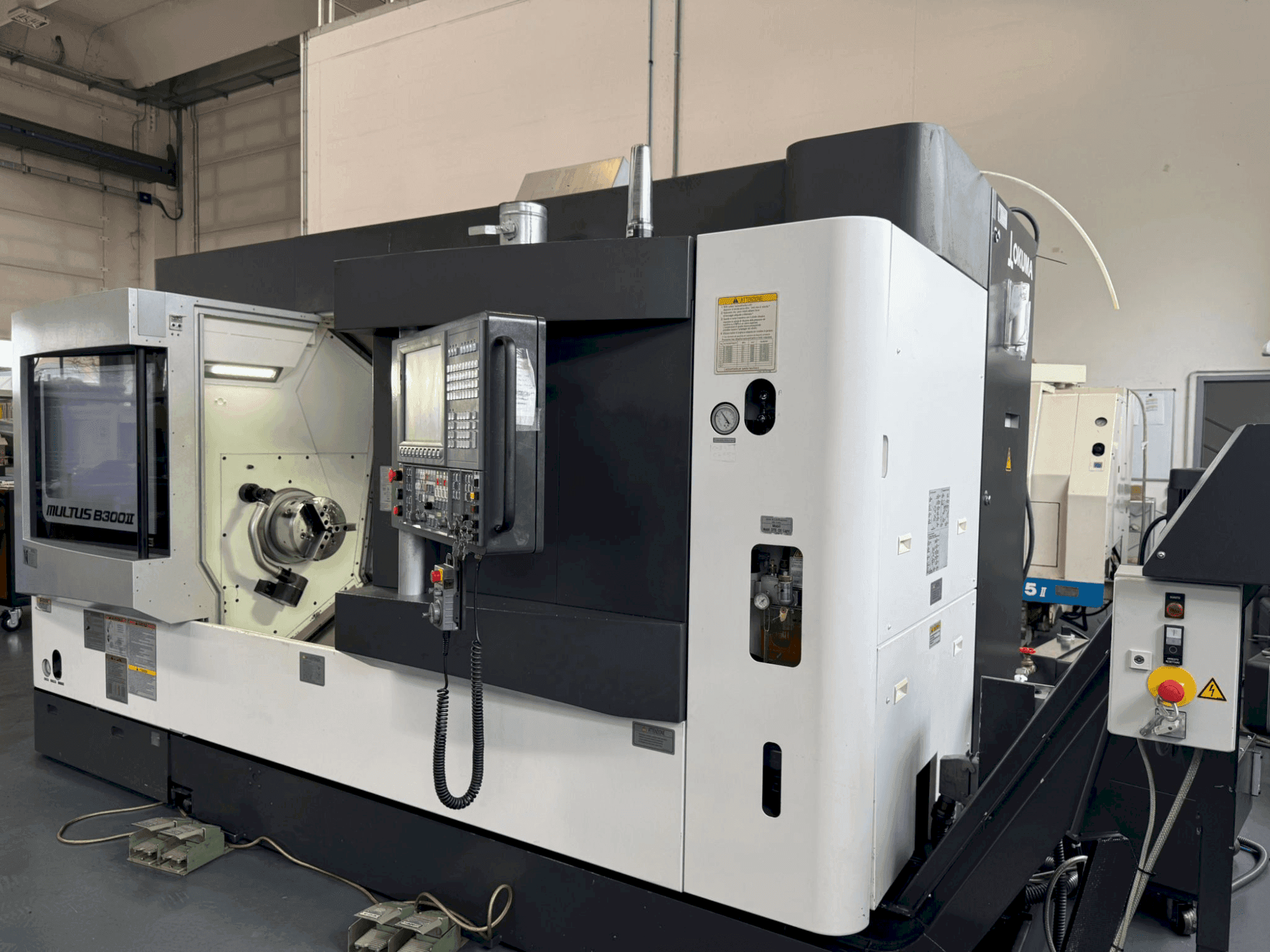

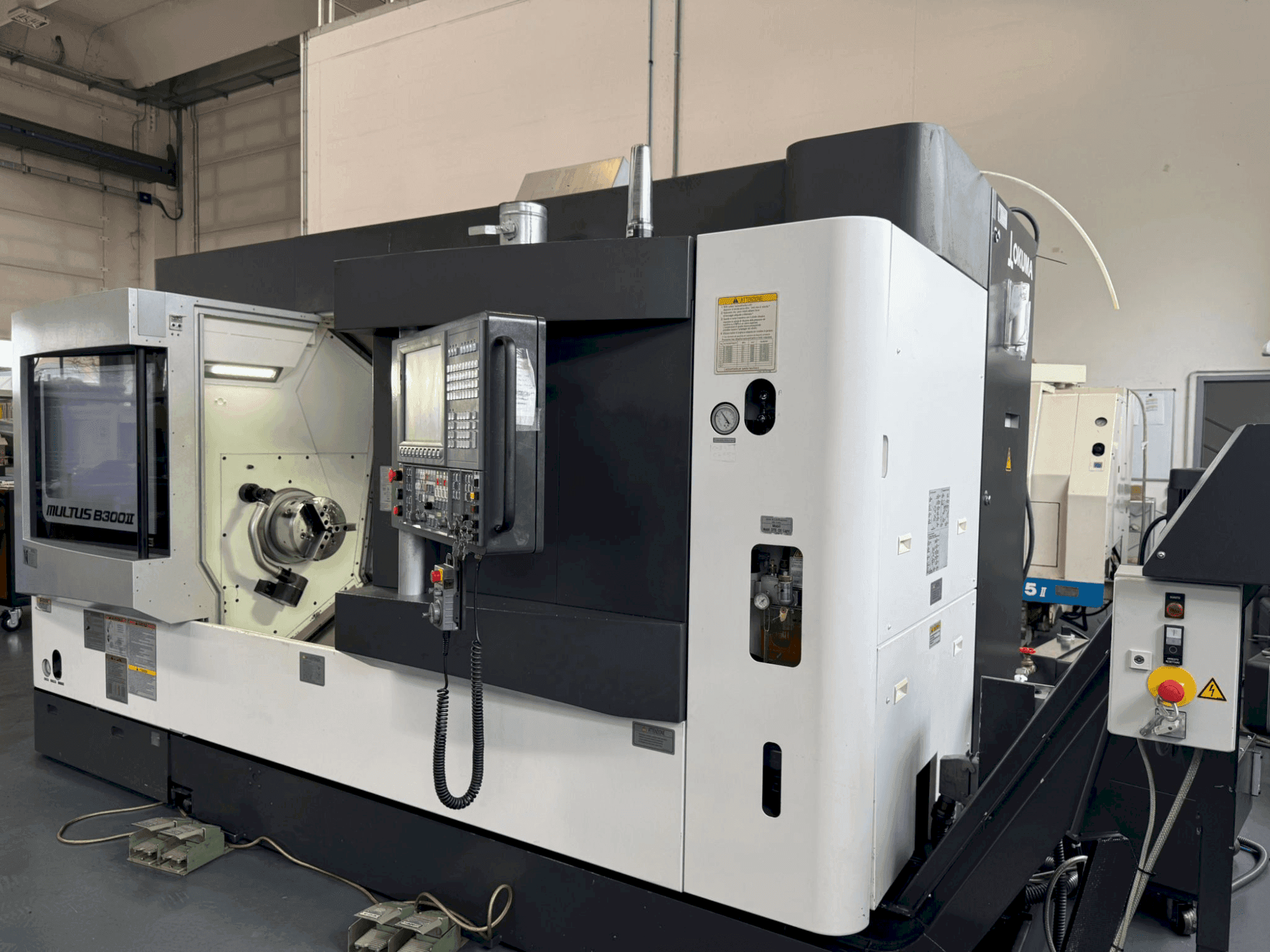

Okuma - MULTUS B300IIIT-TUR-OKU-2016-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Venta de Okuma MULTUS B300II usados | gindumac.com

Esta OKUMA MULTUS B300 II W de 5 ejes se fabricó en 2016. Cuenta con un husillo ASA 8 que ofrece 5.000 rpm y una capacidad de 65 mm bar, capaz de manejar un diámetro de torneado máximo de 630 mm. Incluye una preparación de refrigerante de alta presión de 70 bar, un eje B continuo con HSK63 y un almacén de herramientas con 60 posiciones, optimizando tanto las capacidades de torneado como de fresado. Si busca operaciones de torneado-fresado de alta calidad, considere esta máquina OKUMA. Contacte con nosotros para más información sobre esta máquina.

Resumen

- marca: Okuma

- año: 2016

- MODELO: MULTUS B300II

- tipo de aplicación: Torneado

- Ubicación: Italia

- tipo de máquina: Centro de torneado y fresado

- Marca de unidad de control: OKUMA

Información técnica - Okuma MULTUS B300II

Unidad de Control

- Marca del control: OKUMA

- Modelo del control: OSP-P300S-H

Recorrido

- Recorrido eje Y: 160 mm

Información adicional

Equipamiento adicional

- 60 herramientas ATC / Preparación de refrigerante a alta presión: 70 bar/ Bomba de refrigerante externa: 0,8 kW, 6 bar, 20 L/min/ Orientación eléctrica del husillo / Chorro de aire para limpieza del plato

- Sistema anticolisión (CAS)/Preparación del transportador de virutas/Husillo de gran diámetro ASA 6": 22/15 kW, 3800 rpm/ Posicionamiento de alta precisión del eje C/ Eje B continuo/ Almacén de herramientas con 60 posiciones/ Software con resolución de 0,1 micras/ Biblioteca API 2 para OSP-P300S/ Transportador de virutas estándar en el lado derecho/ Bomba de refrigerante de 15 bares y 20 l/min/ Unidad de filtración con 4 bolsas de filtro de tela (25 micras), bomba de 15 bares y 20 l/min.

- Plato SCHUNK ROTA THW+260-81R A8 con cilindro KITAGAWA SS1770 para husillo principal Big Bore

- Plato SCHUNK ROTA THW+215-66 A6 con cilindro KITAGAWA SS1452 para subhusillo

- Kit de mecanizado del eje Y: Interpolación helicoidal /Función de torneado del eje Y con portaherramientas de torneado desplazado/ Conversión de coordenadas /Sistema de sujeción de doble presión para el mandril del husillo principal mediante códigos M (irreversible) /Sistema de sujeción de doble presión para el mandril del subhusillo mediante códigos M (irreversible).

- Kit de mecanizado de 5 ejes: Super NURBS en 5 ejes /Control vectorial /Interfaz DNC-DT /Control de posición de la herramienta/ Transformación de coordenadas 3D /Interpolación helicoidal (incluye software de perfil de plano inclinado)

Beneficios de la máquina

Ventajas técnicas de la máquina

- Husillo principal y subhusillo: asa 8, 15 kw, 5000 rpm, 651 mm de capacidad de barra / diámetro máximo de torneado: ⌀630 mm / giro y distancia entre narices de husillo: 1290 mm / eje b: continuo, indexación 0. 001°, hsk63, 11 kw, 6000 rpm / husillo de fresado hsk a63: 10000 rpm, 16/11 kw

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos