Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

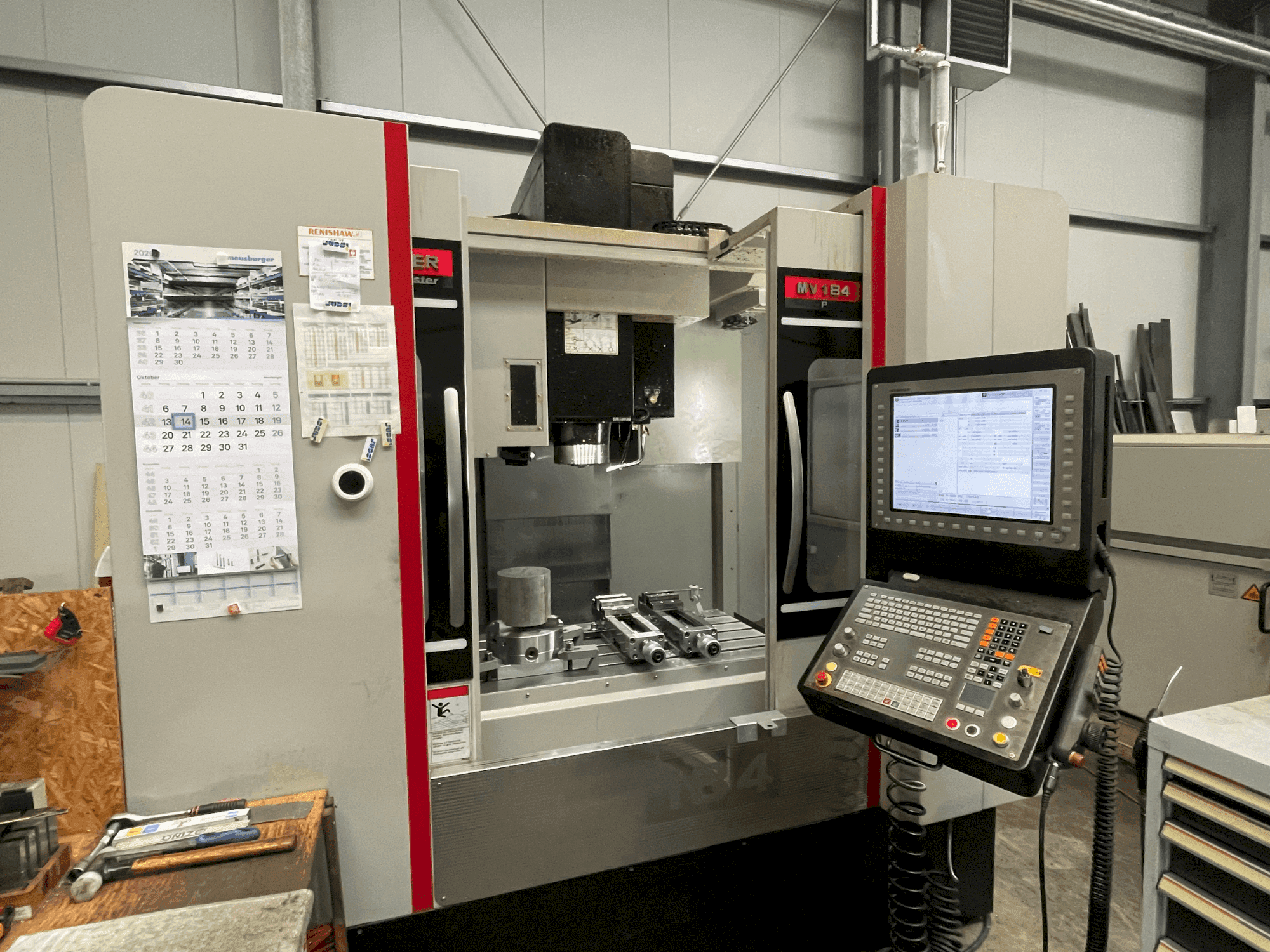

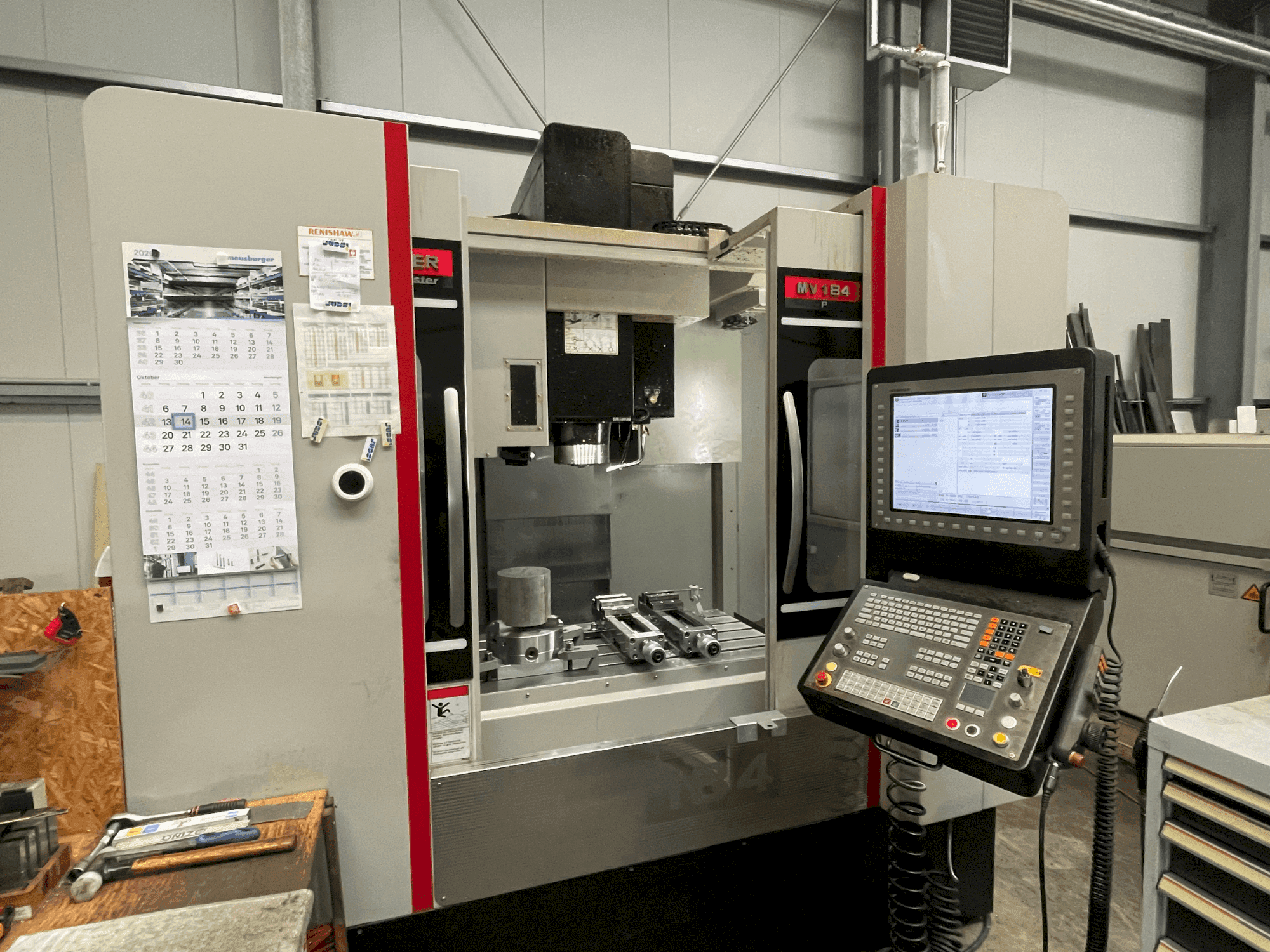

Quaser - MV 184P/12BDE-MIL-QUA-2019-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Venta de Quaser MV 184P/12B usados | gindumac.com

Esta Quaser MV 184P/12B de 4 ejes se fabricó en 2019 y cuenta con un control Heidenhain TNC640, un husillo principal accionado por correa con tipo SK40 y una mesa giratoria Lehmann. Incluye un sistema de refrigeración con control de temperatura, suministro interno de refrigerante con filtración y un filtro de tambor para la eliminación avanzada de virutas. La base de la máquina es de fundición fuertemente nervada, lo que garantiza su estabilidad y precisión. Considere la oportunidad de comprar este centro de mecanizado vertical Quaser MV 184P/12B. Póngase en contacto con nosotros para obtener más información sobre esta máquina.

Resumen

- marca: Quaser

- año: 2019

- MODELO: MV 184P/12B

- horas de producción: 17526

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado vertical

- Marca de unidad de control: HEIDENHAIN

Información técnica - Quaser MV 184P/12B

Unidad de Control

- Marca del control: HEIDENHAIN

- Modelo del control: TNC 640

Recorrido

- Número de ejes: 4

Información adicional

Pantalla/operación: Gran pantalla TFT con panel de control móvil, inclinable y giratorio

Memoria: Almacenamiento de programas en SSDR

Mando manual: Volante electrónico portátil

Cuerpo de la máquina: Base de hierro fundido pesada y estriada, optimizada para ordenador

Armario de control: Armario de control refrigerado

Señalización: Luz de señalización de tres colores

Colores: RAL 7035 Gris claro (máquina), RAL 9005 Negro azabache (depósito de refrigerante, cabezal, puerta)

Husillo principal: SK40, accionado por correa MB-4.0

Refrigeración del husillo: Sistema de refrigeración controlado por temperatura

Junta rotativa: Junta rotativa Deublin para husillo accionado por correa

Cambiador de herramientas: Cambiador de herramientas ampliado para herramientas de calentamiento

Perno de tracción: Perno de tracción con taladro

Preparación del 4º eje: Preparación del cable para el 4º eje (Quaser) con conector Harting y marco de montaje; preparación del 4º eje para la mesa giratoria Heidenhain

Refrigeración por inundación: Toberas de salida anulares en la nariz del husillo, mediante bomba Grundfos

Suministro interno de refrigerante (ICS): Con bomba Grundfos; filtro de cartucho incluido

Aire de purga del husillo: Aire soplado adicional a través del husillo, conmutable mediante función M (Heidenhain)

Tratamiento de virutas (básico): Lavado de virutas en el área de trabajo mediante bomba Grundfos; tolvas de virutas de acero inoxidable en el área de trabajo

Lubricación: Lubricación central automática para husillos de bolas; lubricación híbrida automática para guías y husillos de bolas

Equipamiento adicional

4º eje: Mesa giratoria Lehmann (monohusillo)

Plato de 3 garras: BFU.520-250ps para mesa giratoria

Motor de la mesa giratoria: Mavil ERN, listo para enchufar (conectores Harting acodados)

Filtración avanzada y evacuación de virutas: Filtro de tambor (filtración hasta [valor no facilitado]) incluido transportador de virutas de cinta rascadora

Sistema de medición de piezas y herramientas:

Receptor de infrarrojos para medición de piezas de trabajo/herramientas

Sonda de medición Renishaw OMP40-2 con control óptico de señales; incluye juego de herramientas y manual de instrucciones

Palpador recto PS3-1C con eje cerámico y bola de rubí (rosca M4)

Renishaw OTS toolsetter con transmisión modulada ópticamente, soporte de mesa ajustable, disco de palpador de carburo; incluye juego de herramientas y guía de inicio rápido

Kit de cambio de herramientas para OTS/RTS: adaptador de cambio A-5401-4030 para OTS y barra de sujeción A-5401-4032 para ranuras

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos