Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

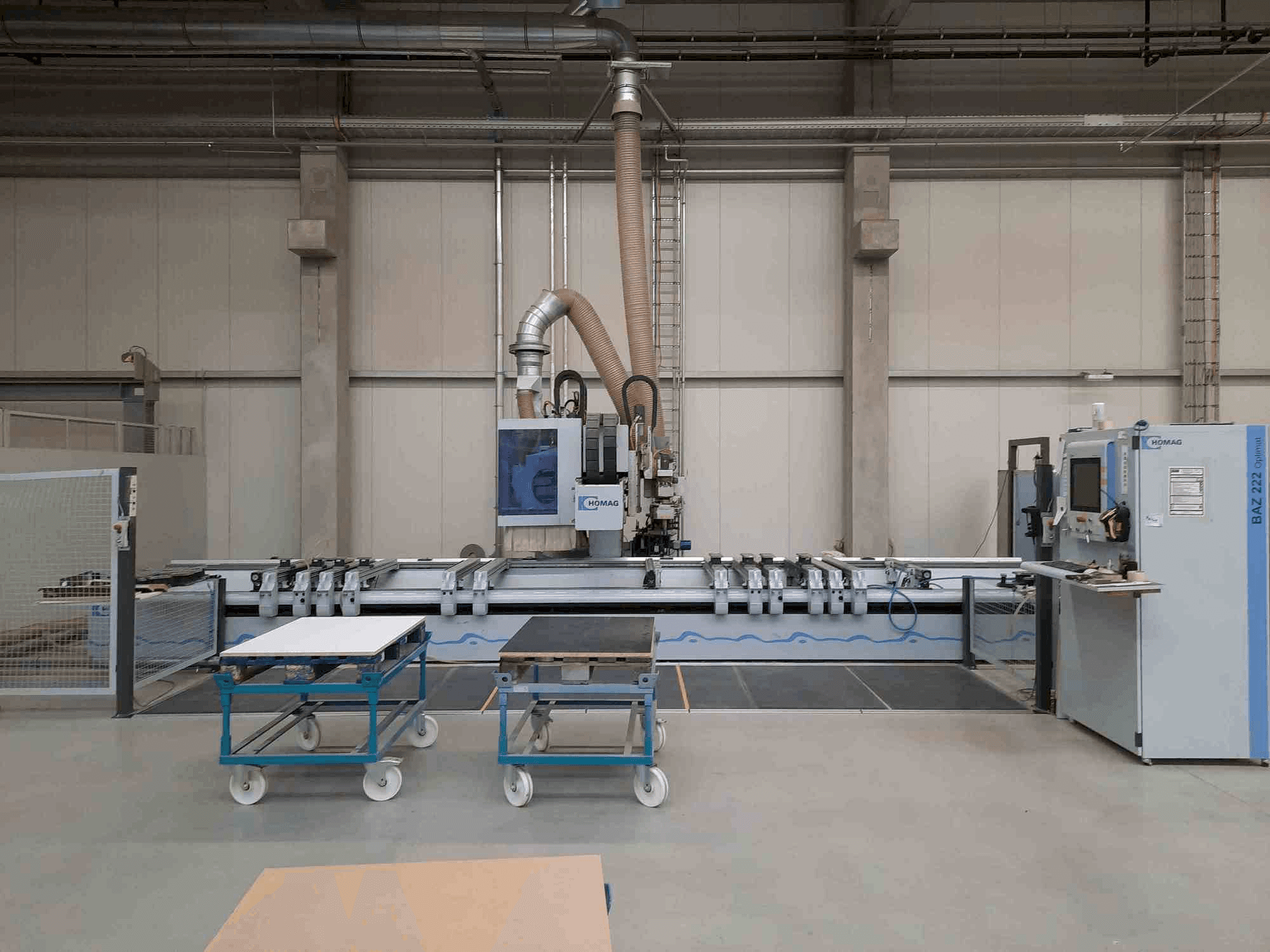

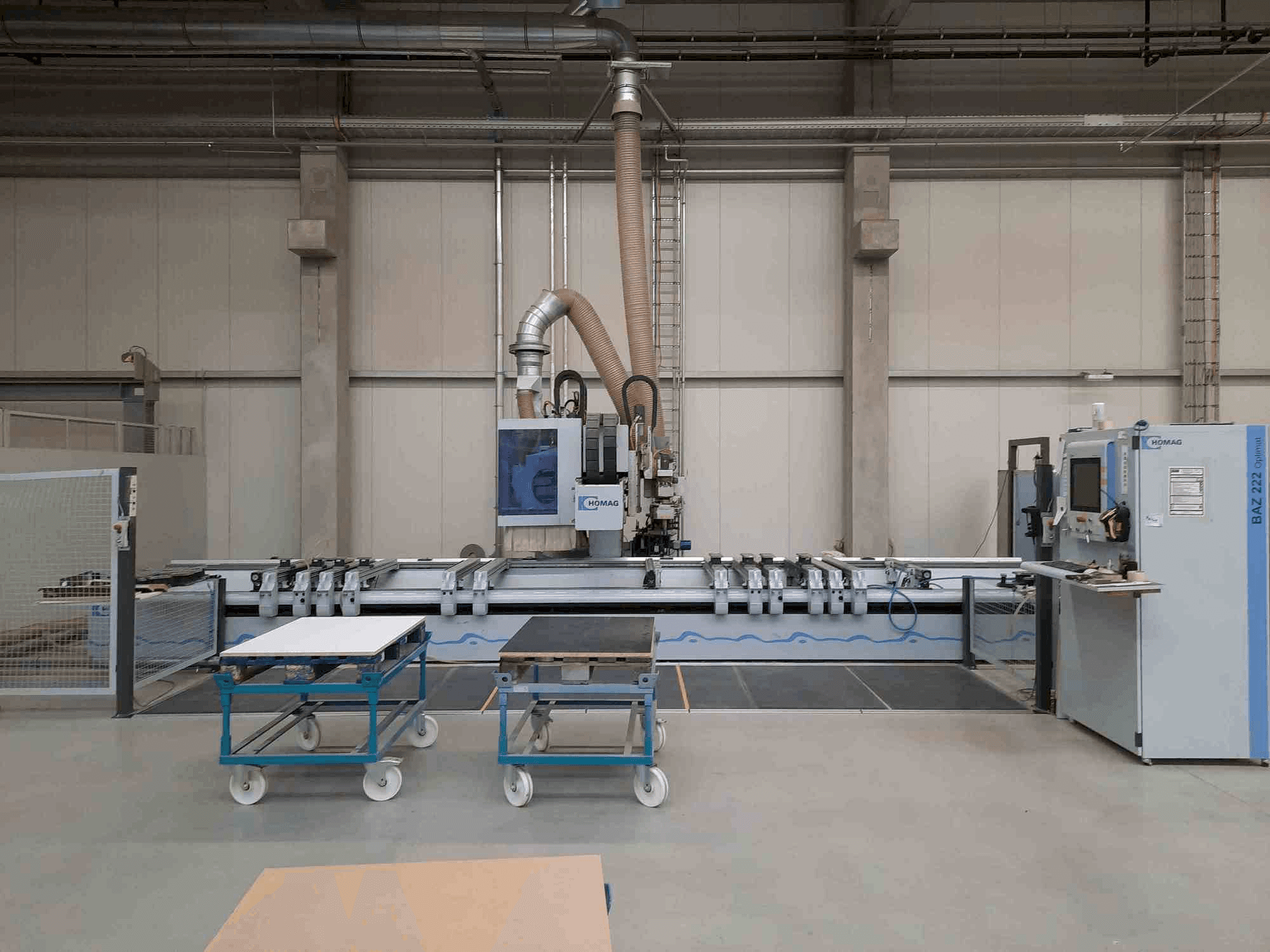

HOMAG - OPTIMAT BAZ222/60/KDE-WOO-HOM-2010-00002

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para madera

- ➤ HOMAG OPTIMAT BAZ222/60/K Usada - Venta

Este centro de procesamiento CNC se fabricó en 2010. Cuenta con un husillo principal de 15 KW con HSK F63, un cambiador de placas de 18 pliegues y un cabezal de taladrado de 30 husillos. Equipado con una unidad de encolado POWER EDGE para un encolado de cantos preciso y una unidad FLEX-5 para una mayor versatilidad. Ideal para manipular piezas grandes con un grosor máximo de 300 mm. Si desea más información sobre este centro de mecanizado de madera, póngase en contacto con nosotros.

Resumen

- marca: HOMAG

- año: 2010

- MODELO: OPTIMAT BAZ222/60/K

- tipo de aplicación: Mecanizado CNC

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado CNC

Información adicional

Equipamiento adicional

- Unidad de encolado con unidad FLEX-5

- Husillo principal 15 KW, HSK F63

- Eje C con interfaz de unidad

- Cambiador de placas 18 pliegues D=130

- Cabezal de perforación 30 husillos: V20 / H10/ S360° "MPU"

- Sierra de ranurar: Ø de la hoja: 200 mm

- Husillo de fresado adaptable 6 KW para cabezal de taladrado

- Unidad de encolado POWER EDGE para encolado a 360° con junta a tope

- Unidad de fresado a ras para cambiador de herramientas

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Precisión en el mecanizado con control cnc avanzado, que garantiza acabados de alta calidad

- Flexibilidad en la manipulación de piezas de distintos tamaños y operaciones complejas con la unidad flex-5 y el sistema de encolado de cantos motorizado

Ventajas técnicas de la máquina

- Unidad combinada de fresado y raspado de 100 mm de ancho

- Unidad combinada de recorte y copiado, trazada

- Unidad de fresado de encastre 2 husillos d=16/20

- Cinta transportadora de virutas para b200/52-72

- Consola de soporte led-setup 1300-1600 mm

- Capacidades de procesamiento versátiles que incluyen fresado, taladrado, encolado y encolado de cantos

- El husillo principal de alta potencia y el husillo de fresado adaptable mejoran la eficacia del mecanizado

- Amplias opciones de utillaje con un cambiador de placas de 18 pliegues y unidades especializadas para tareas específicas

Más información

Dimensiones de la pieza:Longitud máx: Todas las unidades: campo simple 6.000 mm, proceso pendular 2.375 mm. Anchura máx: Frontal todas las unidades 1150mm, en fresado con herramienta-diam. 25 mm: 1220mm, en canteado: 1220mm. Espesor máx: 300 mm (incluido mandril en uso como fresadora superior), hasta máx. 60 mm con sujeción estándar. Capacidad de manipulación de material de canto con una altura de 105 mm para la unidad de encolado BAZ222/322, permitiendo el canteado de piezas de trabajo de hasta 100 mm de grosor.

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos