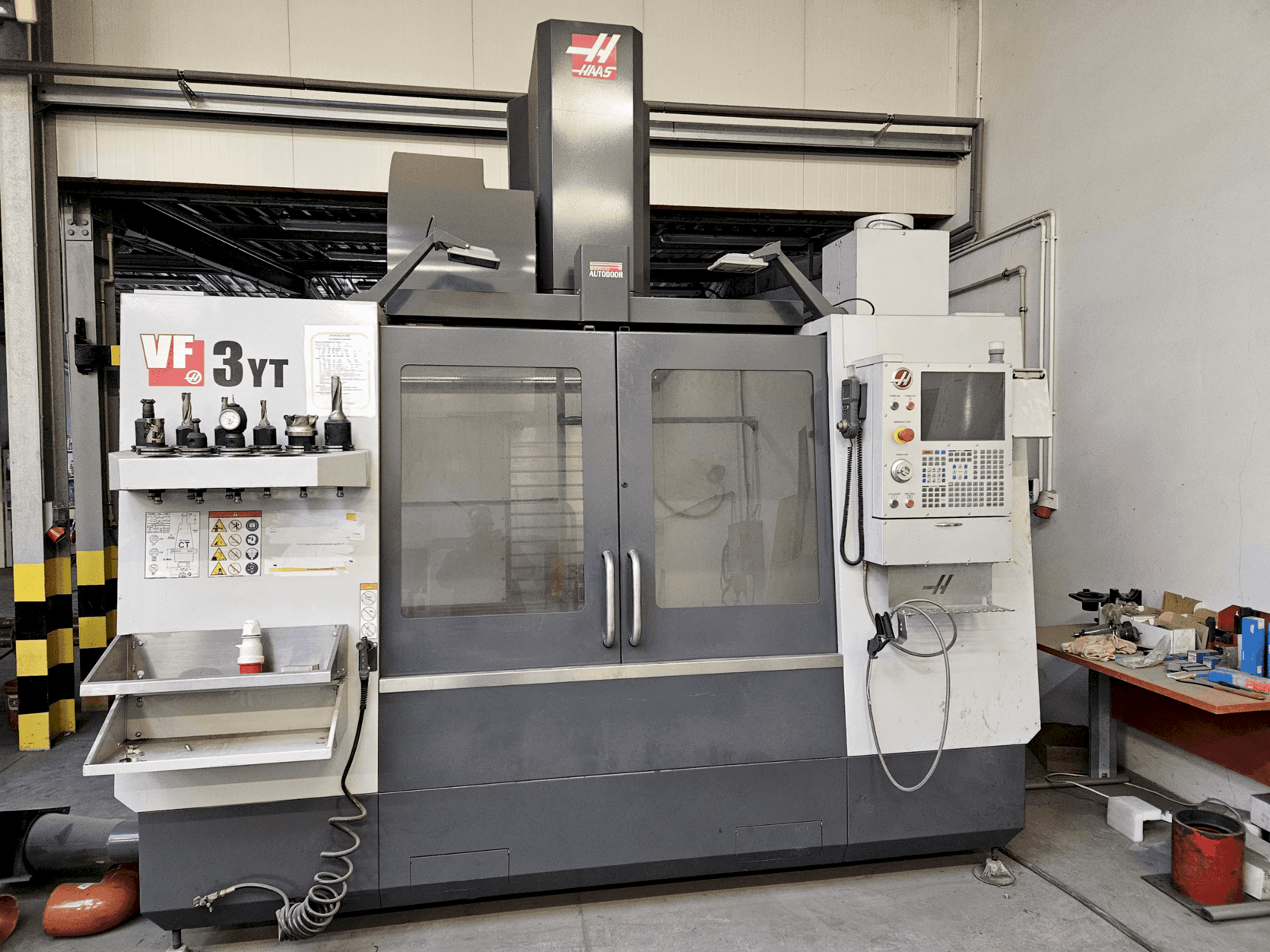

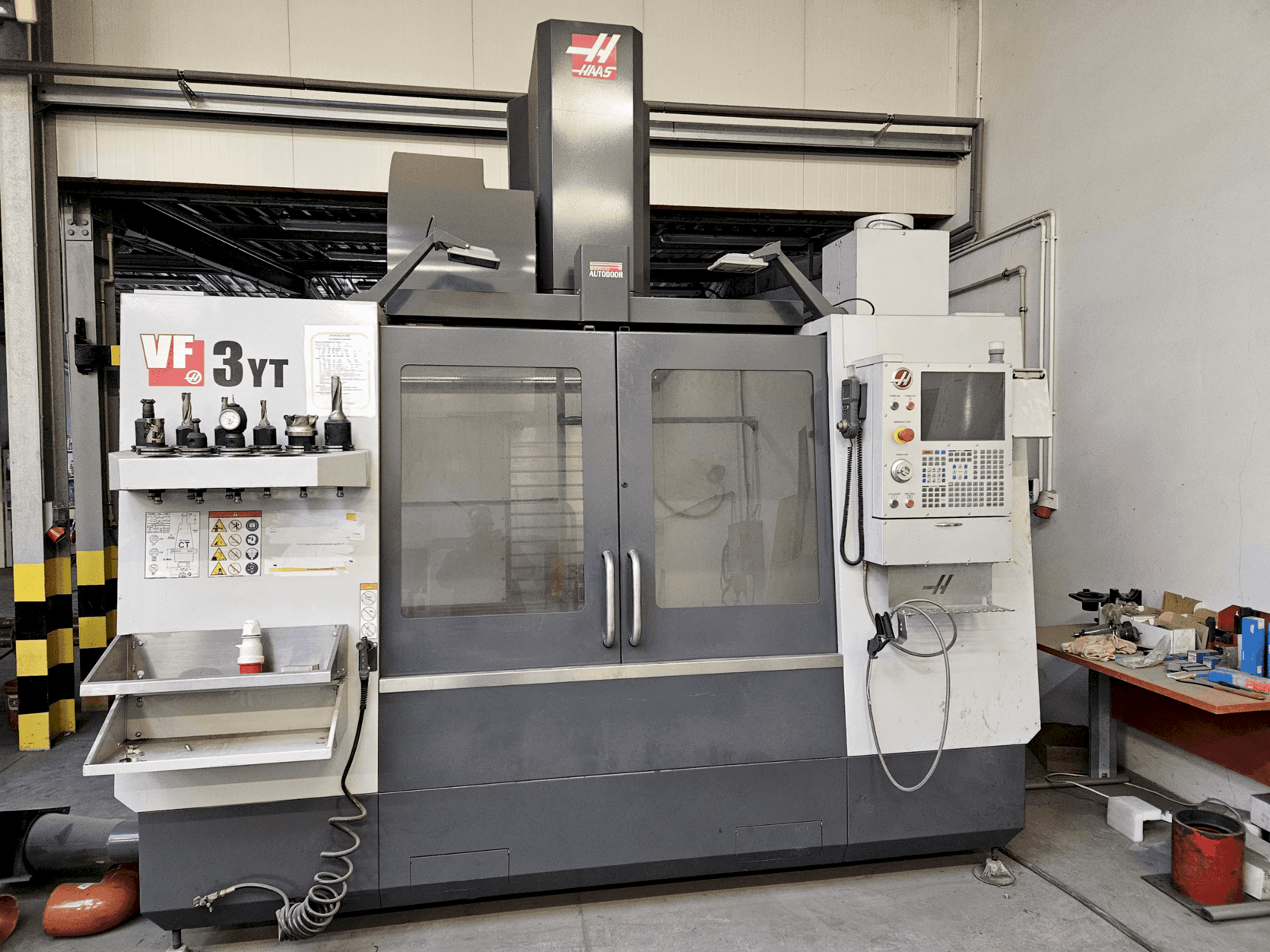

HAAS - VF-3YT/50PL-MIL-HAA-2017-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- Centro de mecanizado vertical HAAS VF-3YT/50

Este centro de mecanizado vertical HAAS VF-3YT/50 fue fabricado en el año 2017 en Estados Unidos y tiene 238 horas de producción. Está equipado con una unidad de control HAAS y tiene 3 ejes. La máquina tiene una velocidad de husillo de 12000 rpm.

Resumen

- marca: HAAS

- año: 2017

- MODELO: VF-3YT/50

- horas de producción: 238

- tipo de aplicación: Fresado

- Ubicación: Polonia

- tipo de máquina: Centro de mecanizado vertical

- Marca de unidad de control: HAAS

Información técnica - HAAS VF-3YT/50

Unidad de Control

- Marca del control: HAAS

Dimensiones

- Peso de la máquina: 7212 kg

- Largo de mesa: 1372 mm

- Ancho de mesa: 610 mm

Recorrido

- Número de ejes: 3

- Recorrido eje X: 1016 mm

- Recorrido eje Y: 660 mm

- Recorrido eje Z: 635 mm

Especificación Técnica

- Número de herramientas: 30

- Velocidad del husillo: 7500 RPM

Información adicional

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Transportador sinfín de virutas

- Soplado del cono del husillo

- Corte de roscas sin mandril de compensación

- Instalación para conexión de aire comprimido

- Módulo de detección precoz de fallos de alimentación

- Posición del ángulo de la boquilla del refrigerante programable

- Mando a distancia colgante con pantalla lcd /manivela/

- Sistema de refrigeración con depósito de refrigerante extraíble

- Sistema automático de lubricación centralizada

- Sistema de palpado inalámbrico wips-r para medición de herramientas en radio y longitud, para medición y reglaje de piezas con ciclos de medición. Incluye so, macro, coord y vps (sistema de programación visual).

Ventajas técnicas de la máquina

- Refrigeración a través del husillo

- Cono de husillo iso50, tipo ct

- Capacidad de memoria 1 gb, tarjeta de red

- Haasconnect: control remoto del estado de funcionamiento de la máquina

- Monitor lcd de 15" y puerto usb

- Volante electrónico

- Sistema de refrigeración del husillo

- Compensación de temperatura para husillos

- Cabina protectora con puertas delanteras correderas y ventanas laterales abatibles

- Cargador de 30 posiciones

Más información

-CT Conicidad del husillo, tipo CT. -ACF Sistema de filtrado adicional de 25 μm, esencial para el mecanizado de fundición, aluminio, madera, plásticos con base de resina fenólica y otros materiales que generan polvo. -TSC* Refrigeración a través del husillo, bomba de alta presión /21 bar, 22 l/min/ (requiere opción ACF) -HIL Iluminación halógena adicional de la cámara -ENCL EXHAUST Sistema de extracción de neblina de aceite. Puede conectarse a una red de ventilación -WIFI Red inalámbrica -TAB Chorro de aire a través del husillo.

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos