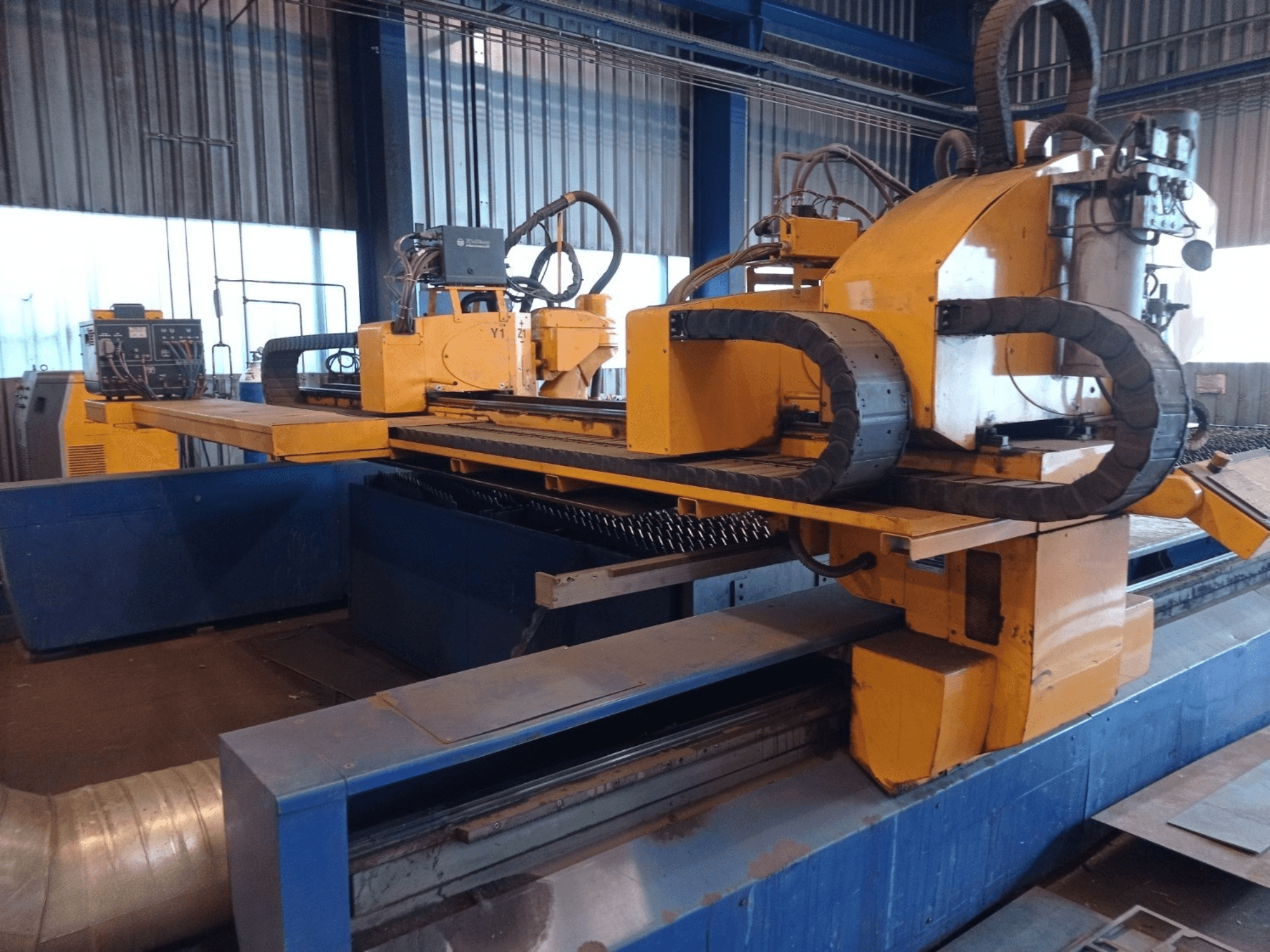

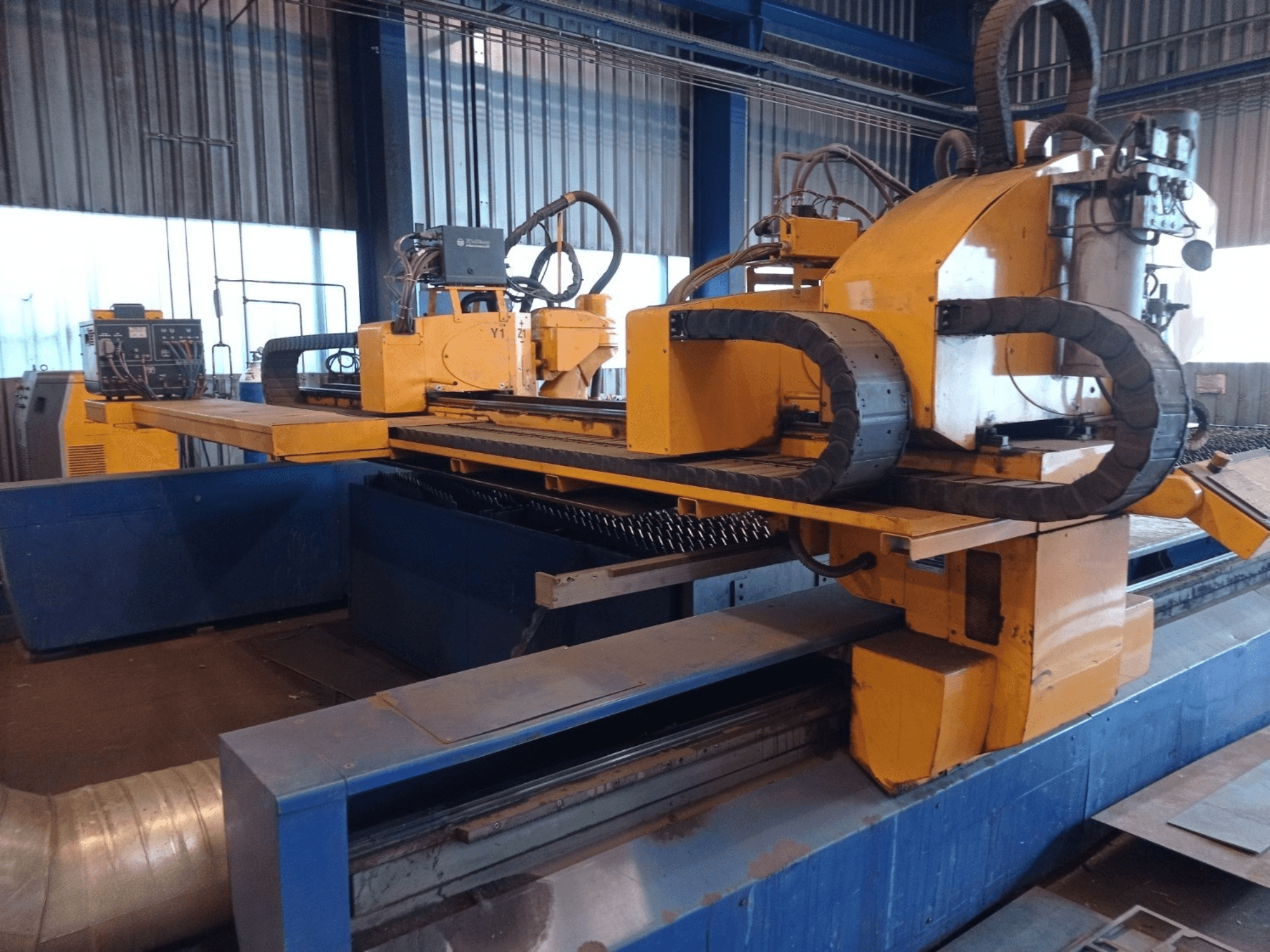

MicroStep - MG 6001.25PrGBHU-CUT-MIC-2011-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para chapa

- ➤ MicroStep EasyCut 6001.25PrGB usado | Cortadora de plasma

Esta MicroStep EasyCut 6001.25PrGB se fabricó en 2011. Se trata de una máquina de corte por plasma/oxi-combustible CNC diseñada para aplicaciones industriales pesadas. Entre sus características se incluyen una gran área de trabajo de 6000 × 2500 mm, un pórtico accionado por dos lados y compatibilidad con software CAM como mCAM y AsperWin. Admite hasta 6 antorchas de oxicorte y ofrece opciones como el control automático de altura. Nota: la consola de gas es defectuosa. Póngase en contacto con nosotros para obtener más información sobre esta máquina.

Resumen

- marca: MicroStep

- año: 2011

- MODELO: MG 6001.25PrGB

- tipo de aplicación: Corte

- Ubicación: Hungría

- tipo de máquina: Cortadora plasma

Información adicional

Estado: Fuera de uso durante un tiempo; consola de gas/mezclador de gas defectuosos (tipo Kjellberg, último informe del técnico de servicio).

Área de trabajo 6000 × 2500 mm

Tecnologías de corte: Plasma y/u oxicorte (combinables)

Espesor máximo del material:

Oxicorte: hasta 300 mm

Plasma: aprox. 35-60 mm (dependiendo de la fuente de energía, por ejemplo, Hypertherm HPR)

Control: Control CNC MicroStep iMSNC o CyberFab; compatible con mCAM y AsperWin

Temperatura de funcionamiento: -10 °C a +45 °C

Capacidad para varias antorchas: Posibilidad de hasta 2-6 antorchas de oxicorte

Estructura de la máquina: Pórtico accionado por dos lados para mayor precisión y repetibilidad

Observaciones: La máquina no funciona desde hace mucho tiempo; se ha detectado un fallo en la consola de gas (tipo Kjellberg)

Equipamiento adicional

Fuente de energía de plasma (por ejemplo, Hypertherm HPR): determina la capacidad de corte por plasma

Equipo de oxicorte: cabezales/antorchas de oxicorte (hasta 2-6 posibles)

Cabezal de corte por plasma

Control automático de la altura de la antorcha

Módulos de software: mCAM (CAM para preparación de la producción), AsperWin (anidado automático)

Integración del sistema de producción (PPS)

Consola de gas/mezclador de gas (tipo Kjellberg; actualmente defectuoso)

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos