Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

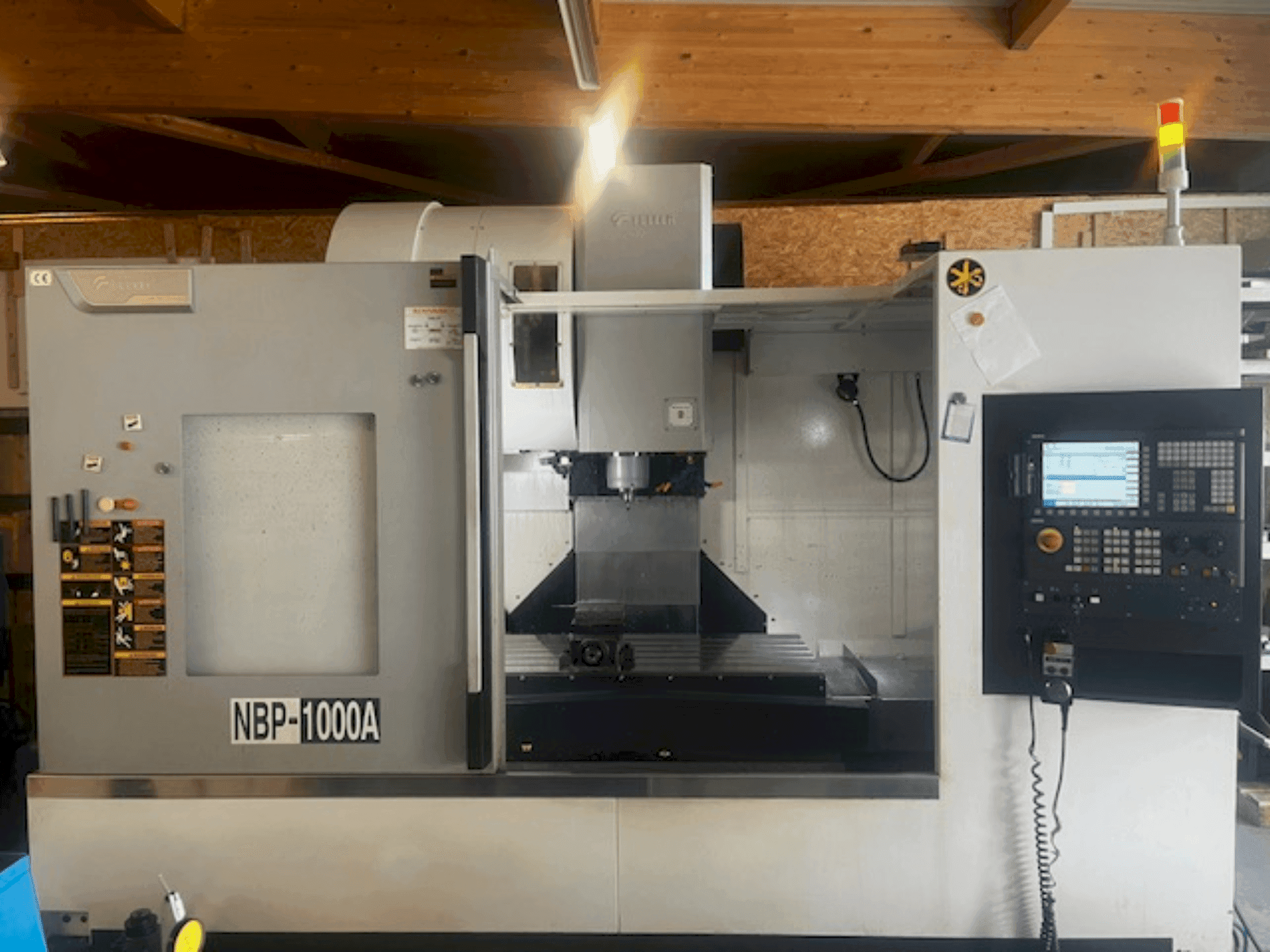

Feeler - NBP 1000ADE-MIL-FEE-2016-00002

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Venta de Feeler NBP 1000A usados | gindumac.com

Este centro de mecanizado vertical Feeler NBP 1000A de 3 ejes se fabricó en 2016. Presenta una estructura robusta con fundición de lamella fina Meehanite y guías con tratamiento térmico para un rendimiento de mecanizado superior. El husillo funciona a 10 000 rpm, soportado por rodamientos de bolas de contacto angular y una unidad de refrigeración con control de temperatura. Incluye un almacén de herramientas de 30 estaciones con un cambiador de doble brazo y un sistema de control Siemens Sinumerik 828D. Considere la oportunidad de adquirir este centro de mecanizado vertical Feeler NBP 1000A. Contacte con nosotros para más información.

Resumen

- marca: Feeler

- año: 2016

- MODELO: NBP 1000A

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado vertical

- Marca de unidad de control: SIEMENS

Información técnica - Feeler NBP 1000A

Unidad de Control

- Marca del control: SIEMENS

- Modelo del control: Sinumerik 828D

Recorrido

- Número de ejes: 3

- Recorrido eje X: 1000 mm

- Recorrido eje Y: 610 mm

- Recorrido eje Z: 600 mm

Especificación Técnica

- Max. Tool Weight: 8 kg

- Potencia del husillo: 22.5 kW

- Velocidad del husillo: 10000 RPM

Información adicional

Equipamiento adicional

- Presión de la bomba: 30 bar

- Filtro de cartucho para proteger la alimentación rotativa del husillo

- Completamente cerrado con grandes puertas y acceso para mantenimiento

- Preparado para la extracción de neblina de aceite (Ø 200 mm)

- Boquillas de lavado en ambos lados

- Transportador de tornillo/cinta articulada

- Cubo para virutas incluido

- Eyector a la izquierda, montado en la parte delantera

Beneficios de la máquina

Ventajas cualitativas de la máquina

- La puesta en servicio fue en 2018

Ventajas técnicas de la máquina

- Husillo robusto con tratamiento térmico (58-62 hrc)

- Unidad de refrigeración a temperatura controlada para la estabilidad térmica

- Rodamientos delanteros: 4 rodamientos de bolas de contacto angular (Ø 70 mm)

- Rodamientos traseros: 2 rodamientos de bolas de contacto angular (Ø 60 mm)

- Accionamiento principal siemens 1ph8133

- Par: 143 nm a un ciclo de trabajo del 40% (hasta 1500 rpm)

Más información

Ampliaciones opcionales: Preparación de la mesa giratoria: Interfaz para mesa giratoria NC (sin módulo de eje/servoaccionamiento) Medición de piezas: Sonda Renishaw OMP60 Contacto, transmisión óptica de la señal Bola de rubí Ø 6 mm, longitud 50 mm IPX8, funcionamiento con batería Incluye módulo de transmisión OMI-2T Nota: Portaherramientas no incluido en el suministro. Opcional: compresor de tornillo. Unidad de control SIEMENS Sinumerik 828D LCD en color de 10,4 Interfaz de usuario: SINUMERIK Operate con ShopMill Dimensiones de la guía: Eje X: Ancho de guía 90 mm, distancia entre guías 450 mm Eje Y: Ancho de guía 143 mm, distancia entre guías 1210 mm Eje Z: Ancho de guía 90 mm, distancia entre guías 450 mm Herramientas Espárrago de tracción: DIN 69872 (SK 40) Almacén de herramientas: Almacén de herramientas de 30 estaciones Cambiador de herramientas de doble brazo, tiempo de cambio: 2,5 s Unidad de inyección Sistema de refrigeración: Refrigeración por inundación con boquillas anulares alrededor del husillo principal Presión de la bomba: 2,5 bar, caudal 85 l/min Depósito separado: 250 litros Retorno de aceite deslizante integrado

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos