Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

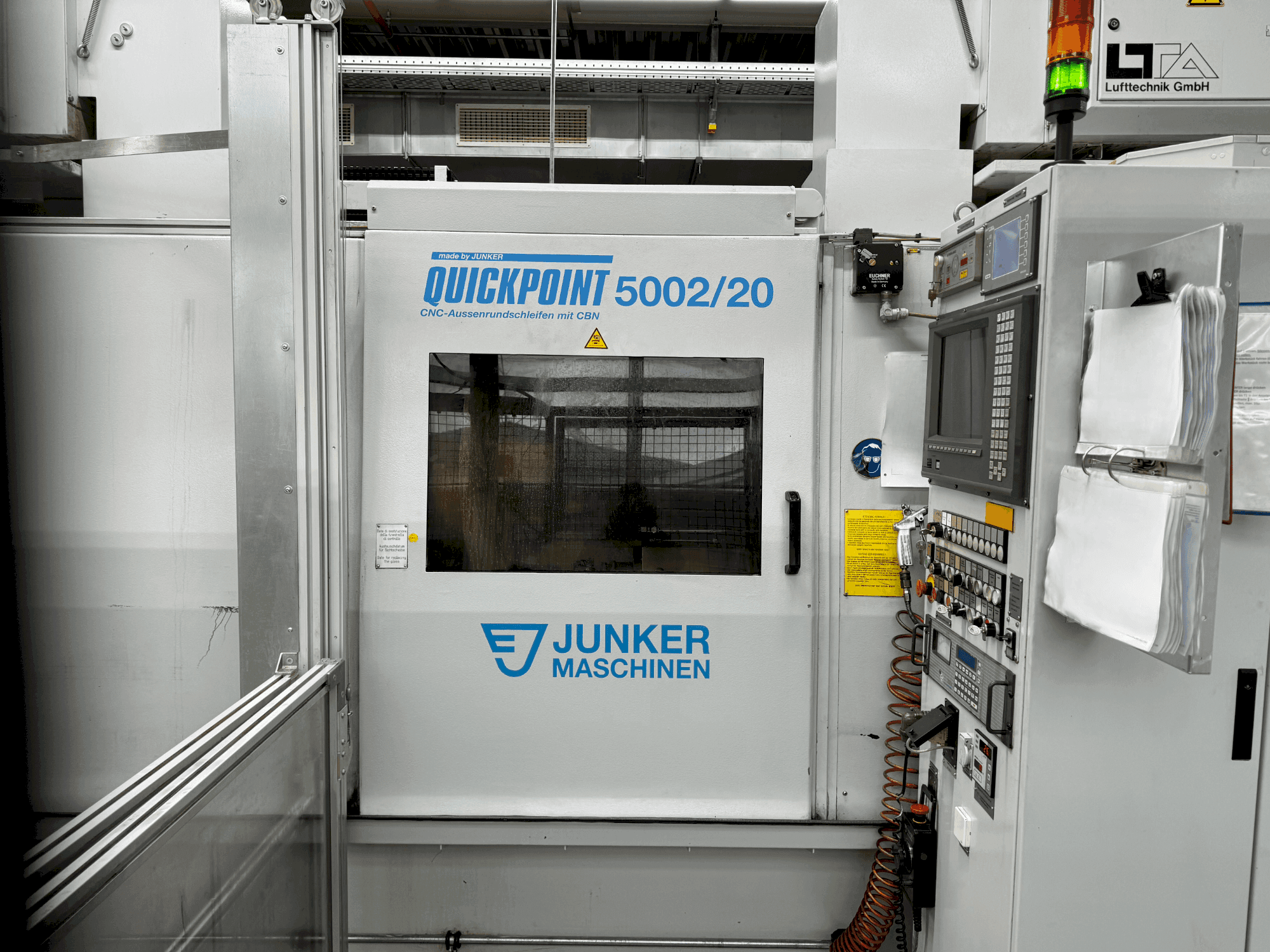

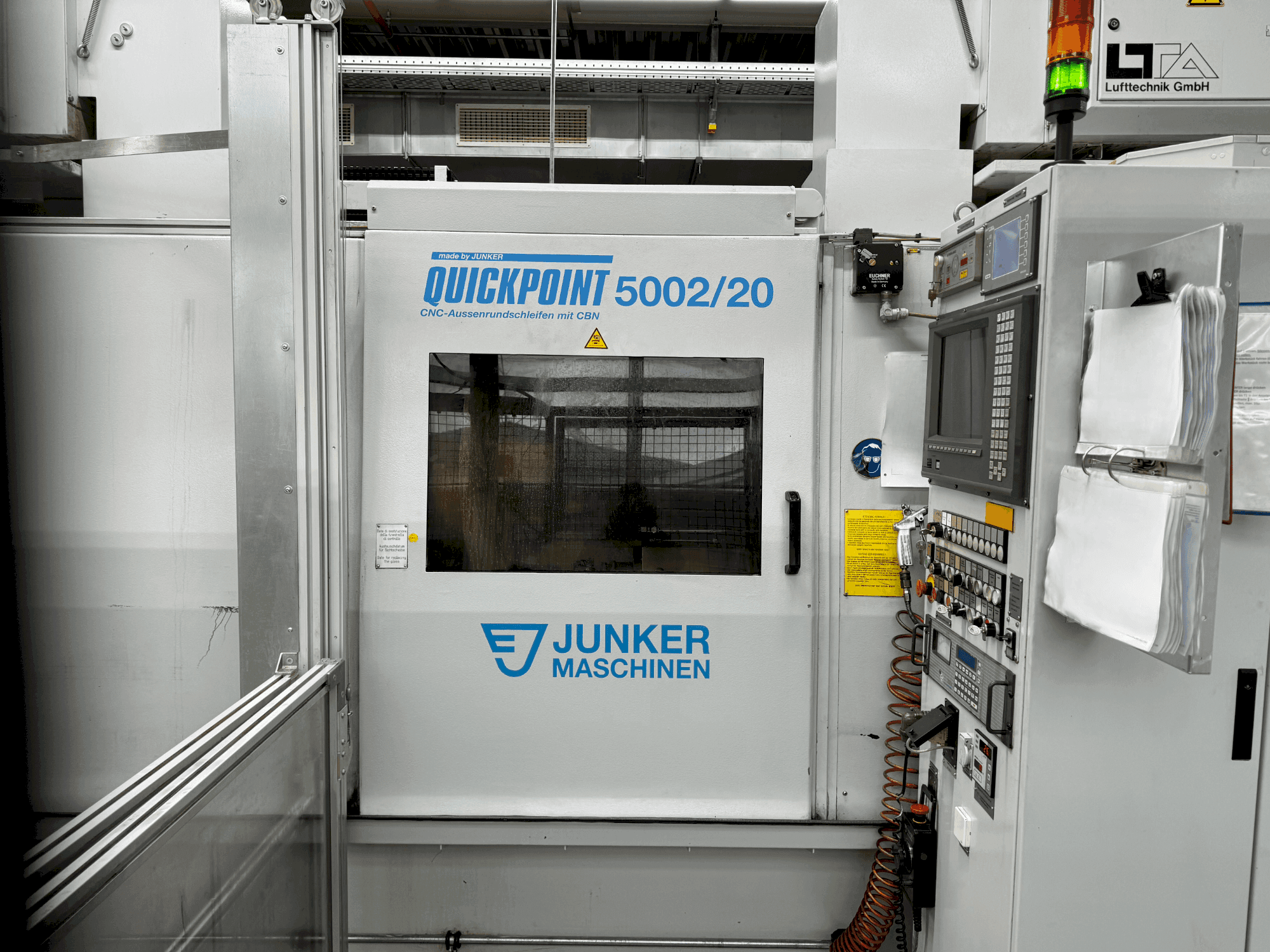

JUNKER - Quickpoint 5002/20DE-GRI-JUN-2000-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- Rectificadora cilíndrica JUNKER Quickpoint 5002/20

Esta rectificadora cilíndrica JUNKER Quickpoint 5002/20 fue fabricada en el año 2000 en Alemania. Tiene un diámetro de rectificado de 280 mm y una longitud de rectificado de 900 mm. Equipada con un eje Z de 900 mm de recorrido, puede manejar un peso máximo de pieza de trabajo de 30 kg. Como unidad de control tiene un control FANUC 15-TB. Se suministra con 2 unidades de extracción (fabricadas por LTA) y un sistema de filtro de aceite (de fabricación propia). La máquina se utiliza actualmente como parte de una línea de robots y se venderá debido a la sustitución por una nueva máquina. Ver galería de fotos y videos para más impresiones.

Resumen

- marca: JUNKER

- año: 2000

- MODELO: Quickpoint 5002/20

- tipo de aplicación: Rectificado

- Ubicación: Alemania

- tipo de máquina: Rectificadora Cilíndrica

- Marca de unidad de control: FANUC

Información técnica - JUNKER Quickpoint 5002/20

Unidad de Control

- Marca del control: FANUC

- Modelo del control: 15-TB

Dimensiones

- Profundidad de la máquina: 5000 mm

- Altura de la máquina: 2500 mm

- Peso de la máquina: 15000 kg

Recorrido

- Número de ejes: 3

- Recorrido eje Z: 900 mm

Especificación Técnica

- Max. Workpiece Diameter: 250 mm

Información adicional

Equipamiento adicional

- 2x unidades de extracción (fabricadas por LTA)

- Sistema de filtro de aceite en gran parte autoconstruido en bandeja colectora, sistema con separador magnético (probablemente sólo reutilizable condicionalmente, pero actualmente funcional), actualmente construido en un diseño de división en frío con refrigerador interno y condensador externo.

- Las muelas de recambio pueden entregarse si aún están disponibles en el momento del desmontaje.

- También habrá disponibles y podrán regalarse otros accesorios, como puntas, sistemas de controladores, sondas de medición, etc.

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Máquina siempre muy bien mantenida

- Línea de producción sólida y fiable

- Las máquinas quickpoint pueden utilizarse para una amplia gama de aplicaciones y, al mismo tiempo, ofrecen una productividad impresionante.

- Versatilidad y excelente calidad de las piezas

- 3 ejes (x, z y b)

Ventajas técnicas de la máquina

- Sistema de carga: manual

- Cabezal: fijo

- Husillo portapiezas // dimensión: 100 x 400 mm, lubricación permanente por grasa, protección de rodamientos por aire comprimido, accionamiento por servomotores (eje c), cono y fijación especial mk4 o junker collar estándar ⌀ 75mm

- Contrapunto // manualmente mediante rueda de cadena, presión de sujeción ajustable hidráulicamente

- Manguito del contrapunto // ⌀ 100 x 430 mm, mk 4 resp. Collar estándar junker ⌀ 75 mm

- Mesa de rectificado // eje z (controlado por cnc)

- Cabezal // entrada: eje x (controlado por cnc), horizontal: -6° a + 15°, eje b (controlado por cnc), vertical: -0. 5°, 0° y +0. 5° (giratorio op)

- Husillo rectificador // ⌀ 180 x 400 mm, brida: ⌀ 190 mm, collar estándar: ⌀ 127 mm, potencia motriz: 24 kw.

- Muela abrasiva // borazón (cbn) o diamante, diámetro: ⌀ 400 mm, diámetro interior: ⌀ 127 mm, ancho de recubrimiento: 5 mm.

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos