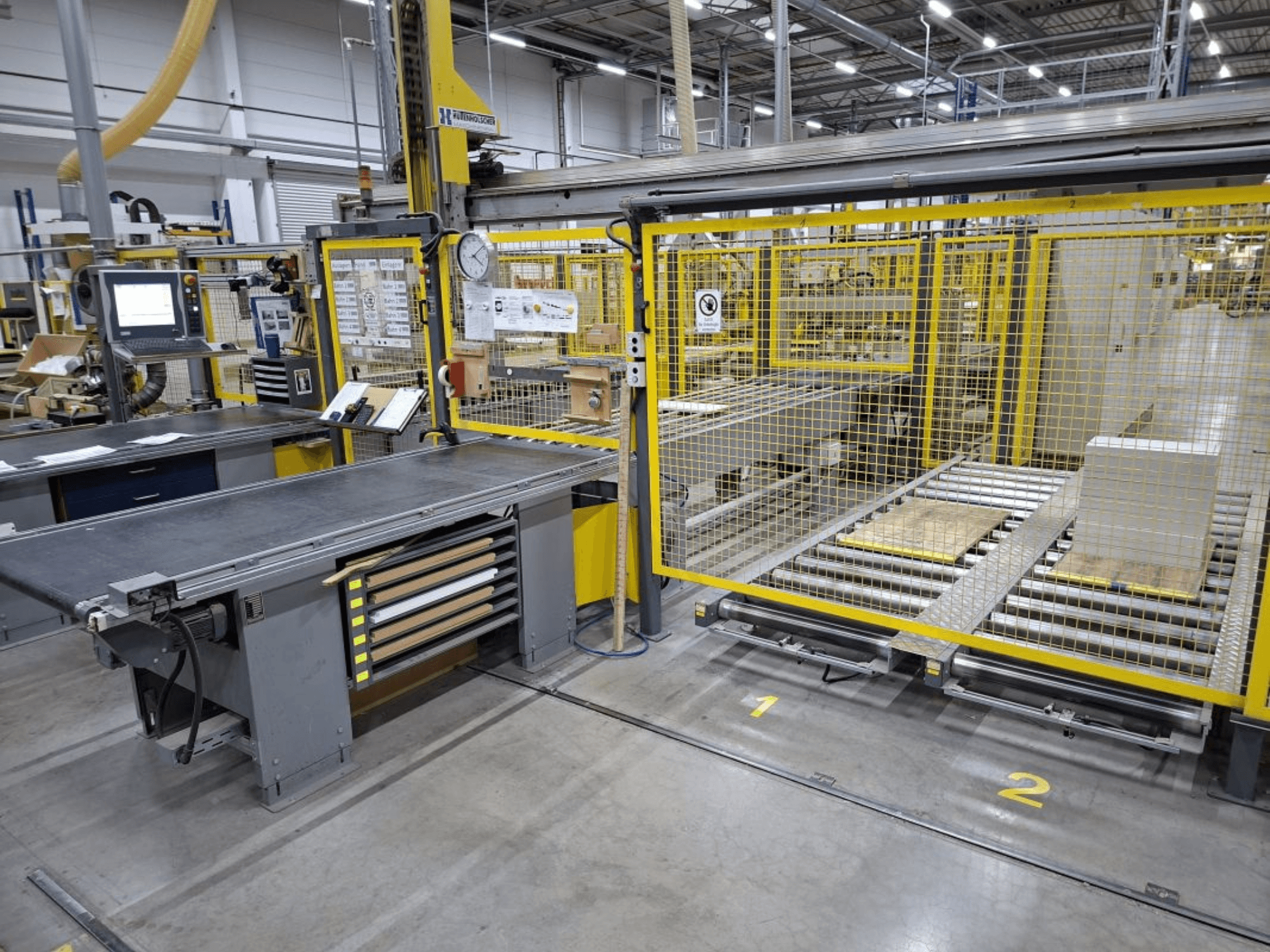

Hüttenhölscher - LineDE-BOR-HUT-2012-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para madera

- ➤ Used Hüttenhölscher Line For Sale | gindumac.com

This Hüttenhölscher Line multi-spindle drilling machine was manufactured in 2012. It features a PC-controlled function sequence under Windows 7 with TwinCAT, a 6-station loading gantry, and a 2-axis gantry robot. The machine includes a vacuum generation by ejector and multiple conveyor lines for efficient material handling. Ideal for high precision drilling with its advanced control system. Contact us for more information about this machine.

Resumen

- marca: Hüttenhölscher

- año: 2012

- MODELO: Line

- tipo de aplicación: Perforación (madera)

- Ubicación: Alemania

- tipo de máquina: Máquina taladradora multihusillos

Información técnica - Hüttenhölscher Line

Dimensiones

- Longitud de la máquina: 2250 mm

Información adicional

Control: PC-controlled function sequence under Windows 7, TwinCAT

Part dimensions:

Length: 300–2250 mm

Width: 350–710 mm

Thickness: 16–25 mm

2-station drilling station:

Base frame as welded construction with machined screw-on surfaces

2x toothed belt conveyors V = 1.5 m/sec

2x pneumatic lift for toothed belt conveyors

2x stoppers for cabinet parts, dampened by shock absorbers

2x pneumatic double clamping cylinders, controlled by ball screw and servo motor, moved to side height (measuring the side height)

2x pneumatic cross alignment ruler (plausibility check)

2x vacuum clamping units in the drilling machine table

2x 0-line controllable

Support:

Support can be moved in the X direction by means of a servomotor

2x drilling gear (support 1):

Support equipped with 2 units (machining from above)

Individually movable in Y direction by servomotor

Individually movable in Z direction by servomotor

Drilling gear a = 32 mm, adjustable with frequency converter, drill chuck Ø 10h7 with grub screw

Callable spindles, 8000 rpm

Two 16-spindle drilling gears

Groove saw (support 1):

Sawing units for cutting special rear wall grooves

Sawing unit with tool holder, speed control via frequency converter

Pneumatically pilot-controlled working position

2x milling spindles right/left at the front edge (support 1):

Pneumatically pilot-controlled working position

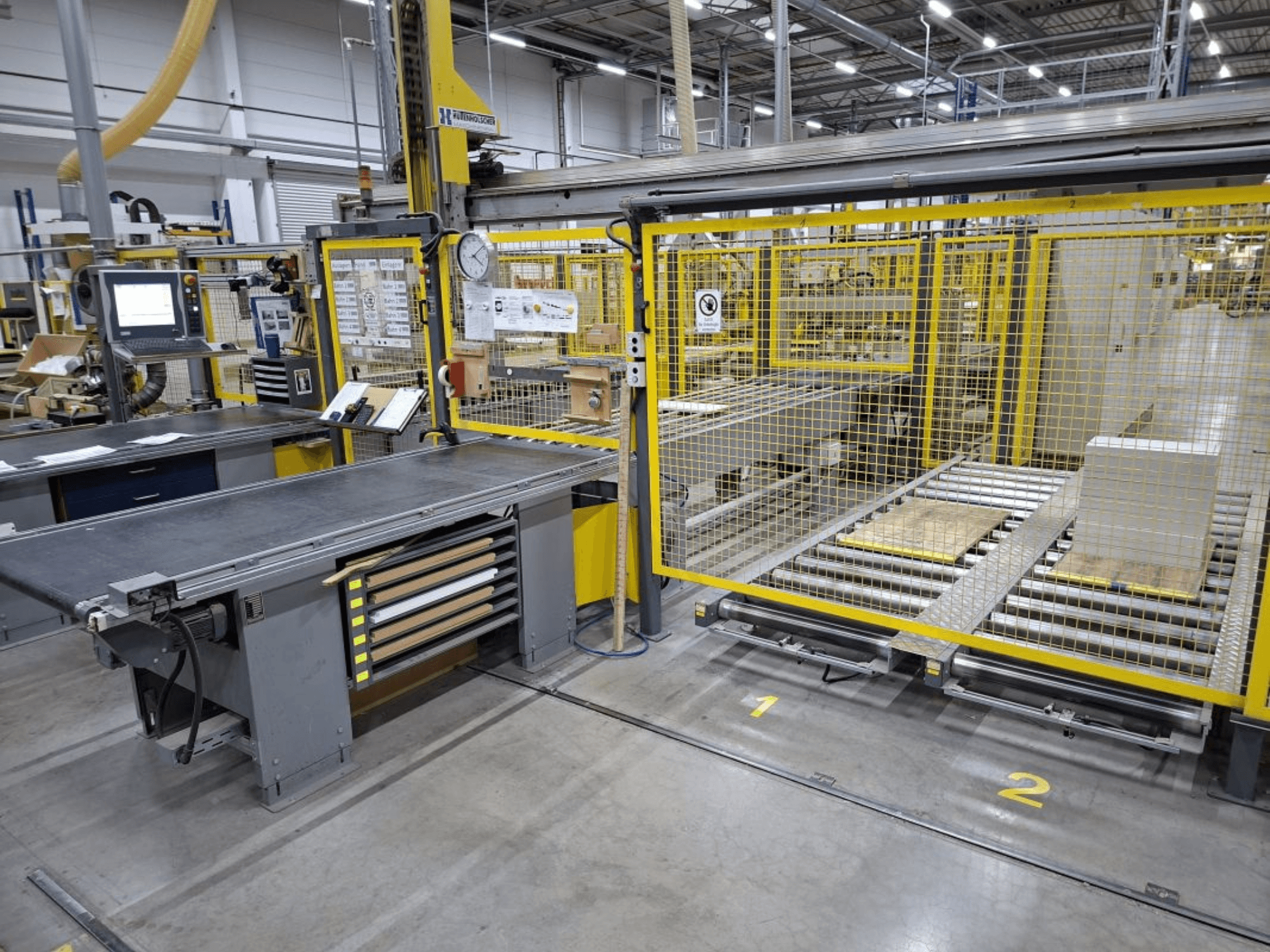

Additional equipment (automation, handling, guarding, conveyors)

Loading/handling:

6-station loading gantry

2-axis gantry robot; Y/Z axes with servo motors; travel distances: Y-axis 8500 mm, Z-axis 1500 mm

Suction crossbeam with four-circuit vacuum supply; vacuum generation by ejector

Double part detection

Portal supports

4 stacking stations

1 hand rest station (automatic/manual feeding)

1 removal station (automatic/manual removal)

Side feed range:

Stack height: max. 1000 mm (60 parts) incl. protective plate

Protective plate sizes:

1380 mm x 780 mm

1220 mm x 720 mm

1120 mm x 620 mm

2290 mm x 620 mm

Thickness: 25 mm

Thickness: max. 28 kg

Floor roller conveyor / stack feed:

4 roller conveyor lines, 930 mm wide x 3600 mm long, AH 300 mm

Feeding/removal: manual cross transfer carriage

Support stations / automatic feeding:

Transport section 950 mm wide x 4100 mm long; integrated side stop

Manual feeding:

Toothed belt section 900 mm wide x 2500 mm long

Transfer shuttle:

Toothed belt section 900 mm wide x 2500 mm long; horizontal stroke approx. 2500 mm by three-phase motor

Return:

Transport section 950 mm wide x 4000 mm long; pneumatic stopper

90° rotary unit:

Vacuum suction cup; pneumatic stroke; rotation by three-phase motor by +/- 90°

Discharge stations / automatic removal:

Transport 950 mm wide x 3000 mm long; positioning of cabinet parts by encoder

Manual removal:

Toothed belt section 900 mm wide x 3000 mm long

Protective system for feeding:

45 m protective fence with 3 access doors

2 sliding doors for feeding the floor roller conveyors

Input, request, and release by acknowledgment

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos