Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

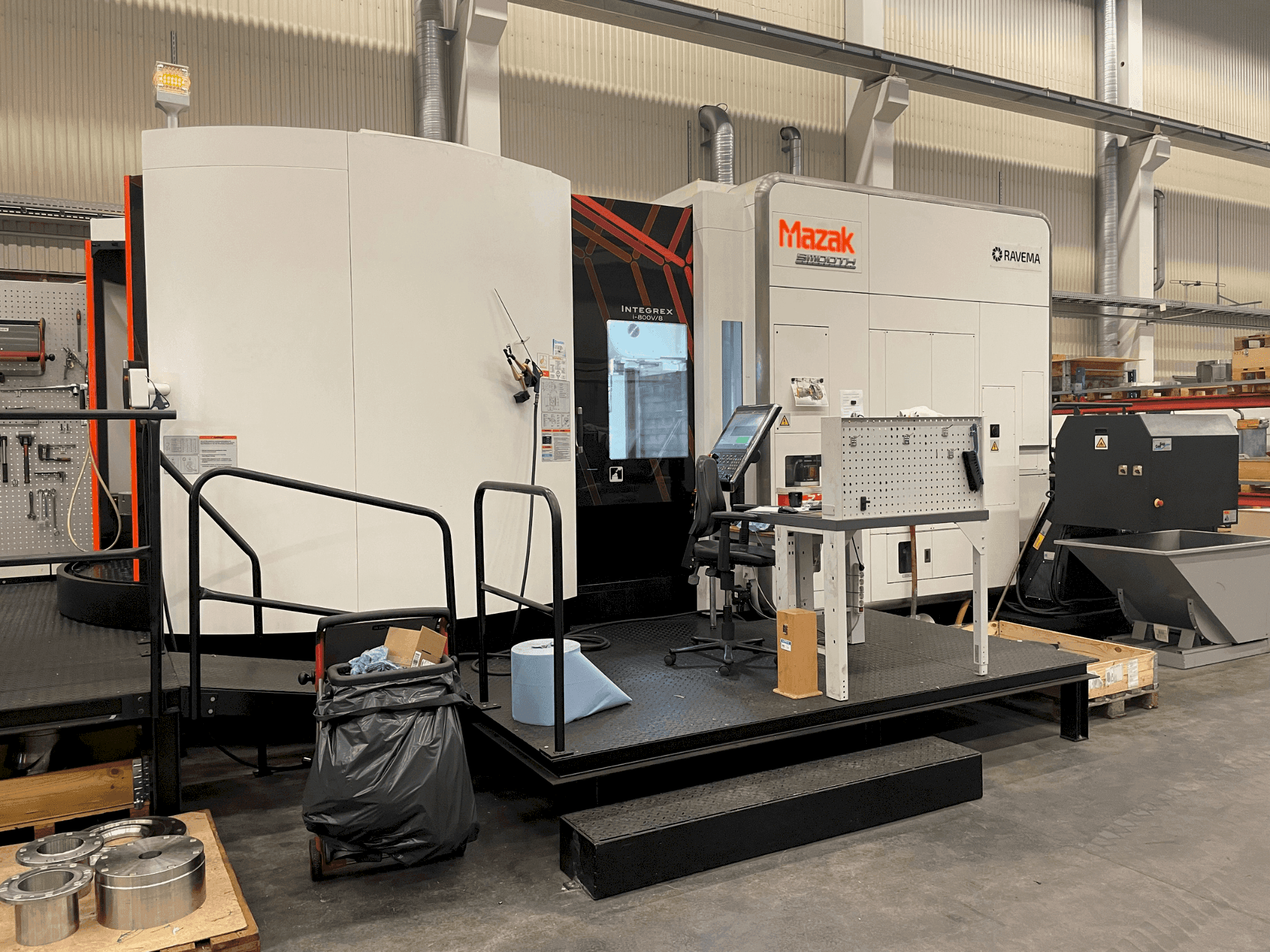

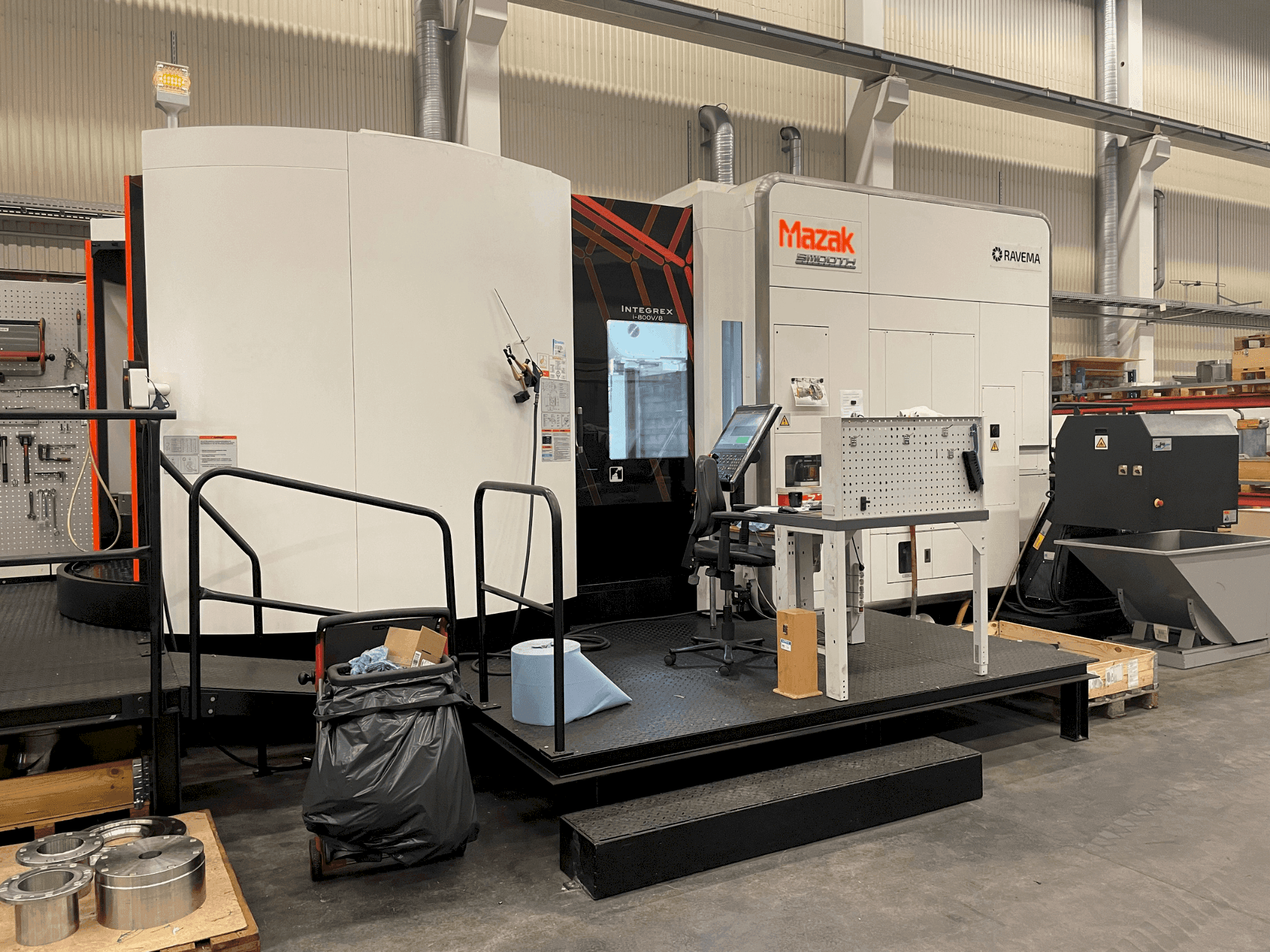

Mazak - INTEGREX i-800V/8SE-MIL-MAZ-2017-00002

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- Centro de mecanizado universal de 5 ejes MAZAK INTEGREX i-800V/8 (2017)

Este centro de mecanizado universal (torno-fresadora) de 5 ejes MAZAK INTEGREX i-800V/8 (2017) se fabricó en 2017 en Japón. Está equipado con un husillo de fresado de alto par con retroalimentación de escala (máx. 5.000 rpm), un almacén de herramientas 80x (capto), sistema de identificación de herramientas MAZAK y función multiherramienta. La máquina dispone de un paquete de mecanizado de 5 ejes para SmoothX (carrera del eje X: 1.700mm / Carrera eje Y: 1.500mm / Carrera eje Z: 1.150mm / Eje B: 150° (-30°, +120°) / Eje C: 360°), funciona con un diámetro máximo de mecanizado de 1.500 mm y una velocidad de la mesa de 500 rpm. Está equipada con una sonda RMP 600 de RENISHAW, medición láser de la herramienta, sistema de control de la temperatura del refrigerante, soplado de aire a través del refrigerante, opción de refrigerante de gran volumen y transportador de virutas (parte trasera, derecha). El tiempo de corte es de 3539 horas. Esta máquina multitarea INTEGREX i-800V/8 combina fresado completo en 5 ejes y potentes operaciones de torneado para procesar de forma productiva piezas grandes y muy complejas, como componentes de motores a reacción y corona dentada cónica en espiral. Como la máquina sigue funcionando, puede inspeccionarse en cualquier momento. Vea la galería de vídeos para obtener más impresiones.

Resumen

- marca: Mazak

- año: 2017

- MODELO: INTEGREX i-800V/8

- horas de producción: 3539

- tipo de aplicación: Fresado

- Ubicación: Suecia

- tipo de máquina: Centro de mecanizado universal

Información técnica - Mazak INTEGREX i-800V/8

Recorrido

- Eje B máximo: 150°

- Eje B mínimo: -30°

- Eje C: 360°

- Número de ejes: 5

Especificación Técnica

- Número de herramientas: 80

- Velocidad del husillo: 5000 RPM

Información adicional

Equipamiento adicional

- Renishaw RMP 600

- Transportador de virutas (trasero/derecho)

- Superflow V30C-J

- Extractor GP3000

- Medición de herramientas láser

- Sistema de control de la temperatura del refrigerante

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Refrigerante de gran volumen

- Engranaje suave

- Ciclo de vaciado de chips // hilos sincronizados

- Compensación de radio // funcionamiento tipo tupí

- Adaptador mt connect // g00 constante de pendiente

- Paquete de mecanizado de 5 ejes para smoothx orbitturn

- Molino de engranajes lisos

- Compensación de la longitud de la herramienta en la dirección del eje de la herramienta

- Fresado de engranajes

- Función de cuadro de mando energético

Ventajas técnicas de la máquina

- 5 ejes: recorrido eje x 1. 700mm, recorrido eje y 1. 500mm, recorrido eje z 1. 150mm, eje b 150° (-30°, +120°), eje c 360°.

- Soplado de aire a través del husillo

- Función multiherramienta

- Almacén para 80 herramientas, capto

- Sistema de identificación de herramientas mazak

- Coordenadas cilíndricas y polares

- Husillo de fresado de alto par con retroalimentación de escala, máx. 5. 000 rpm

- Máx. Diámetro de mecanizado: 1. 500mm

- Velocidad de la mesa: 500 rpm

- Prep. Para renishaw sprint

Más información

Luz de estado de la máquina de 3 colores // MAZAK API // Tiempo total de la máquina 18501 h, Tiempo de corte 3539 h

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos