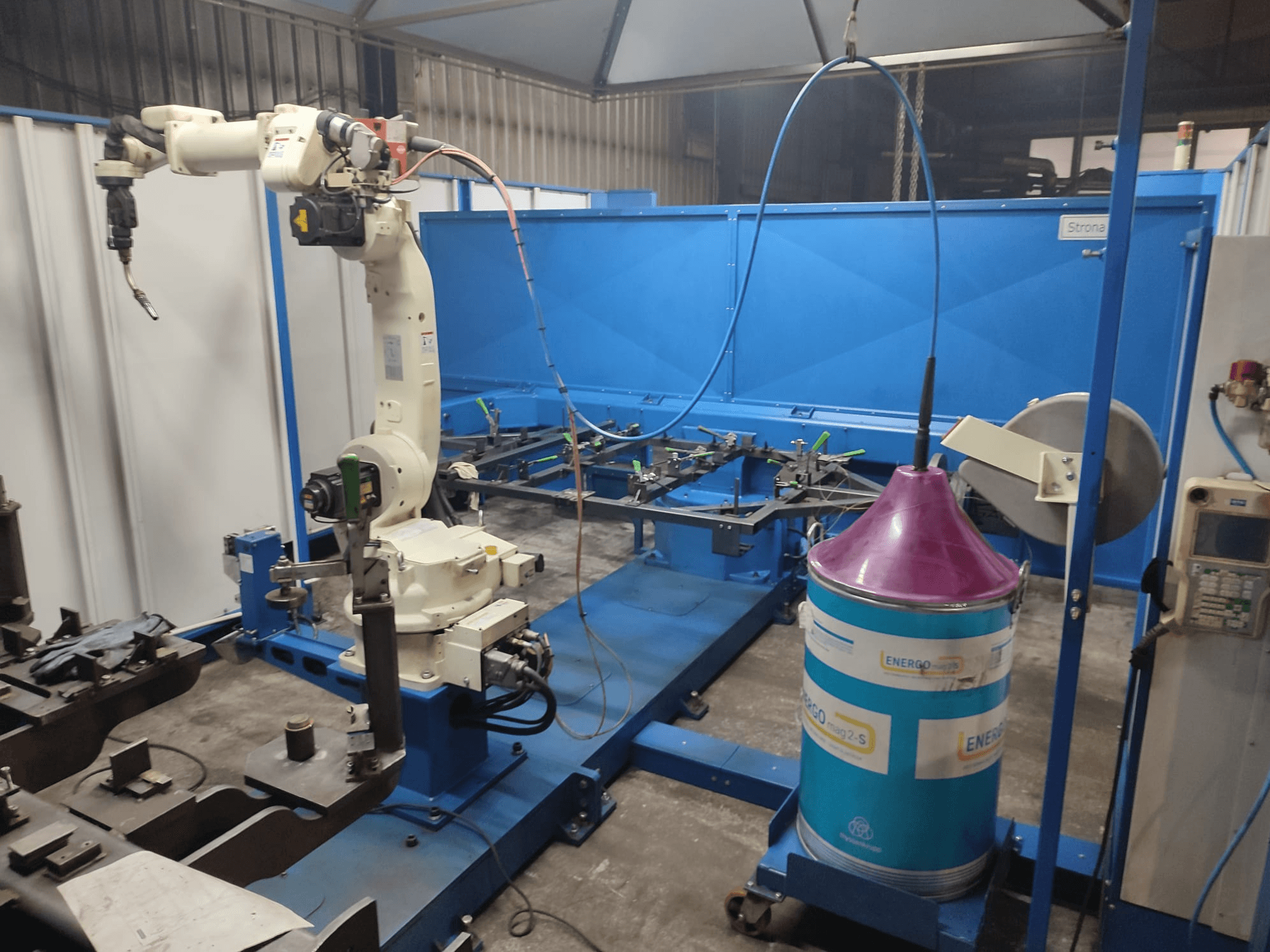

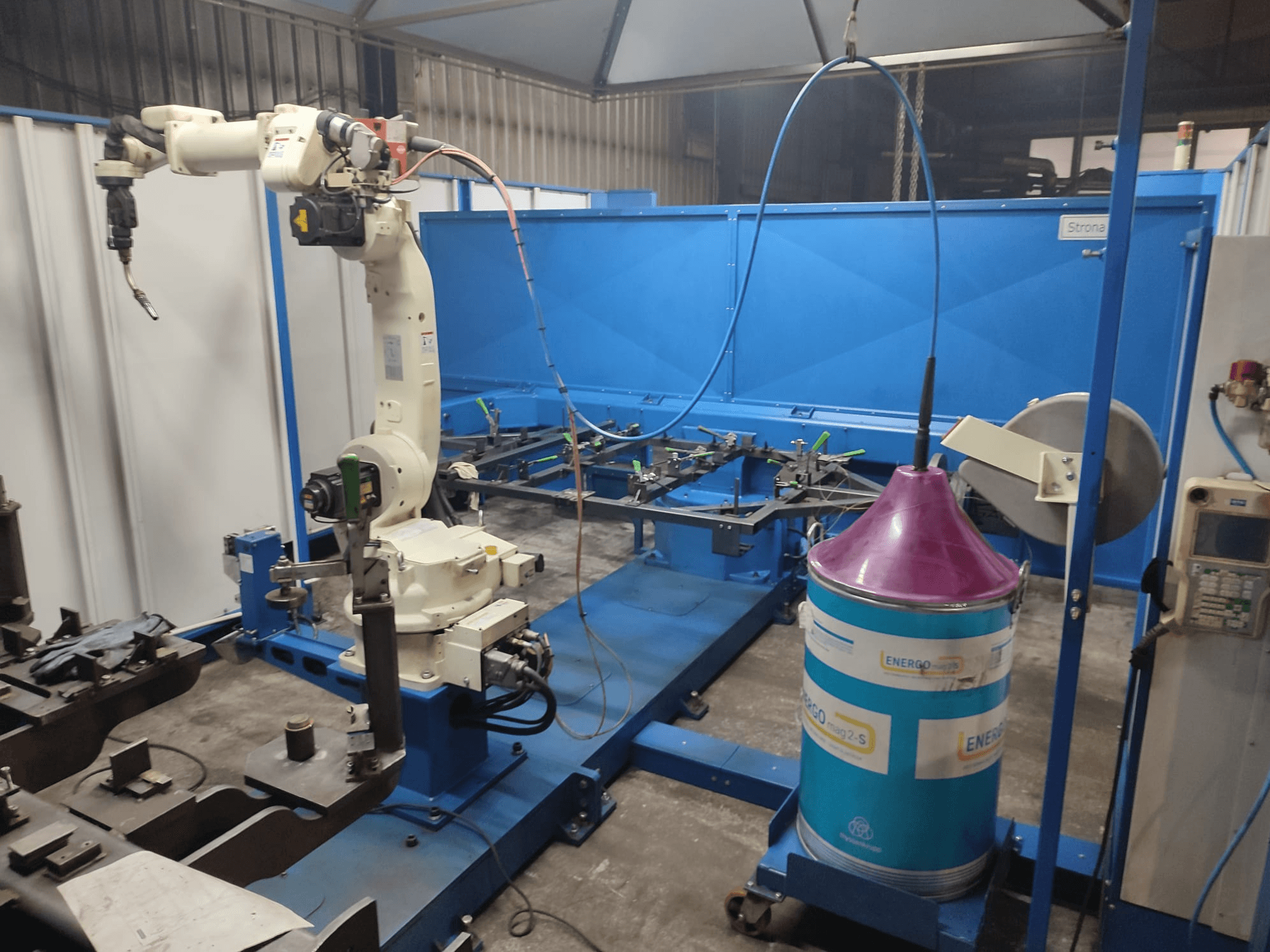

OTC Daihen - FD-B6L Robotic Welding CellPL-WEL-OTC-2018-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para chapa

- ➤ Celda de soldadura robotizada usada OTC Daihen FD-B6L | Robot.

Esta célula de soldadura robótica de 6 ejes OTC Daihen FD-B6L se fabricó en 2018. Cuenta con un robot de soldadura de seis ejes con un rango de trabajo de 2008 mm, cuatro mesas de soldadura y dos posicionadores. El sistema incluye una fuente de potencia de soldadura digital y sinérgica WB-P500L y admite soldadura MIG/MAG. La tecnología SYNCHROMOTION permite la soldadura sincronizada con el movimiento del posicionador. La configuración está diseñada para una alta productividad y un funcionamiento continuo. Póngase en contacto con nosotros para obtener más información sobre esta máquina.

Resumen

- marca: OTC Daihen

- año: 2018

- MODELO: FD-B6L Robotic Welding Cell

- horas de producción: 1000

- tipo de aplicación: Soldadura

- Ubicación: Polonia

- tipo de máquina: Robot de soldadura

Información adicional

Controlador de robot: FD-11

Colgante de enseñanza: Consola de programación original

Programación y operación: Interfaz única y unificada

Ejes: 6

Rango de trabajo: 2008 mm

Número de posicionadores: 2 piezas

Número de mesas de trabajo: 4 mesas de soldadura

Rotación oscilante de los brazos del posicionador: 180

Ejes adicionales de rotación de la pieza de trabajo 360°

Métodos de soldadura: CC, pulso CC, pulso de onda CC

Funciones: Cambios dinámicos de parámetros durante la soldadura, transiciones suaves de parámetros sin extinción del arco

Dimensiones de la máquina (LxAxA): 4,5 m x 9,0 m

Estructura y envolvente: Plataforma de estación metálica común con canales de cables integrados, carcasa de seguridad completa con paneles protectores y puertas de servicio

Modelo de fuente de potencia de soldadura: Fuente de potencia digital, sinérgica, totalmente integrada con el controlador del robot

Equipo de soldadura: Antorcha de soldadura, alimentador de alambre, paquete de cables de soldadura, estación de limpieza automática de la antorcha

Software: SYNCHROMOTION (soldadura sincrónica con movimiento del posicionador)

Estado técnico: Muy bueno

Estado: Conectado, posibilidad de pruebas in situ

Ciclo de trabajo: Funcionamiento en paralelo con soldadura en un par de mesas y carga/descarga simultánea en el segundo par. Funcionamiento continuo, alta productividad, tiempos de ciclo cortos.

Esta célula de soldadura robotizada ofrece una solución de soldadura completa gracias a su avanzado sistema de control, sus sólidas funciones de seguridad y su eficaz gestión del ciclo de trabajo, adecuada para entornos de alta productividad.

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos