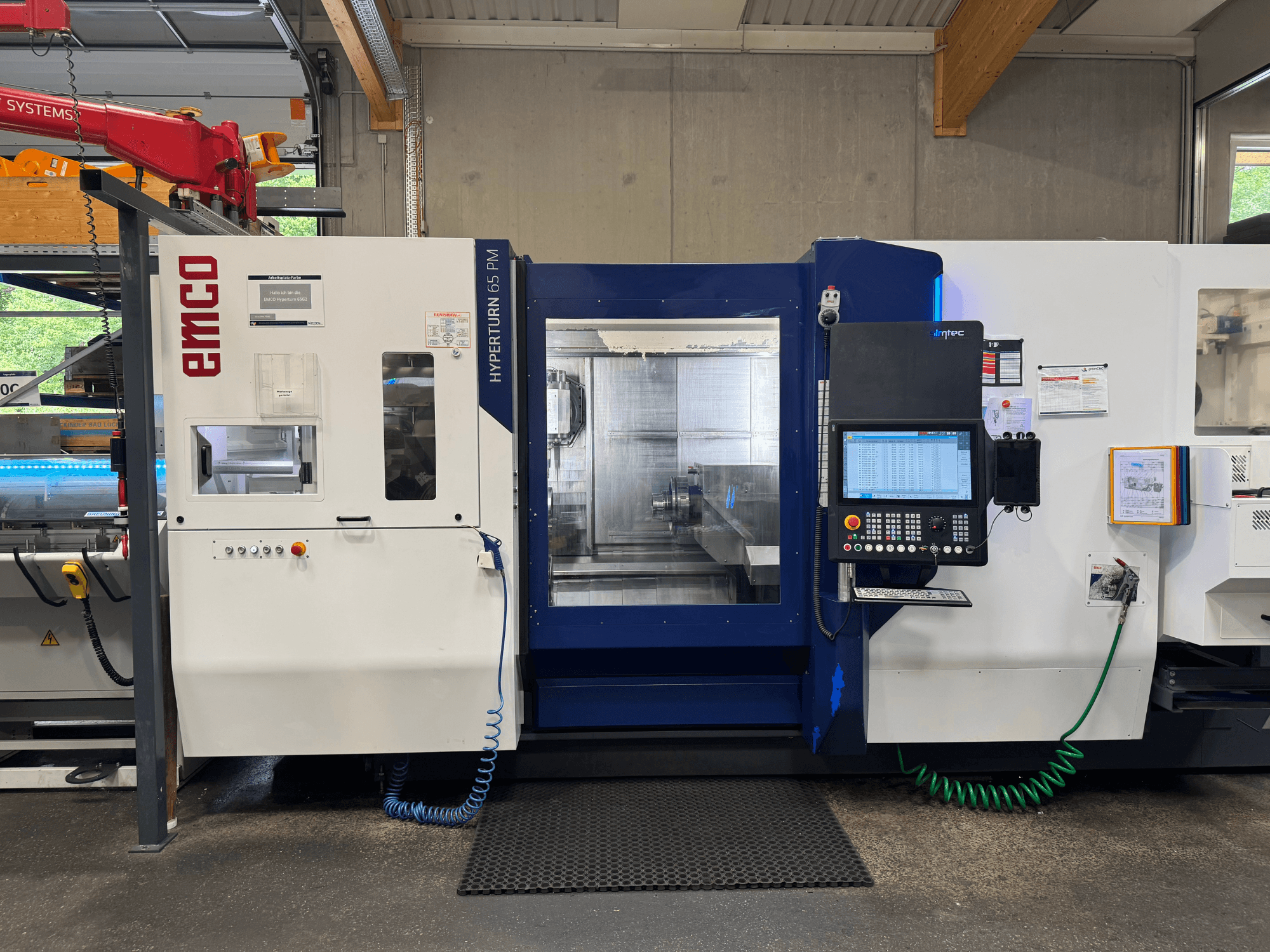

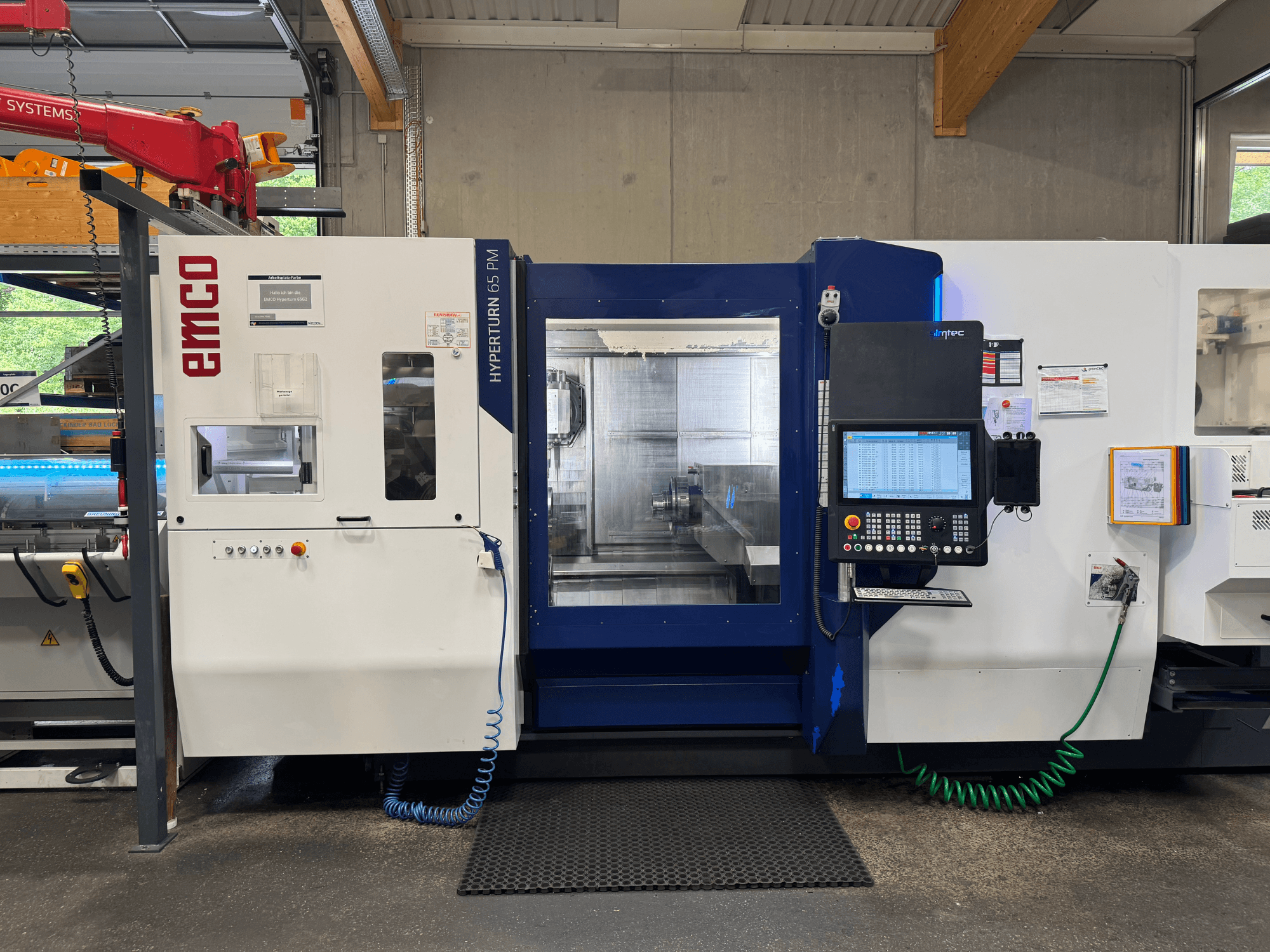

EMCO - Hyperturn 65 Powermill G2AT-TUR-EMC-2022-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Centro de torneado y fresado EMCO Hyperturn 65 Powermill G2 usado

Este EMCO Hyperturn 65 Powermill G2 de 6 ejes se fabricó en 2022. Se trata de un centro de torneado y fresado CNC muy productivo que cuenta con un husillo principal y un subhusillo con un par máximo de 250 Nm y velocidades de hasta 5000 rpm. El husillo de fresado ofrece hasta 12000 rpm. Incluye un almacén de herramientas de 40 posiciones, una torreta de 12 posiciones y el avanzado sistema de control Sinumerik ONE. Si está buscando obtener capacidades de torneado y fresado de alta calidad considere la máquina EMCO Hyperturn 65 Powermill G2 que tenemos a la venta. Contacte con nosotros para más información.

Resumen

- marca: EMCO

- año: 2022

- MODELO: Hyperturn 65 Powermill G2

- tipo de aplicación: Torneado

- Ubicación: Austria

- tipo de máquina: Centro de torneado y fresado

Información técnica - EMCO Hyperturn 65 Powermill G2

Dimensiones

- Peso de la máquina: 620 kg

Recorrido

- Número de ejes: 6

Especificación Técnica

- Potencia del husillo: 29 kW

- Velocidad del husillo: 5000 RPM

Información adicional

Husillo principal (accionamiento directo):

Par máx.: 250 Nm

Subhusillo (accionamiento directo):

Potencia motriz máx.: 29 kN (según suministro)

Par máx.: 250 Nm

Rango de velocidad: 0-5000 rpm

Husillo de fresado (accionamiento directo):

Potencia motriz máx.: 37 kW

Par máx: 30 Nm

Rango de velocidad: 0-12000 rpm

Torreta de herramientas (accionamiento directo):

Potencia motriz máx.: 10 kW

Par máx: 30 Nm

Rango de velocidad: 0-12000 rpm

Cinemática y ejes:

Carro transversal en la parte superior con husillo de torneado/fresado como husillo motor; sujeción hidráulica durante el torneado

Recorrido del eje Y: +/- 120 mm

Eje B con accionamiento directo: +/- 120°, sujeción hidráulica

Herramientas:

Almacén de herramientas de 40 posiciones, HSK-T63

Torreta radial de 12 posiciones con accionamiento directo, interfaz de herramienta BMT55P

Husillos y amarre:

Cilindro de sujeción alta con tubo de tracción para el husillo principal

Cilindro de sujeción total con sujeción parcial hueca de 66 x 550 mm de profundidad en el contrahusillo

Presión de amarre programable para husillo principal y contrahusillo

Enjuague de avance externo en husillo principal y contrahusillo

Freno de retención mecánico en husillo principal y contrahusillo

Eje C para husillo principal y contrahusillo

Control y HMI:

SINUMERIK ONE / OPERATE, interfaz de usuario basada en la aplicación EMCONNECT

Pantalla multitáctil de 22

IPC con 240 GB

Programación por diálogo SHOPTURN

Simulación y dibujo 3D

Detección de material residual

Desbloqueo desde memoria externa

Lector CAD (importación DXF)

TRANSMIT y TRACYL para la programación del eje C

Interfaz USB, unidad de red (Ethernet)

Teclado PC incl. hotkey HMI

Barra de estado LED

Fluidos y utilidades

2 líneas de refrigerante a 25 bar

2 bombas de lavado a 4,3 bar

Unidad de aire acondicionado del armario de control

Sistema de refrigeración para motores de husillo, husillo de fresado, motor de par del eje B y accionamiento directo de la torreta

Unidad hidráulica

Luz de la máquina

8 elementos de nivelación

Retroalimentación/medición:

Escalas de vidrio: X1 (incl. sistema de aire), Y1, Z1, X2 (HT65-PM-G2 / 840D-sl)

Equipamiento adicional

Gestión y filtración de virutas:

Cinta transportadora de virutas con bisagras, altura de descarga de 1200 mm

Sistema de filtro de cinta, 980 litros

Bomba de agua sucia

Opciones de control/supervisión:

Volante electrónico BAOD-SL (portátil, montaje magnético para controladores Siemens)

Control de rotura y desgaste de herramientas EMCO / B40D-SL

Sonda inalámbrica / control de rotura de brocas HSK BK-MICRO

Torneado en 4 ejes / corte de equilibrio (opción SINUMERIK)

Velocidad de husillo de extremo alternativo (opción SINUMERIK)

Torreta como contrapunto (opción SINUMERIK)

Contrahusillo como contrapunto (opción SINUMERIK)

Alimentador de barras (especificaciones suministradas):

Longitud de la barra: 300-1200 mm

Diámetro de la barra: 10-104 mm

Superficie de apoyo del material (vista frontal) 800 x 1250 mm

Capacidad de material: 12 barras de 65 mm de diámetro

Capacidad de carga máx.: 400 kg (máx. 74 kg/barra)

Material rectangular: longitud de borde mín. 6 mm; circunferencia máx. 105 mm

Material hexagonal: SW 5 a 85 mm

Material redondo: <15 mm

Profundidad de retracción de la barra de empuje: 1470 mm

Alimentación eléctrica: 24 V CC (interfaz)

Dimensiones: longitud 1800 mm; anchura 1315 mm

Altura carro/husillo: 1090-1330 mm

Peso: aprox. 620 kg

Accesorios:

Spannfutter, Hainbuch Centrotex M Schnell Wechselsystem.

Axzug SE100

Axzug SE65

Axfix SE 65

Axfix SE100

Span Dorn T210 GR0

4 Bachen Futter INOFlex® VT-S 016 ( 160 futter)

Warenwert ca.: 70.000€

Sowie BMT 55 Halter Unten

Und 40Hsk Aufnahmen ( Warenwert ca.: 30.000)

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos