Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

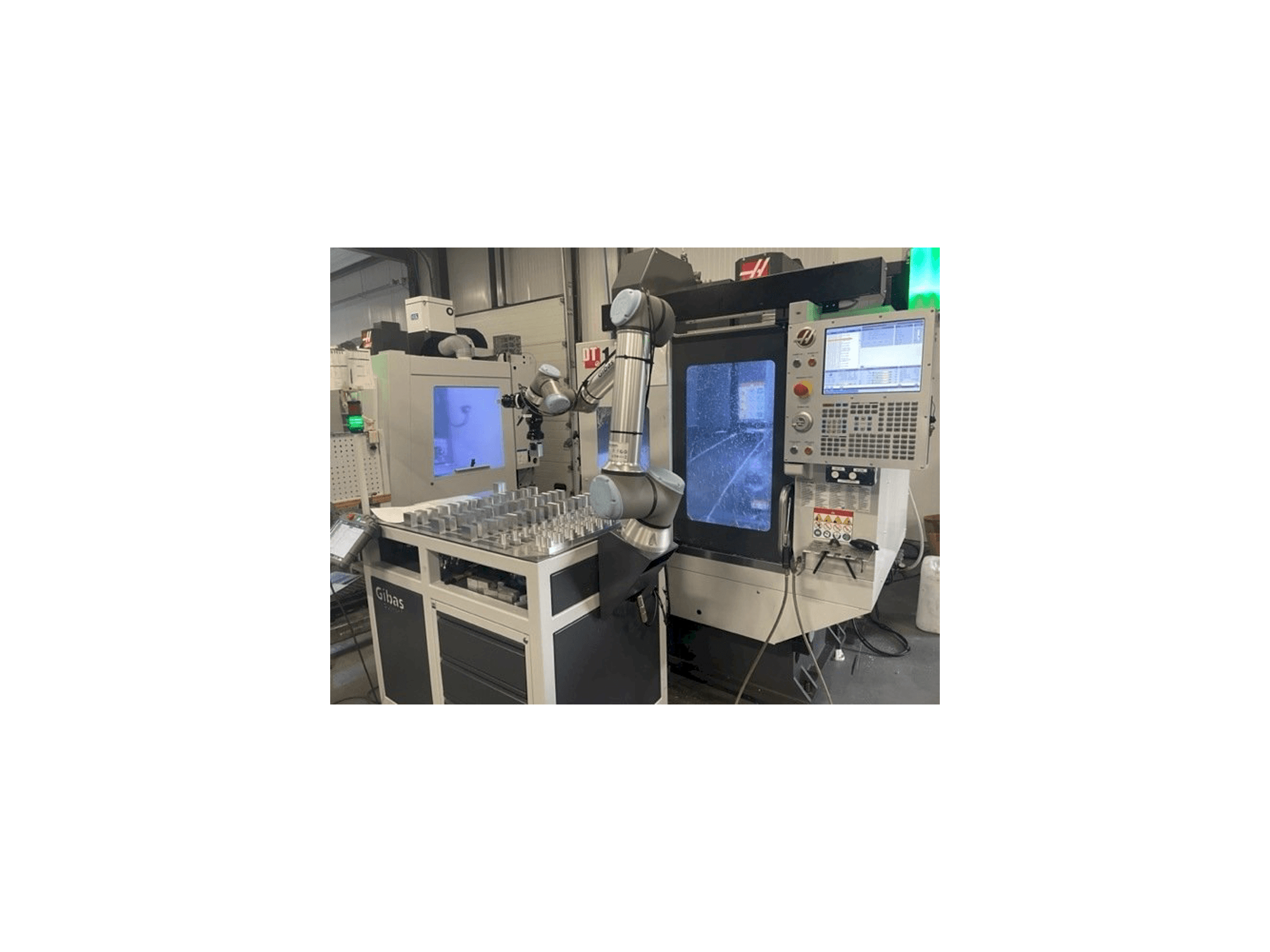

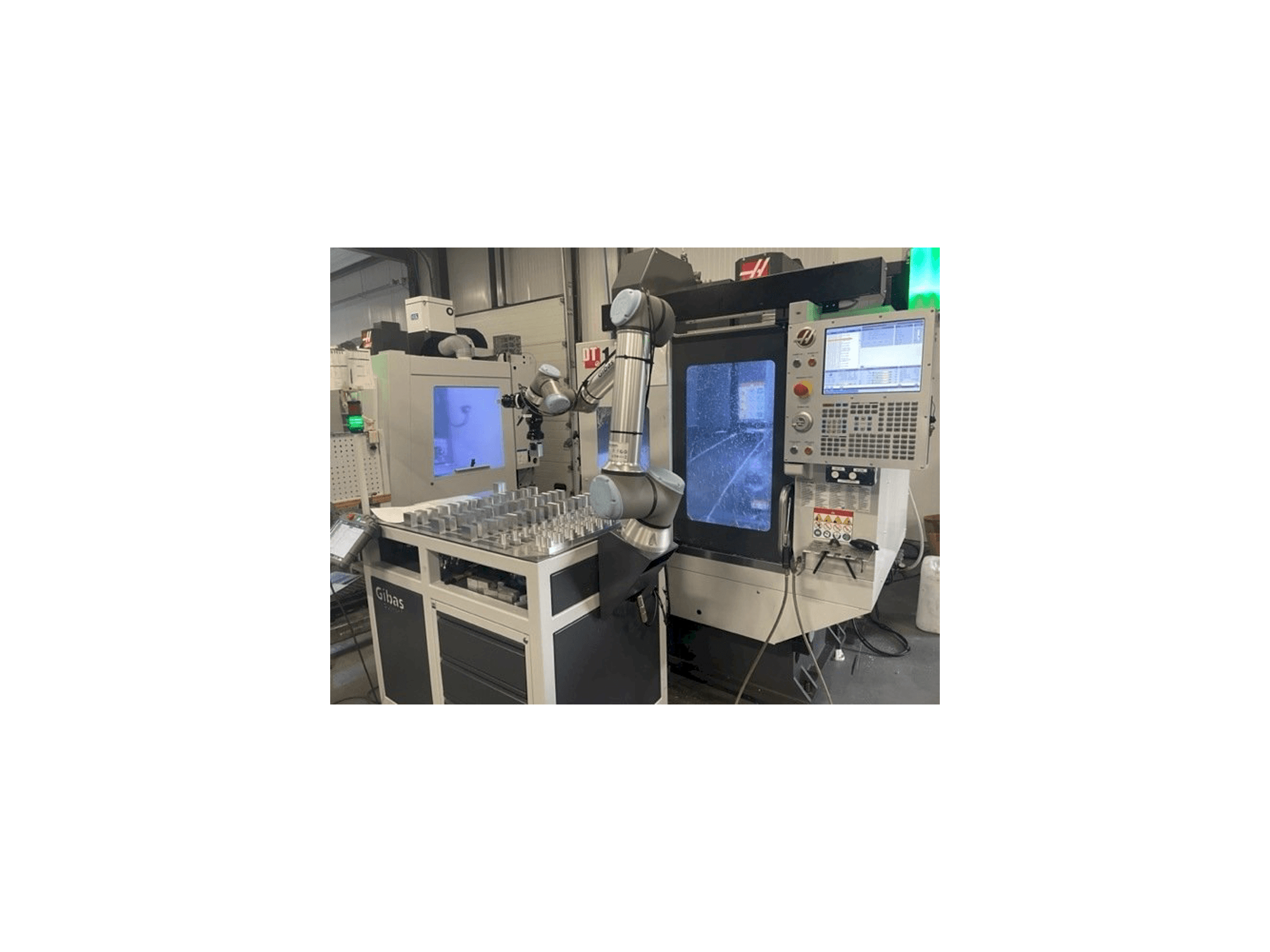

HAAS - DT-1 with Universal Robot UR10E Automation CellNL-MIL-HAA-2018-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- HAAS DT-1 Vertical Machining center with Universal Robot UR10E Automation Cell

This HAAS DT-1 Vertical Machining center with Universal Robot UR10E Automation Cell was manufactured in the year 2018 in Germany and has 3179 production hours. It is equipped with a HAAS control unit and has 5 axis. The machine has a spindle speed of 15000 rpm. It comes with a universal robot UR10E automation cell included in the scope of delivery.

Resumen

- marca: HAAS

- año: 2018

- MODELO: DT-1 with Universal Robot UR10E Automation Cell

- horas de producción: 3179

- tipo de aplicación: Fresado

- Ubicación: Países Bajos

- tipo de máquina: Centro de mecanizado vertical

- Marca de unidad de control: HAAS

Información técnica - HAAS DT-1 with Universal Robot UR10E Automation Cell

Unidad de Control

- Marca del control: HAAS

Recorrido

- Número de ejes: 5

Especificación Técnica

- Velocidad del husillo: 150000 RPM

Información adicional

Machine Benefits

Qualitative Machine Benefits

- Visual programming system

- Automatic door (delivered by gibas)

Technical Machine Benefits

- 21 tool warehouse

- 20 bar cooling through the spindle / through-spindle coolant ready + through spindle coolant (tsc)

- Air through the spindle (through tool airblast (tab)

- 4th and 5th axis drive

- Wireless intiuitive probe system

- Programmable coolant nozzle

- Chip auger / chip conveyor

- Haas connect

- Dwo/tcpc (dynamic work offsets and tool center point control)

- High speed machining option

Extra Information

INCLUDING UNIVERSAL ROBOT UR10E AUTOMATION CELL: 10 KG, 1300mm reach Repeat accuracy of the robot +/- 0.05mm 6 axles. Clamping installation including various jaws and grippers for different shapes, such as round products Various grid plates Grid table on wheels. Robot, controller, touchscreen control unit and the cables between them • Software (GUI) • Table with storage space for the controller and a mounting point for the touchscreen • Positioning system for products (incl. warehouse for product carriers) • 1 double pneumatic gripper • Tool nose camera from Robotiq, for 2D product recognition and random picking • Blow-off unit (incl. valve) • Compressed air treatment unit • Signal tower • Position triangle products, with product presence sensorVision system - • Interfacing and automating existing door: Complete clamp centering clamping system SMW car block with various jaws.

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos