Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

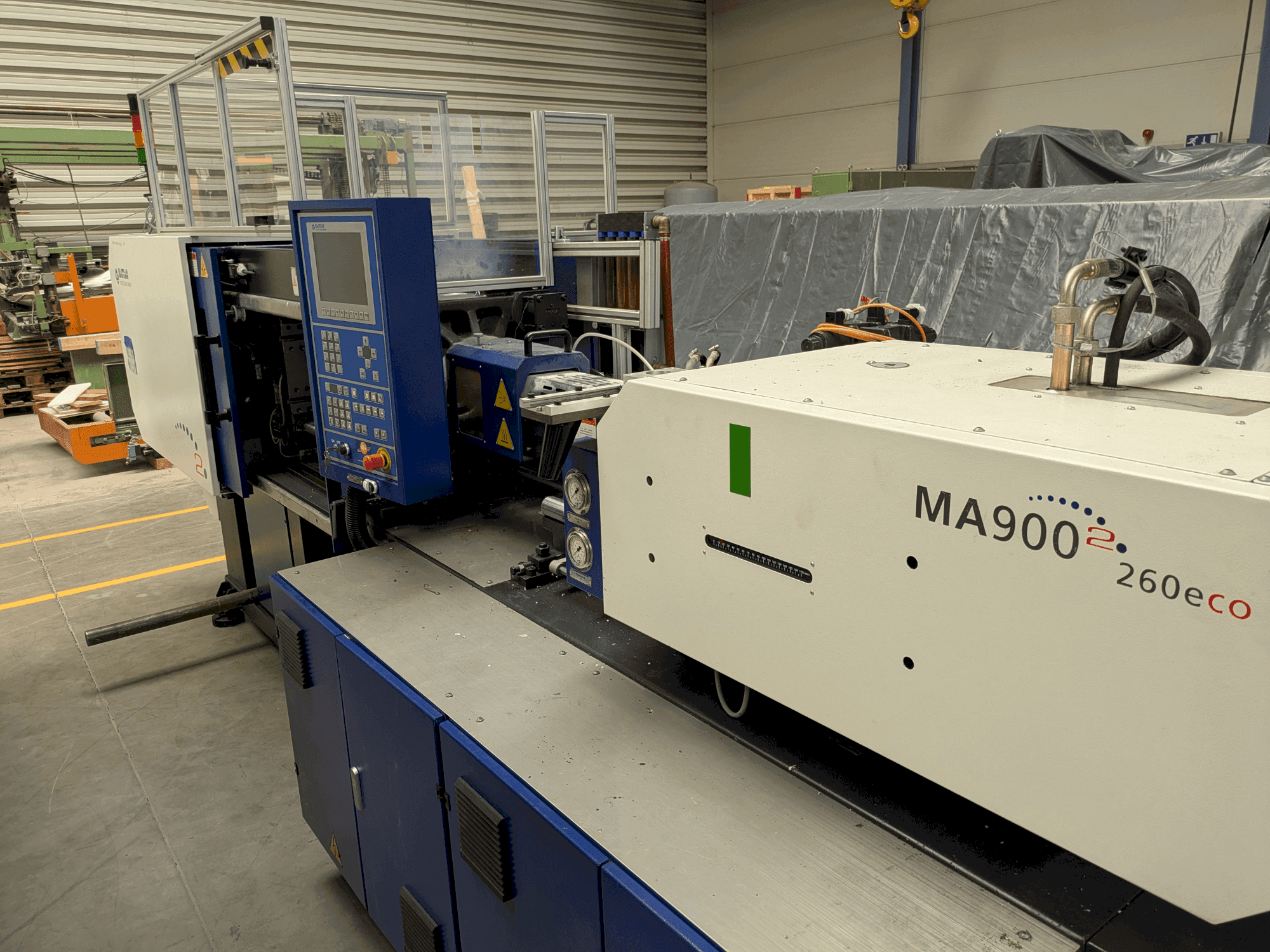

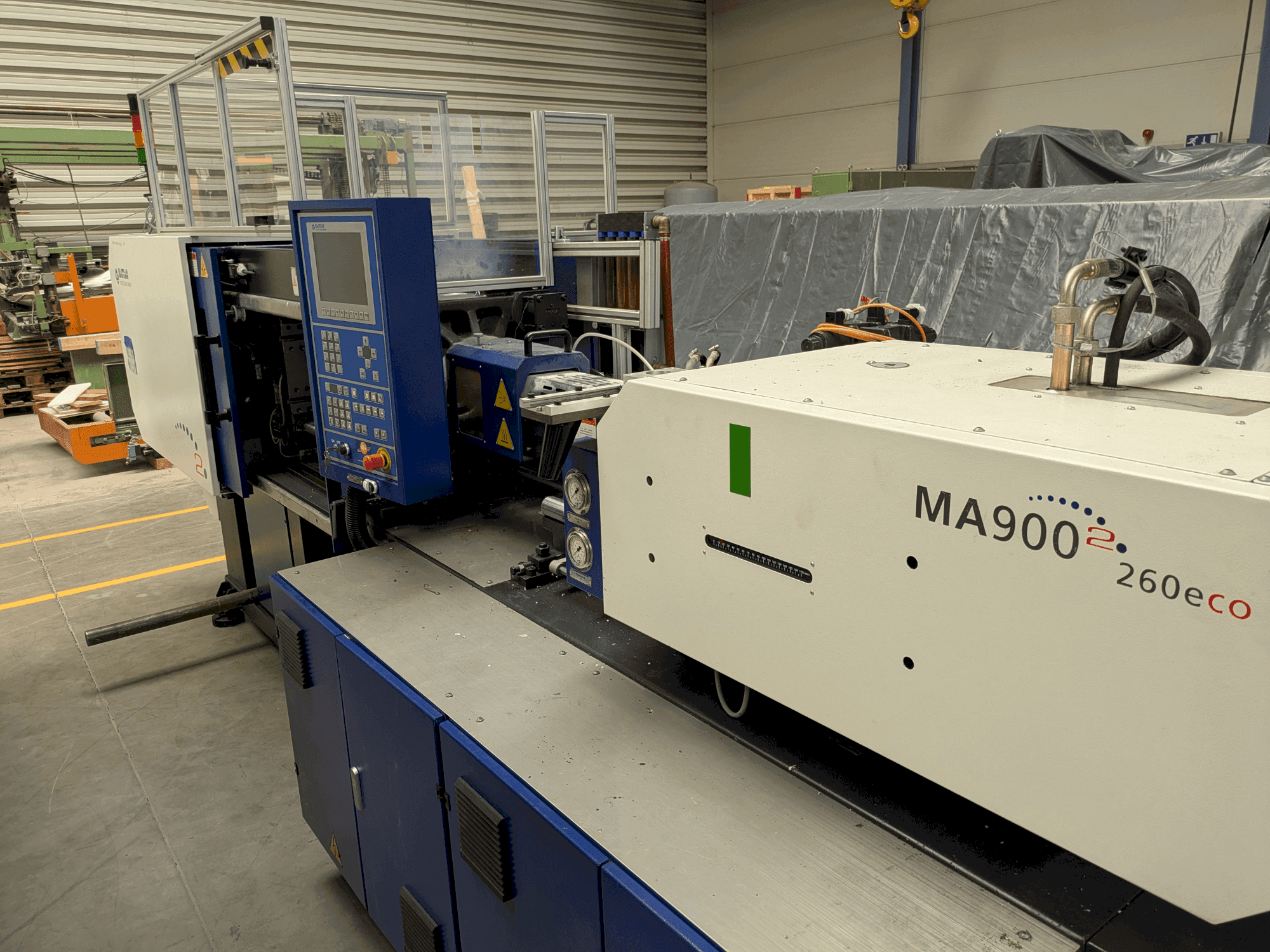

HAITIAN - MA900 II ecoDE-INJ-HAI-2016-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Maquinaria de procesamiento de plástico

- ➤ Venta de HAITIAN MA900 II eco usados | gindumac.com

Esta HAITIAN MA900 II eco se fabricó en 2016. Es una máquina de moldeo por inyección hidráulica con una fuerza de cierre de 900kN y un volumen de inyección de 153 cm3. Considere la oportunidad de comprar esta máquina de moldeo por inyección hidráulica HAITIAN MA900 II eco. Póngase en contacto con nosotros para obtener más información.

Resumen

- marca: HAITIAN

- año: 2016

- MODELO: MA900 II eco

- tipo de aplicación: Moldeo por inyección

- Ubicación: Alemania

- tipo de máquina: Máquina de moldeo por inyección hidráulica

Información técnica - HAITIAN MA900 II eco

Dimensiones

- Profundidad de la máquina: 4530 mm

- Altura de la máquina: 1910 mm

- Peso de la máquina: 3500 kg

Especificación Técnica

- Fuerza de cierre: 900 kN

- Diámetro del husillo: 36 mm

Información adicional

Capacidad de inyección (PS): 139 g

Capacidad de plastificación: 13,3 g/s

Potencia de calentamiento: 7. 85 kw

Distancia entre columnas (hxv): 360 × 360 mm

Altura de matriz disponible: 150 - 380 mm

Número de eyectores: 5

Potencia del motor de la bomba: 11 kw

Tamaño mínimo del molde (l×w) 250 × 250 mm

Espacio de instalación necesario: Debe dejar al menos 1 m de espacio libre alrededor de la máquina para su funcionamiento y mantenimiento

Diagrama de cimentación y estera de la máquina

Tipo de cimentación: Se recomiendan cimientos de hormigón armado.

Capacidad de carga: Debe soportar ≥ 3,5 t de peso de la máquina.

Tolerancia de nivel: La máquina debe instalarse sobre una cimentación nivelada (≤ 0,2 mm/m de pendiente).

Amortiguación de vibraciones: Utilizar almohadillas antivibración o placas de acero bajo los pies de la máquina.

Requisitos eléctricos y de cables

Potencia del motor de la bomba: 11 kW

Potencia de calefacción: 7,85 kW

Potencia total instalada (aprox.) ~19 kW

Suministro eléctrico: Trifásica, normalmente 400 V / 50 Hz (consulte las especificaciones locales).

Recomendación del disyuntor: ≥ 40 A (depende de las normas locales).

Conexión a tierra: Se requiere una conexión a tierra fiable (resistencia ≤ 4 Ω).

Diagrama de suspensión de cables: La máquina debe estar nivelada antes de conectar los cables

Requisitos hidráulicos y de refrigeración

Capacidad del depósito de aceite: 190 L (utilice aceite hidráulico recomendado ISO VG46).

Requisito de agua de refrigeración:

Para el enfriador de aceite hidráulico

Para los circuitos de refrigeración del molde (4 × conductos de agua suministrados)

Calidad del agua: Limpia, no corrosiva, filtrada.

Presión del agua: 0,2 - 0,4 MPa

Condiciones ambientales

Temperatura ambiente: 5 - 40 °C

Humedad relativa: ≤ 90% (sin condensación)

Lugar de instalación: Interior, entorno libre de vibraciones y polvo

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos