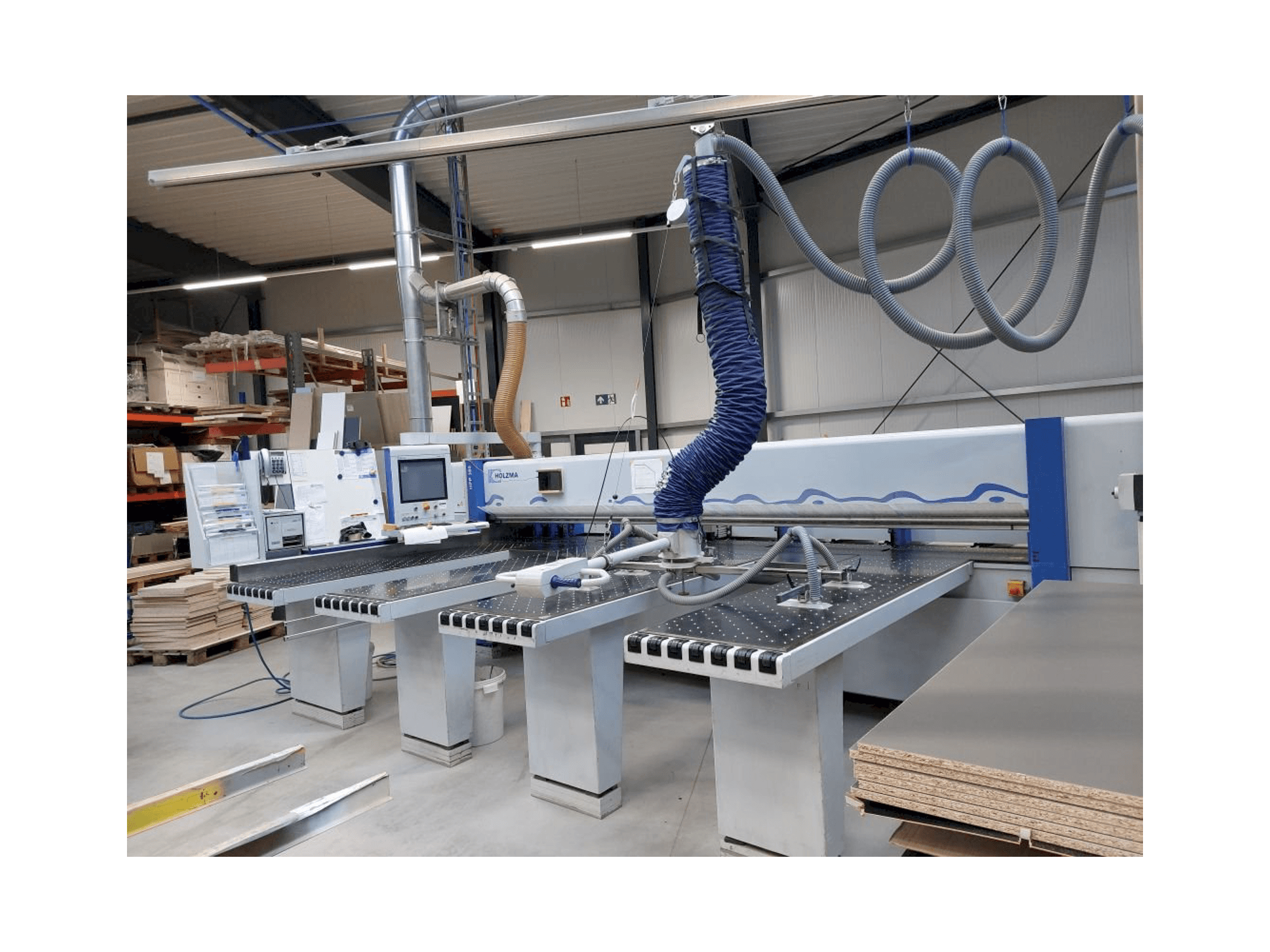

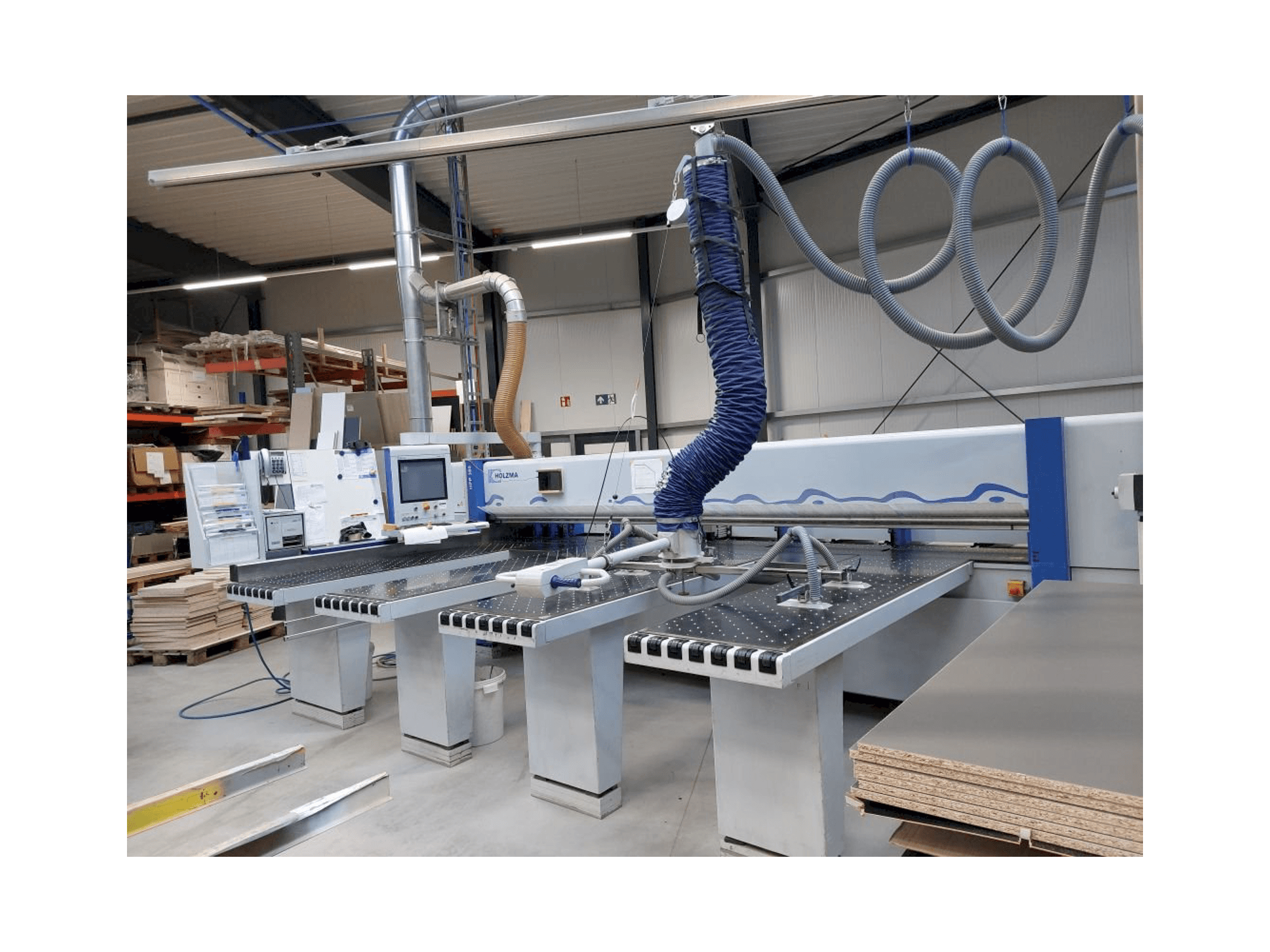

HOLZMA - HPP 380DE-SAW-HOL-2007-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para madera

- ➤ Usada HOLZMA HPP 380 - 2007 - Sierra En Venta | gindumac.com

Esta sierra de paneles HOLZMA HPP 380 se fabricó en 2007. Cuenta con un robusto carro de sierra de acero, sierras principales y de precorte, y un dispositivo patentado de retorno de ángulo central que reduce el tiempo de ciclo hasta en un 25%. La máquina está equipada con un sistema Power Control CADmatic 4, que garantiza un funcionamiento preciso y eficaz. La proyección de la hoja de sierra es de 95 mm, y funciona con un motor de sierra principal de 18,0 kW. Si desea más información sobre esta sierra de paneles, póngase en contacto con nosotros.

Resumen

- marca: HOLZMA

- año: 2007

- MODELO: HPP 380

- tipo de aplicación: Serrado

- Ubicación: Alemania

- tipo de máquina: Sierra de panel

Información técnica - HOLZMA HPP 380

Unidad de Control

- Modelo del control: CADmatic 4 - Professional

Información adicional

Equipamiento adicional

- Mesa de colchón de aire con elemento de rodillo 2160 x 650 mm: 4 piezas

- Soplador central: 1 pieza

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Certificado ce, certificado gs, certificado fph de polvo de madera

- División: 75/275/475/1050/1850/2650/3450 mm medidos desde la regla angular hasta el centro de la pinza de sujeción

- 2 pinzas de sujeción de dos dedos adicionales posibles

- 4 rastrillos manuales en pinzas de sujeción

- 1 pinza de sujeción de un dedo adicional posible

- Distancia entre chorros de las mesas de cojines de aire: 70 x 70 mm

Ventajas técnicas de la máquina

- Motor de la sierra de precorte: 2. 2 kw

- Tensión de funcionamiento: 400 v / 50 hz

- Valor de conexión eléctrica en el motor hs: 18. 0 kw = 24 kw, 21. 0 kw = 27 kw

- Precisión de posicionamiento: +/- 0. 1 mm/m

- Transporte de material respetuoso con la superficie, precisión de posicionamiento de por vida, no requiere lubricación, alta velocidad de deslizamiento del programa, no requiere mantenimiento, se mantiene la estabilidad total de la mesa de acero, sustitución fácil y económica de las placas de resina fenólica, desgaste mínimo de los cilindros, aplicación uniforme de la presión, corte mínimo = corte por rayado, ahorro significativo de tiempo de ciclo, calidad de corte superior, tiempos de preparación mínimos, reducción del tiempo de ciclo, fuerza de presión ajustable eléctricamente.

- Longitud de corte: 4300 mm

- Anchura de corte (recorrido de la corredera del programa): 4250 mm

- Vía de rodillos (elemento de 10 vías): 1 pieza

- Vía de rodillos (elemento 2 vías): 5 piezas

- Pinzas de sujeción: 7 piezas (las 3 primeras de dos dedos, todas las demás de un dedo)

Más información

Máquina aún en marcha

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos