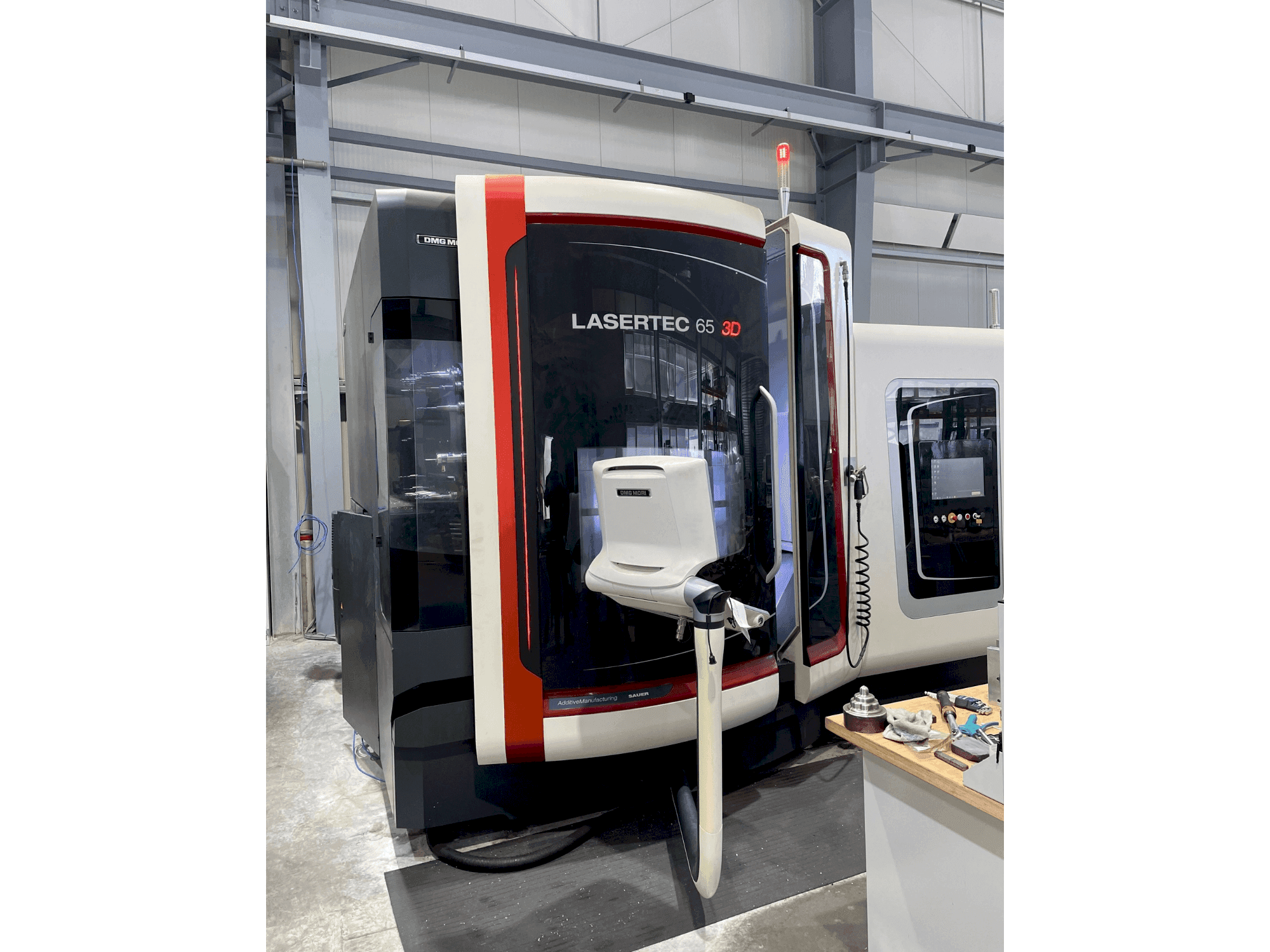

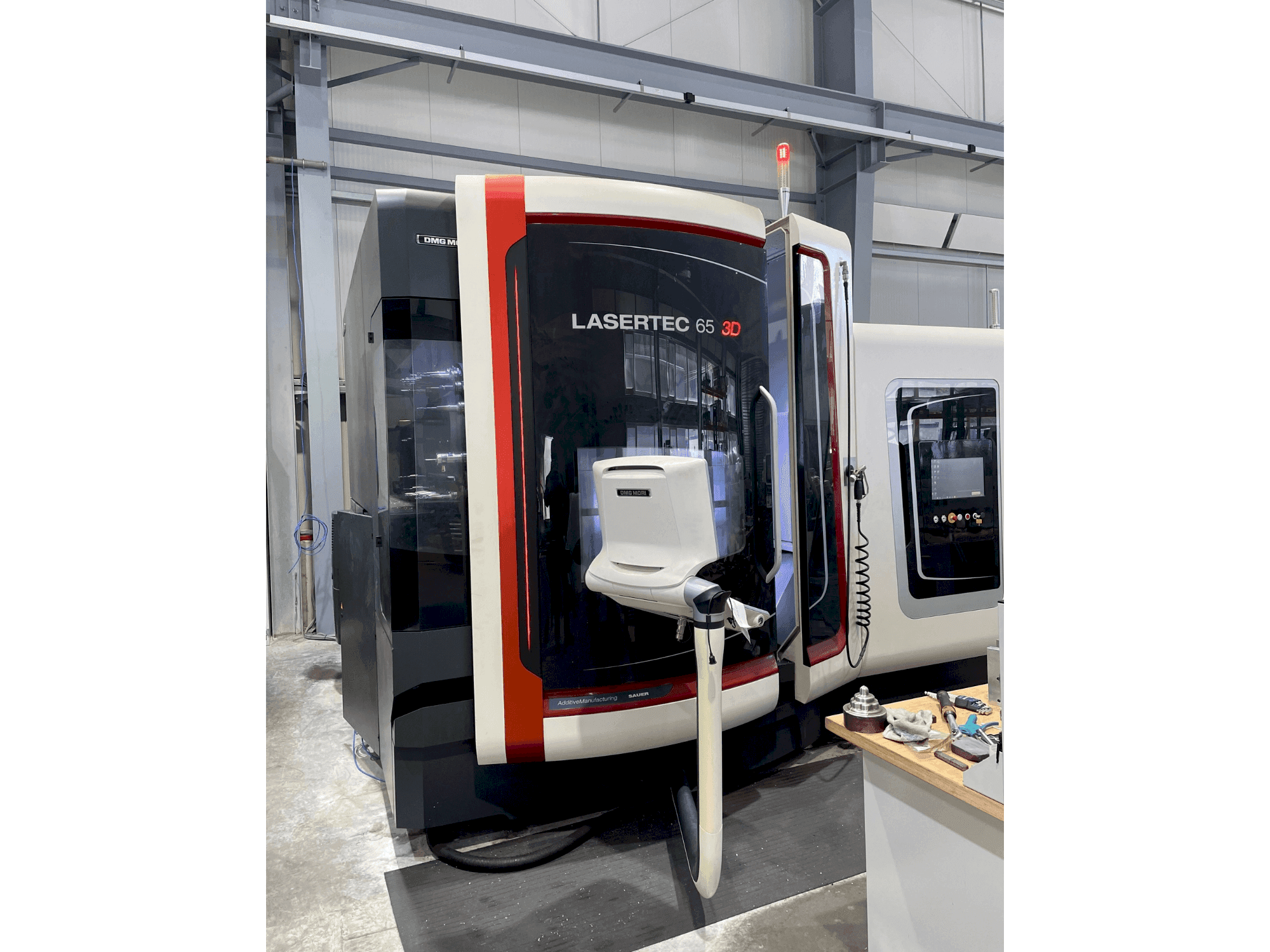

DMG MORI - LASERTEC 65 3D HybridAT-MIL-DMG-2014-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- DMG MORI LASERTEC 65 3D Máquina híbrida de precisión de 5 ejes para fresado y mecanizado láser

Esta máquina de precisión DMG MORI LASERTEC 65 3D Hybrid de 5 ejes para fresado y mecanizado láser fue fabricada en el año 2014 en Alemania. Es especial por la capacidad de producir componentes mediante Impresión 3D y post-procesarlos al mismo tiempo. Ideal para fabricantes que necesitan una solución de fabricación aditiva de alto rendimiento de componentes metálicos en 3D. La máquina cuenta con una integración fija del cabezal láser en el cabezal para un mayor espacio de instalación y más rendimiento. Además, ofrece aplicación de material en 5 ejes mediante boquilla coaxial para una distribución uniforme del polvo independientemente de la dirección de acumulación del láser. Es la solución dedicada ideal para prototipos, series pequeñas, reparación y revestimiento. Esta LASERTEC 65 3D está equipada con un husillo motorizado SK 40 integrado con una velocidad de husillo de hasta 14.000 1/min. Además, funciona con un láser de diodo guiado por fibra de 2,5 kW de potencia láser. Además del suministro interno de refrigerante (IKZ), viene con sonda de medición Renishaw y opción de medición de herramientas Blum. Además, es apreciada por su área de trabajo de generosas dimensiones y fácil acceso, junto con unas dimensiones de desplazamiento de 650 × 650 × 560 mm (X / Y / Z). Se trata de una máquina de 5 ejes sumamente adaptable, adecuada para una amplia gama de tareas de fresado y láser, que ofrece resultados de alta calidad sin concesiones.

Resumen

- marca: DMG MORI

- año: 2014

- MODELO: LASERTEC 65 3D Hybrid

- horas de producción: 1520

- tipo de aplicación: Fresado

- Ubicación: Austria

- tipo de máquina: Centro de mecanizado universal

Información técnica - DMG MORI LASERTEC 65 3D Hybrid

Dimensiones

- Profundidad de la máquina: 1050 mm

- Altura de la máquina: 2000 mm

- Largo de mesa: 800 mm

- Ancho de mesa: 650 mm

Recorrido

- Número de ejes: 5

- Recorrido eje X: 650 mm

- Recorrido eje Y: 650 mm

- Recorrido eje Z: 560 mm

Especificación Técnica

- Número de herramientas: 60

- Potencia del husillo: 14 kW

- Velocidad del husillo: 14000 RPM

- Refrigeración a través del husillo: Sí

Información adicional

Equipamiento adicional

- Sistema de refrigeración interior 40 bar, 23 l/min

- Transportador de virutas de cinta rascadora con sistema de refrigeración de 600 litros, filtro de cinta de papel

- Sonda de medición por infrarrojos Renishaw OMP 60 Versión para SK 40 (la sonda se introduce automáticamente en el husillo de trabajo desde el almacén de herramientas)

- Pistola de enjuague con bomba 2 bar/40 l/min

- Separador de neblina de aceite/emulsión

- Medición de herramientas en el área de trabajo de Blum Laser

- MPC Control de protección de máquinas y 3D quickSET

- Recargo por alimentador de polvo Twin System

- Unidad de aspiración con filtro secundario

- volante electrónico Siemens 840D

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Inserción y extracción automatizadas del cabezal de procesamiento láser para aplicación o fresado láser de diodo guiado por fibra con 2. 500 vatios de potencia

- Óptica de procesamiento con lente de enfoque

- Unidad de refrigeración que sopla aire por el centro del husillo

- Gran área de trabajo para piezas de hasta ø 500 mm, 350 mm de altura y máx. 600 kg

- Accesibilidad y ergonomía: gran apertura de puerta, carga de piezas por delante y accesibilidad total

- Ocupa poco espacio con 12 m2 de superficie de instalación

- Paquete de seguridad para fallos de alimentación

- La máquina fue actualizada al estado de máquina nueva por dmg en 2020 y luego entregada.

Ventajas técnicas de la máquina

- Cabezal vertical

- Dispositivo de cambio de herramientas

- Pinza doble

- Nc mesa giratoria basculante

- Eje c de la mesa: d 650 mm, integrado en la mesa fija 800 mm x 650 mm

- Rango de giro eje c 360° rango de giro eje a: +120°/-120

Más información

4.311h (Horas husillo) // 2.339h (Horas rayo láser) // Documentación disponible

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

Documentos

José María García

Opciones de pago

Pago por adelantado

Financiación de activos