Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

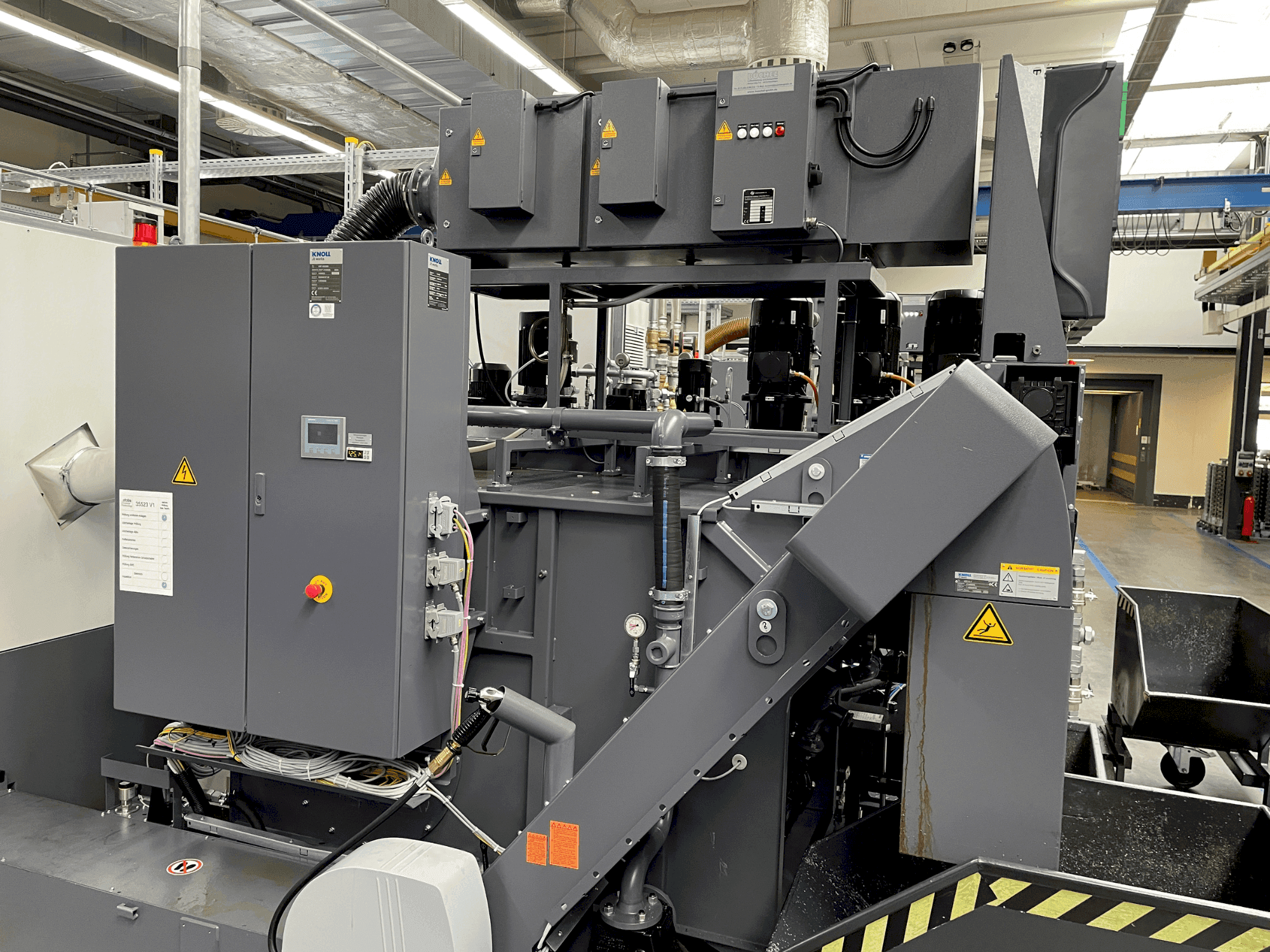

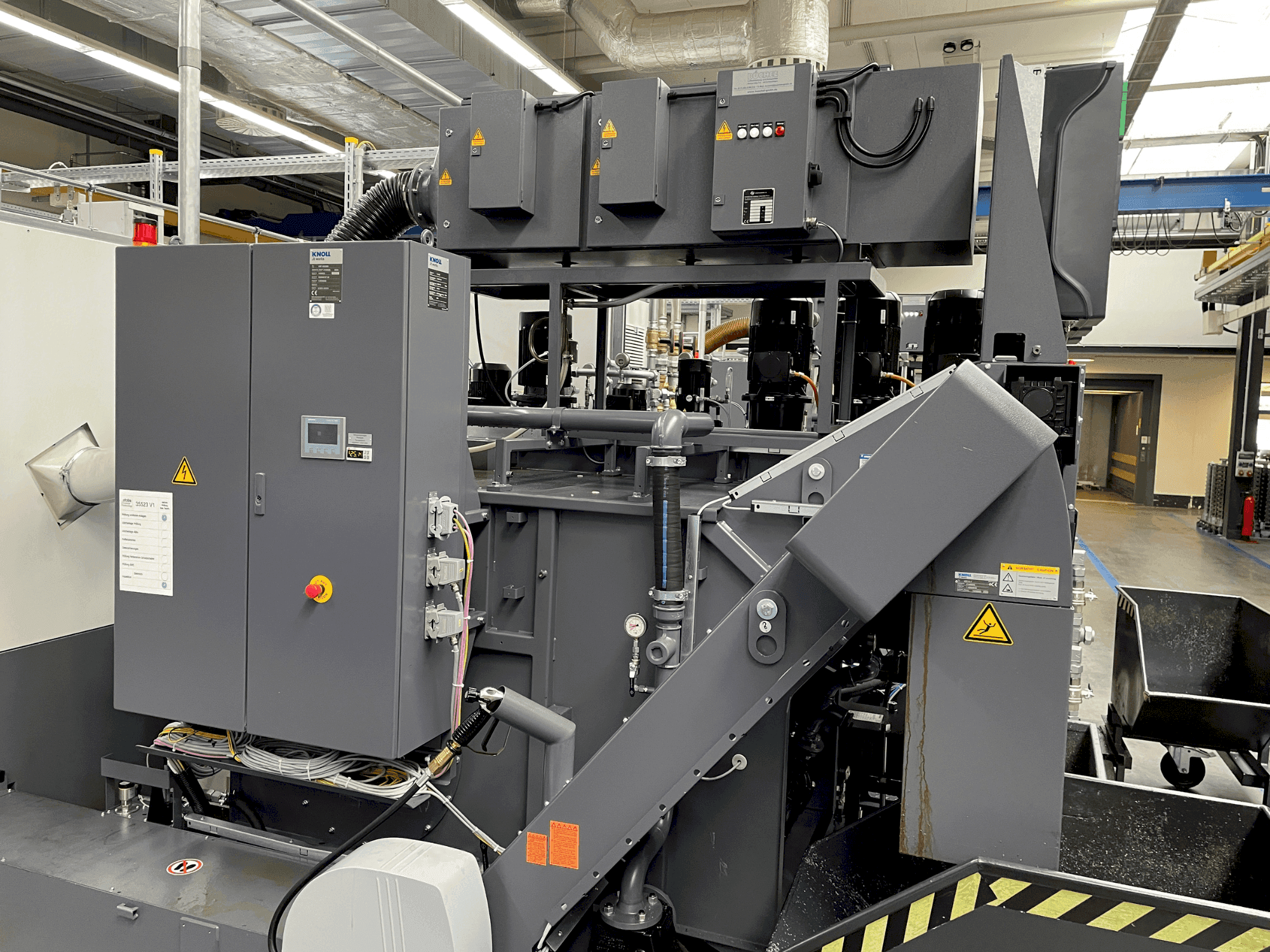

KNOLL - KF 400/3400DE-OTH-KNO-2019-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ KNOLL KF 400/3400 Usadas - 2019 - Venta | gindumac.com

Esta KNOLL KF 400/3400 se fabricó en 2019. Cuenta con un transportador de cinta rascadora y un sistema de filtrado compacto diseñado para procesos de mecanizado con condiciones ambientales específicas. El sistema incluye un tanque limpio con una capacidad de 3400 litros y una variedad de bombas, incluida una bomba de proceso centrífuga y una bomba de tornillo, que garantizan un movimiento eficiente del fluido. Ideal para la manipulación de emulsiones lubricantes refrigerantes, también incluye intercambiadores de calor de placas para una refrigeración eficaz. Póngase en contacto con nosotros para obtener más información.

Resumen

- marca: KNOLL

- año: 2019

- MODELO: KF 400/3400

- tipo de aplicación: Otras máquinas herramienta

- Ubicación: Alemania

- tipo de máquina: Máquina herramienta

Información adicional

Equipamiento adicional

- Cinta transportadora rascadora tipo 400 K-1, emulsión media.

- Sistema de filtro compacto KF tipo KF400/3400.

- Filtro compacto KF 400 con posición de accionamiento/entrada KF derecha, unidad de recogida KF sí, soporte de vellón KF en la parte trasera (montado externamente).

- Tanque limpio, plano, forma rectangular, dimensiones 2500x1500x1100mm, capacidad 3400l, material acero, espesor chapa 3mm, tapa tanque chapa acero.

- Bomba centrífuga, función de bomba de proceso, caudal 320l/min, presión 5 bar, versión sumergible.

- Bomba de tornillo KTS 32: casquillo de pistón HD (KB), paso de husillo 48, termistor PTC y control por frecuencia, caudal 65 l/min y presión 80 bar.

- Intercambiador de placas 25 placas: dimensiones 424x323x670mm, medio a refrigerar, potencia frigorífica 40 kW.

- Intercambiador de calor de placas 15 placas: material de las placas 1.4404, potencia frigorífica 16 kW.

- Bomba de circulación y alimentación PHE: caudal 50 litros/min, presión 5,5 bar.

- Sistema de lubricante refrigerante para emulsiones

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Construcción robusta, sistemas de filtración avanzados.

Ventajas técnicas de la máquina

- Sistema integral diseñado para soportar diversos procesos de mecanizado con funciones integradas de refrigeración y filtración.

- Las bombas de alta presión y alto caudal garantizan una gestión eficaz de la refrigeración y la lubricación durante las operaciones.

- El sistema se utilizó para filtrar virutas de latón, y el nivel de pureza depende del tipo de vellón filtrante utilizado.

Más información

Máquina aún en marcha

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos