Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

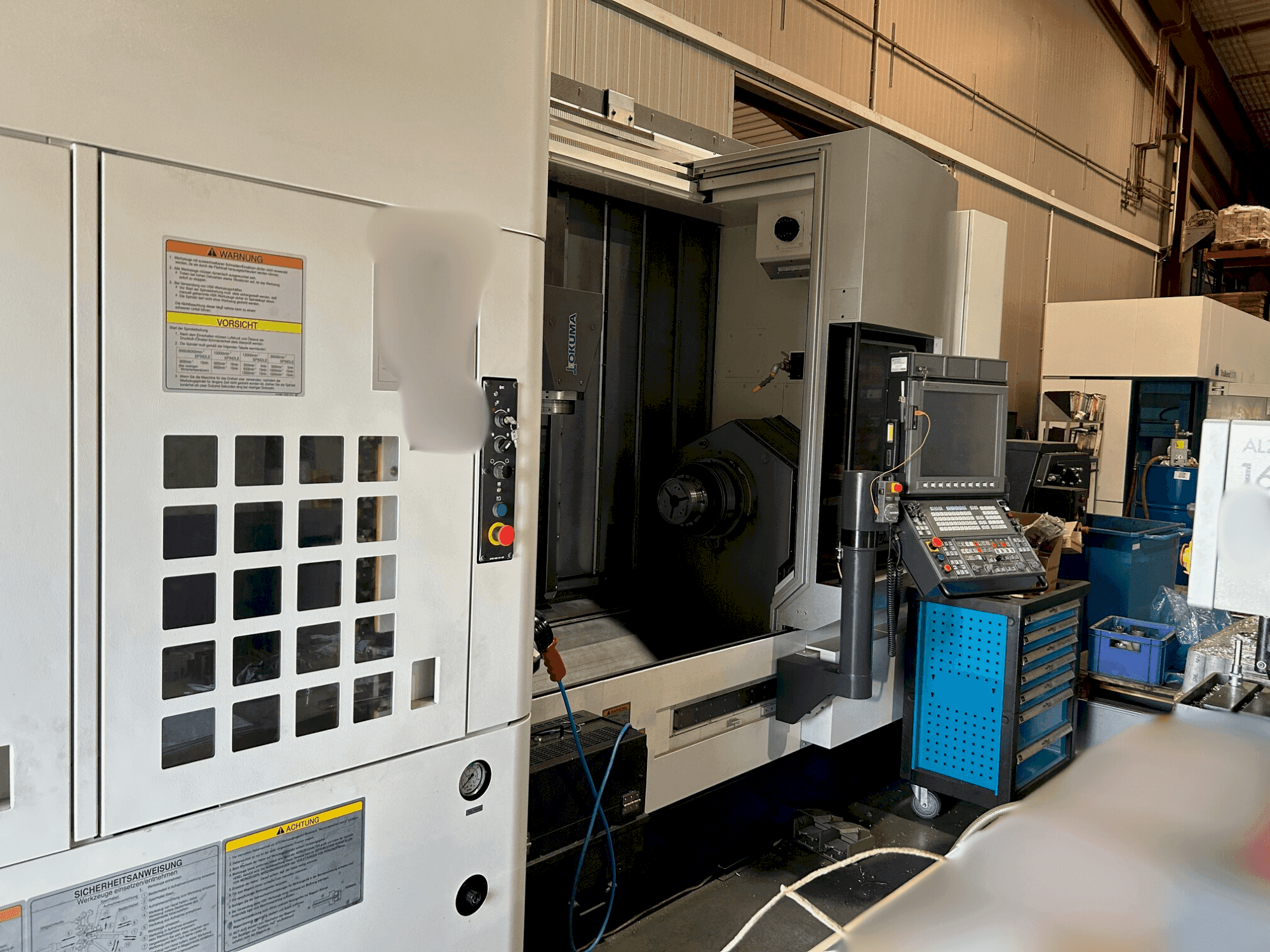

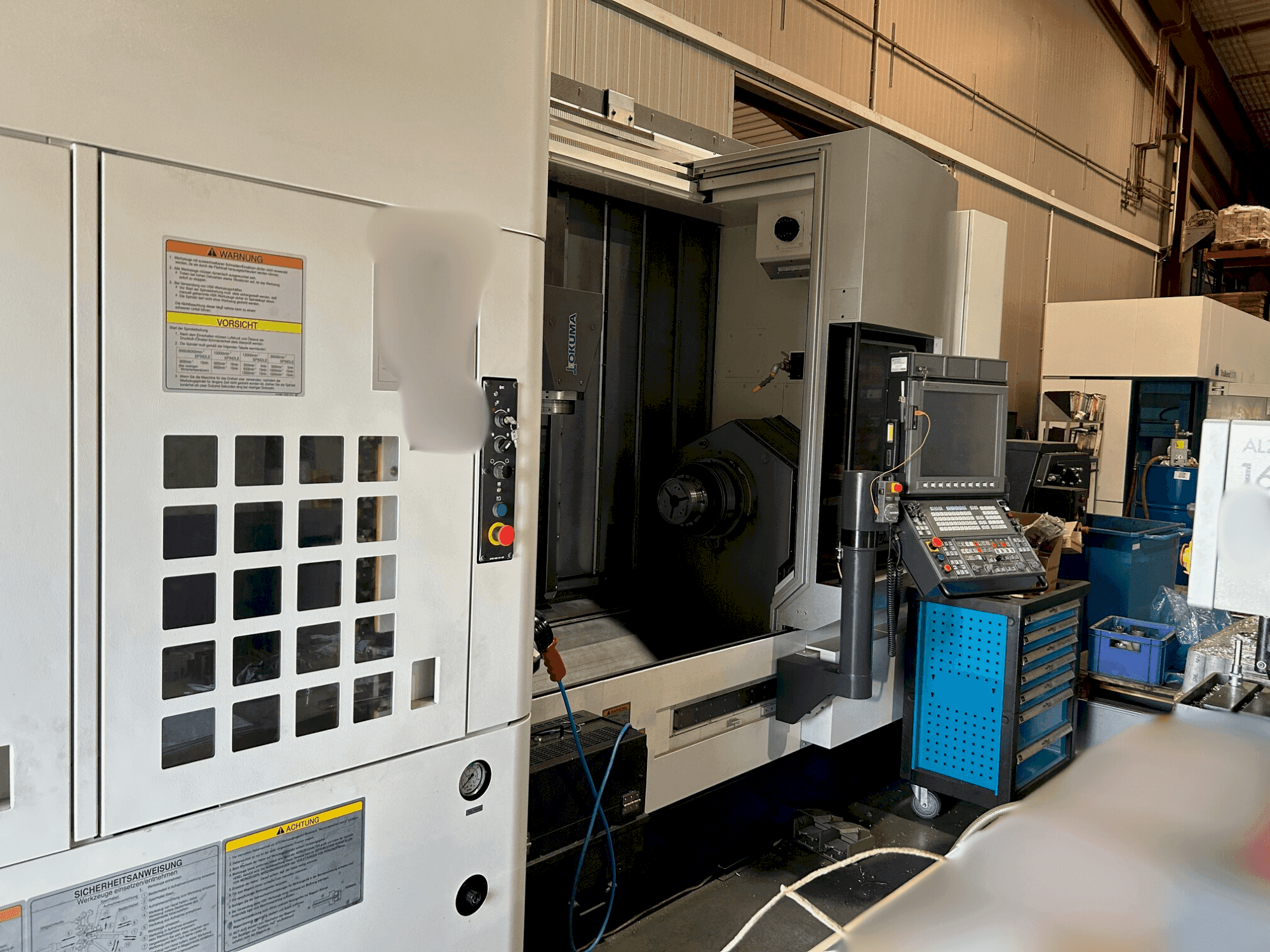

Okuma - Multus U3000 1SW 1500DE-MIL-OKU-2023-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Venta de Okuma Multus U3000 1SW 1500 usados | gindumac.com

Este Okuma Multus U3000 1SW 1500 de 6 ejes se fabricó en 2023. Se trata de un centro de mecanizado vertical con un basculante de 650 mm de ø, que puede mecanizar un diámetro y una longitud máximos de 650 mm y 1.500 mm, respectivamente. Presume de amplios recorridos con X: 645 m, Z: 1600 mm, Y: 250 mm, W: 1594 mm y un eje C de 360 grados. Ideal para tareas de mecanizado complejas, la máquina Okuma Multus U3000 1SW 1500 que tenemos a la venta. Contacte con nosotros para más detalles sobre este centro de mecanizado vertical.

Resumen

- marca: Okuma

- año: 2023

- MODELO: Multus U3000 1SW 1500

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado vertical

- Marca de unidad de control: OKUMA

Información técnica - Okuma Multus U3000 1SW 1500

Unidad de Control

- Marca del control: OKUMA

- Modelo del control: OSP-P300SA

Dimensiones

- Profundidad de la máquina: 5425 mm

- Altura de la máquina: 2955 mm

- Peso de la máquina: 16500 kg

Recorrido

- Eje B máximo: 240°

- Eje C: 360°

- Número de ejes: 6

- Recorrido eje X: 645 mm

- Recorrido eje Y: 250 mm

- Recorrido eje Z: 1600 mm

Especificación Técnica

- Potencia del husillo: 22 kW

- Velocidad del husillo: 4200 RPM

- Refrigeración a través del husillo: Sí

Información adicional

Equipamiento adicional

- Sistema de herramientas Capto C6 para torreta H1

- Suministro interno de refrigerante para herramientas rotativas, bomba con presión máxima de 20 bar, incluido filtro de bolsa, refrigeración externa del husillo de la herramienta, bomba con presión máxima de 3 bar

- Almacén de herramientas con 80 bolsillos

- Suministro de aire externo y a través del husillo de la herramienta para tornear portaherramientas y herramientas giratorias

- Tensor de correa de bisagra Interlit ISF

- Filtro de tambor TMF 300 con depósito de limpieza 980

- Pinza programable, para piezas de ø 70 x 150 mm

- 80 posiciones de herramientas

- Diámetro del rodamiento delantero del husillo 140mm / Diámetro del agujero del husillo 91mm

- Contrahusillo 420 Nm; 5000 1/minDiámetro del rodamiento delantero del husillo 120mm

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Robustez y precisión con una gran superficie y una masa significativa para la estabilidad

- Husillo portaherramientas / 120 nm; 12. 000 1/min / ikz; 20 bar / gestión de máquinas macman

- Compensación de la altura de la herramienta en y / fresado de roscas circulares x/z/y/b/ hi-cut pro control de alta velocidad

- 10 puntos cero pieza / orientación eléctrica del husillo / capto c6 / transportador de virutas de cinta articulada interlit isf

- Filtro de tambor de artesa; depósito de limpieza 980l / almacén de carga de barras de interfaz / dispositivo de recogida de piezas para diámetro 70 x 150mm

- Interfaz del cargador del robot / medición en proceso renishaw rmp60 / unidad de extensión de control kit one-touch igf m d

- Modo máquina 3d

Ventajas técnicas de la máquina

- Voladizo sobre el sillín: 650 mm

- Distancia entre ejes: 1500 mm / longitud de giro aprox. 1500 mm

- Gran oscilación sobre la silla (ø650 mm) y diámetro máximo de mecanizado (650 mm)

- Amplios recorridos para operaciones de mecanizado versátiles

- Par 427nm / torreta h1 / eje b 0. 001° / y=250mm

- Diámetro del cilindro hueco de sujeción 86 mm

- Diámetro interior del husillo 80 mm / desplazamiento en el eje w

- Eje c 360°; precisión de posicionamiento 0. 001° / eje y con carrera +125 / -125 = 250mm / eje b 240°; posicionamiento en 0. 001°

Más información

Máquina aún en marcha

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos