Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

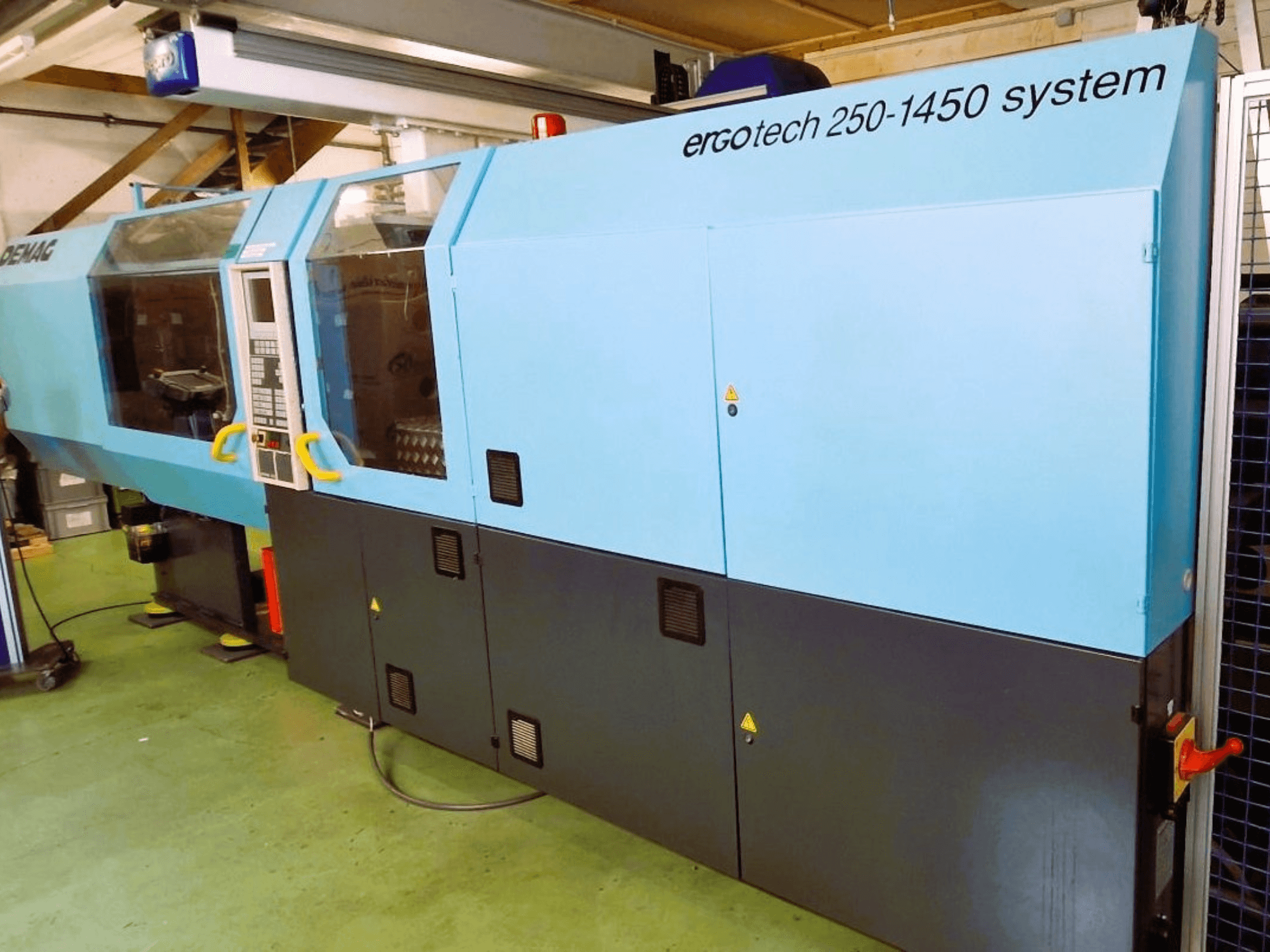

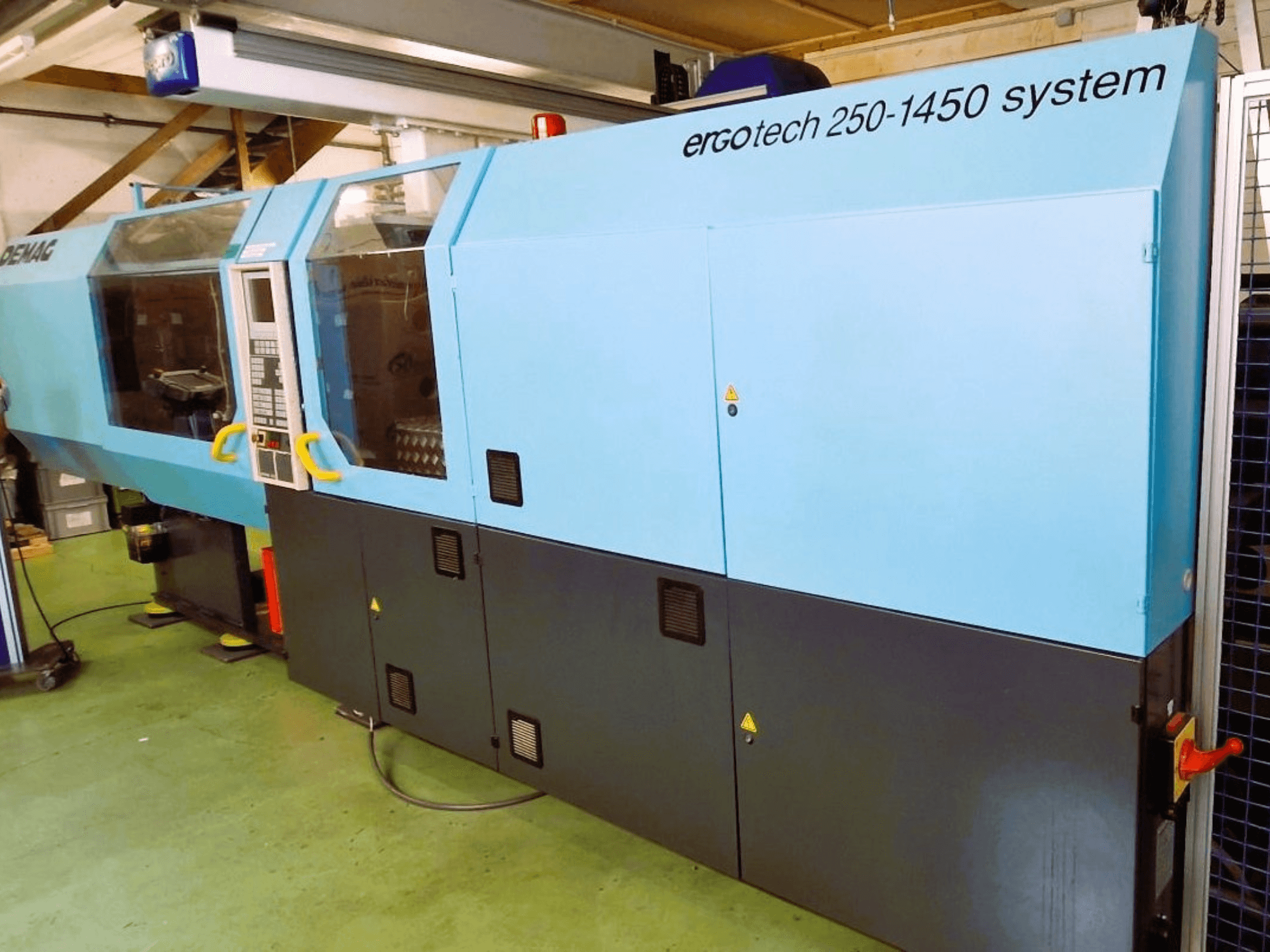

DEMAG - Ergotech System 250 - 1450CH-INJ-DEM-1995-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Maquinaria de procesamiento de plástico

- ➤ Se vende DEMAG Ergotech System 250 - 1450 de segunda mano

Este sistema DEMAG Ergotech 250 - 1450 se fabricó en 1995. Se trata de una robusta máquina de moldeo por inyección hidráulica con una fuerza de cierre de 2500 kN y un diámetro de husillo de 70 mm. Está equipada con un robot Sepro, una bomba de control hidráulico DFE de bajo consumo y un diseño modular para aplicaciones versátiles. Las dimensiones de la máquina son 6,4 × 1,9 × 2,3 m, e incluye un completo terminal de operador con una pantalla LCD de 10 pulgadas. Póngase en contacto con nosotros para obtener más información sobre esta máquina.

Resumen

- marca: DEMAG

- año: 1995

- MODELO: Ergotech System 250 - 1450

- tipo de aplicación: Moldeo por inyección

- Ubicación: Suiza

- tipo de máquina: Máquina de moldeo por inyección hidráulica

Información técnica - DEMAG Ergotech System 250 - 1450

Dimensiones

- Altura de la máquina: 2300 mm

- Longitud de la máquina: 6400 mm

- Peso de la máquina: 13500 kg

Información adicional

Unidad de sujeción:

Fuerza de sujeción: 2500 kN (fuerza de sujeción 2750 kN)

Carrera de apertura máx.: 675 mm

Altura herramienta/molde: 330-710 mm

Distancia libre entre columnas 630 × 630 mm

Distancia máx. entre placas de sujeción de herramientas 950 × 950 mm

Peso máx. del molde: 3300 kg

Carrera del expulsor: 200 mm

Fuerza de expulsión: 80 kN (fuerza de retracción 35 kN)

Palanca basculante doble de 5 puntos, compacta; palancas basculantes lubricadas con aceite con impulsos optimizados

Soporte para plato móvil; placas de montaje del molde ajustables en altura

Tirantes endurecidos por inducción (cuádruples), columnas superiores extensibles

3 velocidades de apertura/cierre del molde; fuerza de cierre ajustable en IBED

Expulsor hidráulico del molde; sistema de medición de la posición de las placas del molde

Desconexión automática de la refrigeración del molde en caso de avería

Unidad de inyección

Unidad de inyección 1450

Diámetros de husillo: 50 / 60 / 70 mm (actualmente equipado: 70 mm)

Relación L/D: 20:1 (todos los cilindros de tornillo)

Carrera de dosificación máx.: 270 mm

Sistema de retracción activa del husillo; retracción hidráulica del husillo tras mantener la presión o plastificar

Zonas del cilindro calentadas por separado; 5 bucles de control de temperatura autooptimizables (cilindro y boquilla)

Control de velocidad mediante 10 puntos de apoyo (perfil poligonal)

Regulación de la velocidad del husillo mediante 6 etapas

Regulación de la presión de mantenimiento: 10 etapas (perfil poligonal)

Inyección mediante sistema de medición de desplazamiento (rápido/lento)

Contrapresión ajustable; control del cojín durante la presión de retención

2 Sistema de moldeo por inyección de 3 velocidades; velocidad de expulsión de dos etapas

Boquilla

Carrera de la boquilla máx.: 440 mm

Profundidad de inmersión de la boquilla: 40 mm

Fuerza de contacto de la boquilla: 110 kN

Rendimiento/datos:

Peso máx. de la pieza (PS): 927 g

Capacidad de la tolva de llenado: 110 L

Capacidad del depósito de aceite: 700 L

Unidad de bombeo: 37 / 45 kW

Conexión eléctrica 380 V / 50 Hz

Controles y HMI:

Máquina de moldeo por inyección totalmente controlada; diseño modular

Bomba de control hidráulico DFE de bajo consumo

Sistema de cambio de cilindros con conversión automática de datos

Función de rampa incorporada para apertura/cierre del molde

Terminal de operador IBED con LCD de 10" y unidad de disquete de 3,5

Entrada de consigna en bar, cm³, mm/s o %.

Soporte gráfico para perfiles de inyección

Adquisición de datos de proceso PDE (20 parámetros + 100 gráficos de ciclo); control de proceso

Diagnóstico de errores en texto plano

Transferencia de datos de proceso a otras máquinas ERGOtech

Programa de encendido/apagado con pulverización de expulsión

Función de ayuda con disquete

Interfaces y conexiones:

EOAT/bus de periféricos para conexión de dispositivos

Interfaz V24 para impresora de copia impresa; programa de impresora + copia impresa

Interfaz de manejo VDMA 24465 (32 polos)

Interfaz de protección de herramientas (bloqueo de la placa de expulsión)

Conexión de herramientas DIN estándar

Combinación de enchufes

2× 220 V / 2× 380 V + desconexión automática

2× 220 V + 1× 380 V toma (SO)

Válvulas neumáticas (3/2) para placa de montaje de herramientas

Control del agua de refrigeración: 8 vías (ampliable a 12 vías)

Indicador visual de averías (luz intermitente)

Acabado de pintura:

Parte inferior antracita; parte superior azul/verde/gris claro

Equipamiento adicional

Robot Sepro (manipulación)

Recorrido horizontal X: total 3000 mm (X1 = 2580 mm / X2 = 420 mm)

Accionamiento: servomotor

Velocidad máx. de desplazamiento: 4000 mm/s

Lado de salida: parte trasera de la máquina

Altura base fija aprox.: 480 mm

Tolva de material

Controlador de temperatura con registro gráfico

Unidad de control del agua de refrigeración 8 vías, ampliable a 12 vías

Fijación resistente de la máquina (pies antivibración)

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos