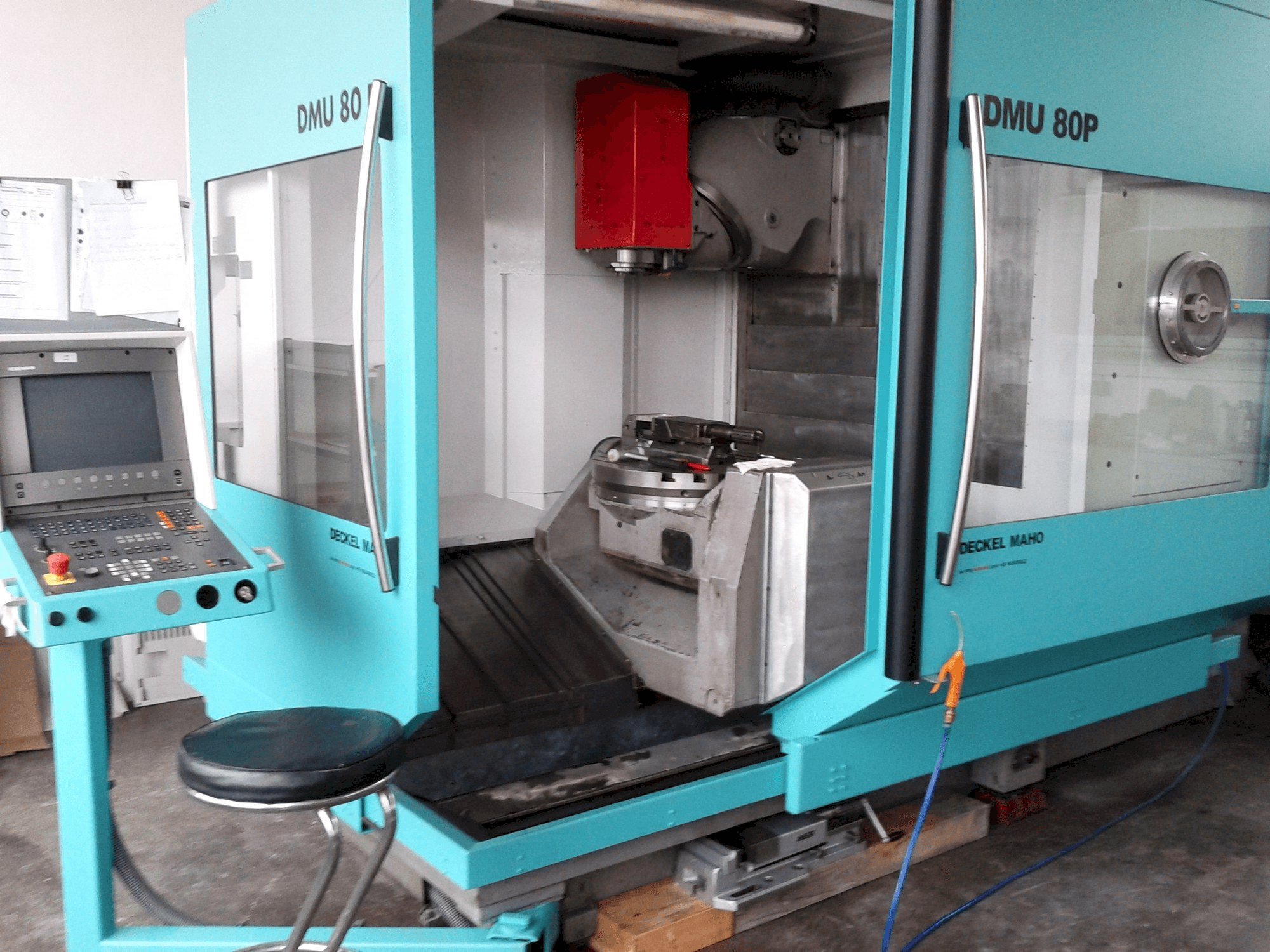

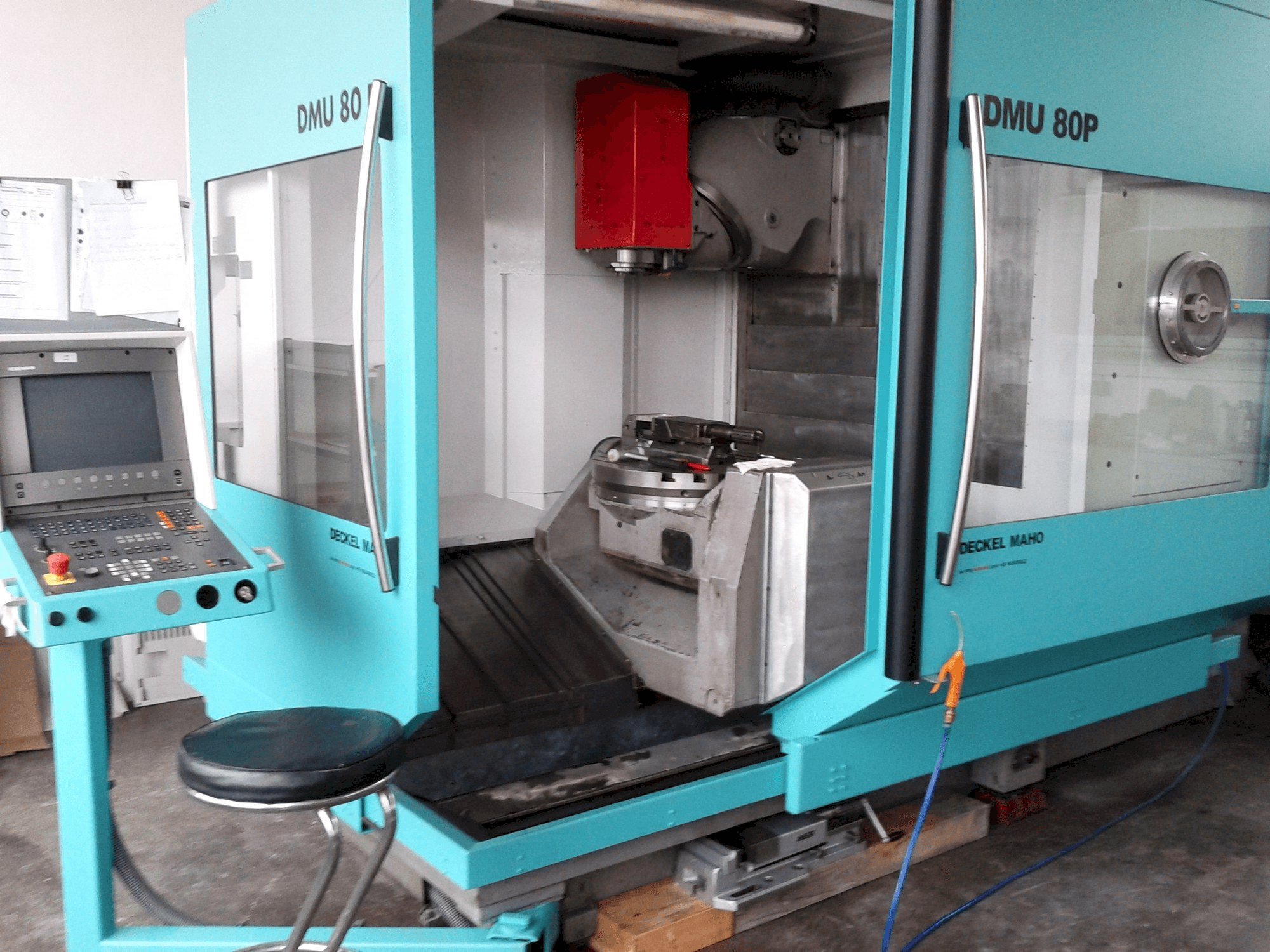

DECKEL MAHO - DMU 80PDE-MIL-DEC-1999-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- DECKEL MAHO DMU 80P Universal Machining Center

This DECKEL MAHO DMU 80P Universal Machining Center was built in the year 1999 and has been working for 56145 hours, from which 27389 are spindle hours. This machine is in a very good condition and can be tested under power. Its table, as well as the tool clamps, were overhauled and got a Heidenhain LE426PB swap computer with a fast SSD hard disk. The Siemens Simodrive LT-Module Interface 108A Type: 6SN1123-1AA00-0LA1 has been exchanged. Also, the spindle encoder has been exchanged. The zero position must be adjusted once a day. The side window has a crack but this does not affect functionality. Many tool holders are converted to IK. Aluminium cover strips has been renewed on the side. Inside and outside include a new spindle cover, and new inscriptions received. New switch on button green. The control panel has got handles. Valve hoses partly renewed. Hydraulic pump sound insulated. New LED tube light.

Resumen

- marca: DECKEL MAHO

- año: 1999

- MODELO: DMU 80P

- horas de producción: 27389

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado universal

- Marca de unidad de control: HEIDENHAIN

Información técnica - DECKEL MAHO DMU 80P

Unidad de Control

- Marca del control: HEIDENHAIN

- Modelo del control: TNC430

Recorrido

- Eje A máximo: 45°

- Eje C: 360°

- Recorrido eje X: 800 mm

- Recorrido eje Y: 700 mm

- Recorrido eje Z: 600 mm

Especificación Técnica

- Peso máximo de herramienta: 630 kg

- Velocidad del husillo: 8000 RPM

- Refrigeración a través del husillo: Sí

Información adicional

Additional equipment

- 50 tool holders

- Tools

Machine Benefits

Qualitative Machine Benefits

- Air pressure controller with filter

- New led tube light

- Hydraulic pump sound insulated

- Valve hoses partly renewed

- New switch on button green. The control panel has got handles

- Inside and outside incl. Spindle cover new painted and new inscriptions received

- Aluminium cover strips has been renewed on the side

- Many tool holders converted to ik

Technical Machine Benefits

- Electronic handwheel

- 5 water jets and 5 air jets

- Spindle with internal cooling and tool magazine 30x

- Tlc software version: gr472. 01r

- Nc software version: 280476-29

- Coolant tank 600 litres

- Coolant pressure 20-40 bars

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos