Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

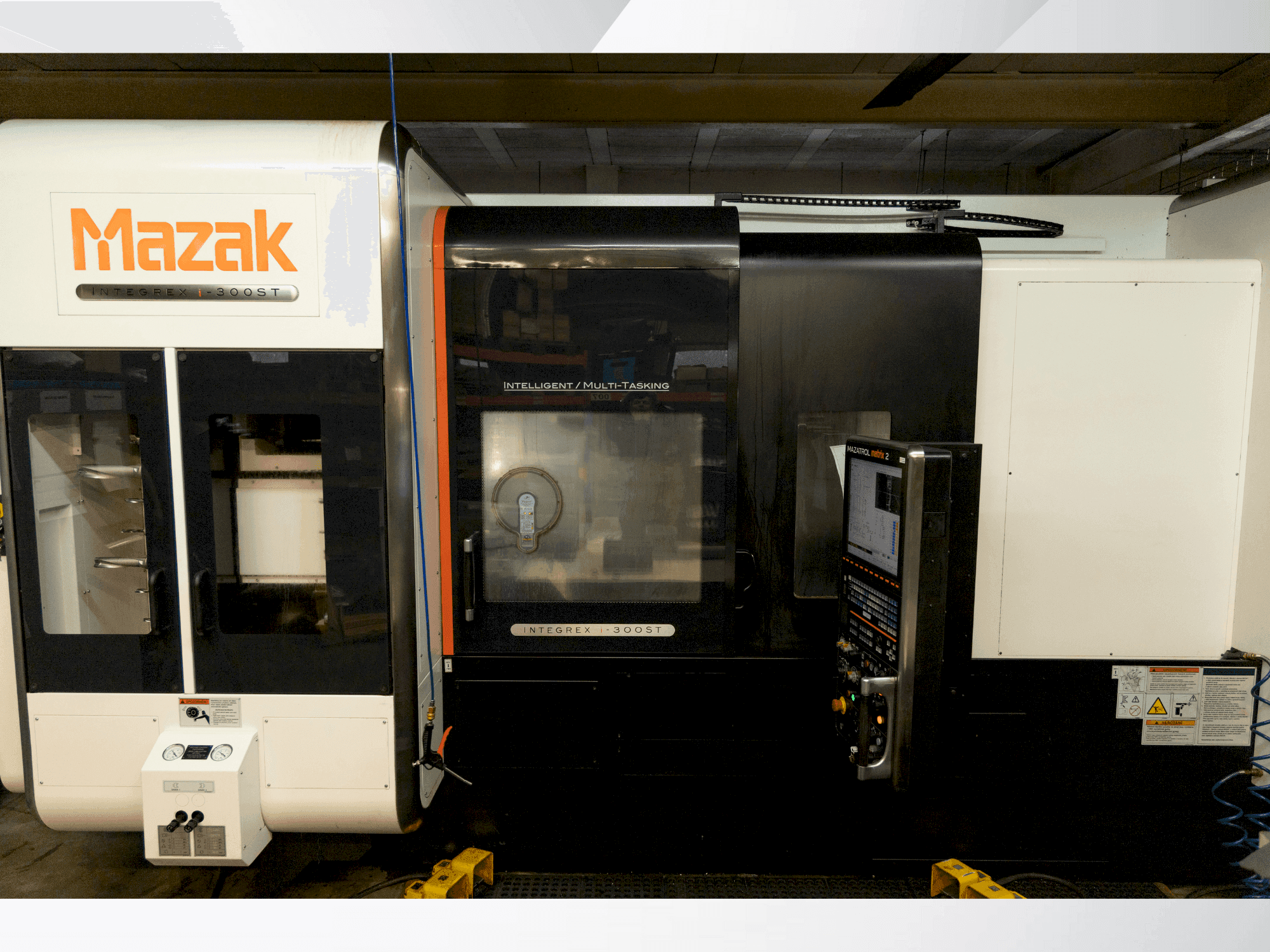

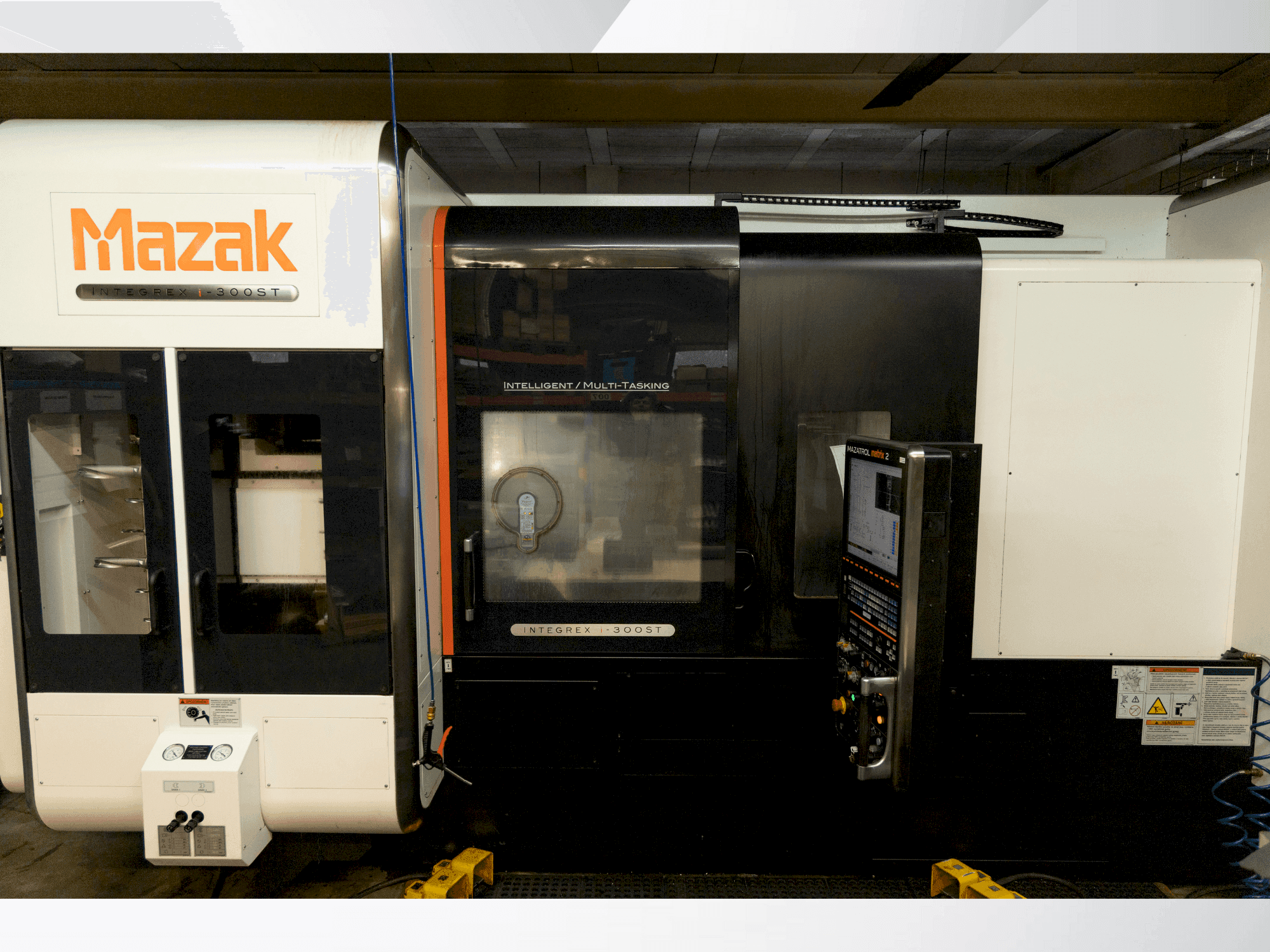

Mazak - Integrex i-300ST-1500UCZ-TUR-MAZ-2012-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Torno usado Mazak Integrex i-300ST-1500U | En venta

Este torno Mazak Integrex i-300ST-1500U de 7 ejes se fabricó en 2012. Cuenta con un paso de barra del husillo principal de 80 mm, un cambiador de herramientas con capacidad para 72 herramientas y una velocidad del husillo de fresado de 12.000 rpm. Otras características destacadas son un sistema de refrigeración de alta presión a 14 bares, un transportador de virutas y una unidad de filtro de niebla. Ideal para la producción de prototipos, la máquina incluye herramientas, mandriles y mordazas. Si desea más información sobre este torno, póngase en contacto con nosotros.

Resumen

- marca: Mazak

- año: 2012

- MODELO: Integrex i-300ST-1500U

- tipo de aplicación: Torneado

- Ubicación: República Checa

- tipo de máquina: Centro de torneado y fresado

Información técnica - Mazak Integrex i-300ST-1500U

Recorrido

- Número de ejes: 7

- Recorrido eje X: 615 mm

- Recorrido eje Y: 250 mm

- Recorrido eje Z: 1585 mm

Especificación Técnica

- Número de herramientas: 72

- Velocidad del husillo: 4000 RPM

Información adicional

Equipamiento adicional

- Filtro de niebla

- Refrigeración a alta presión (14 bar)

- Limpieza por aclarado del espacio de trabajo (2,7 bar/60 l)

- RMP600-Radio/Sonda de radio

- Preparación para la refrigeración de 70 bar a través del husillo

- Detector de sobrecarga programable

- Eje C en el segundo husillo

- MO321 - Fresado de engranajes sin herramienta

- TE810 - Preparación para herramientas Multi y Flash

- NO117 - Control de filo de herramienta para 5 ejes continuos / Movimientos de ejes: X / Y / Z / X2 / Z2 615 / 250 / 1585 / 230 / 1388 mm / W 1539 mm / Indexación del eje C 0.0001°.

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Equipamiento completo para diversas operaciones de mecanizado (torneado, fresado, taladrado, roscado, etc. )

- Utilizado exclusivamente con los técnicos de servicio de mazak

- Torreta inferior número de herramientas 9

Ventajas técnicas de la máquina

- Paso de la barra del husillo principal 80 mm

- Velocidad del cabezal de fresado (eje b): 12. 000rpm

- No123 - corrección del radio de la herramienta para el control continuo de 5 ejes

- Nº137 - compensación dinámica eia i

- No092 - roscado síncrono para herramienta accionada

- Control continuo de 5 ejes eia/iso

- Gran capacidad de herramientas con cargador de 72 herramientas (portaherramientas hsk-63)

- Control continuo avanzado de 5 ejes con diversas funciones de compensación y corrección

- Máx. Diámetro de mecanizado 658 mm / máx. Longitud de mecanizado 1519 mm / máx. Peso de la pieza 450 (1er husillo) / 400 (2º husillo) kg

- Potencia del motor del husillo principal 30 (30 min. ) / 22 (continua) kw / potencia del motor del subhusillo 26 (30 min. ) / 22 (continua) kw /

Más información

Máquina aún en marcha

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos