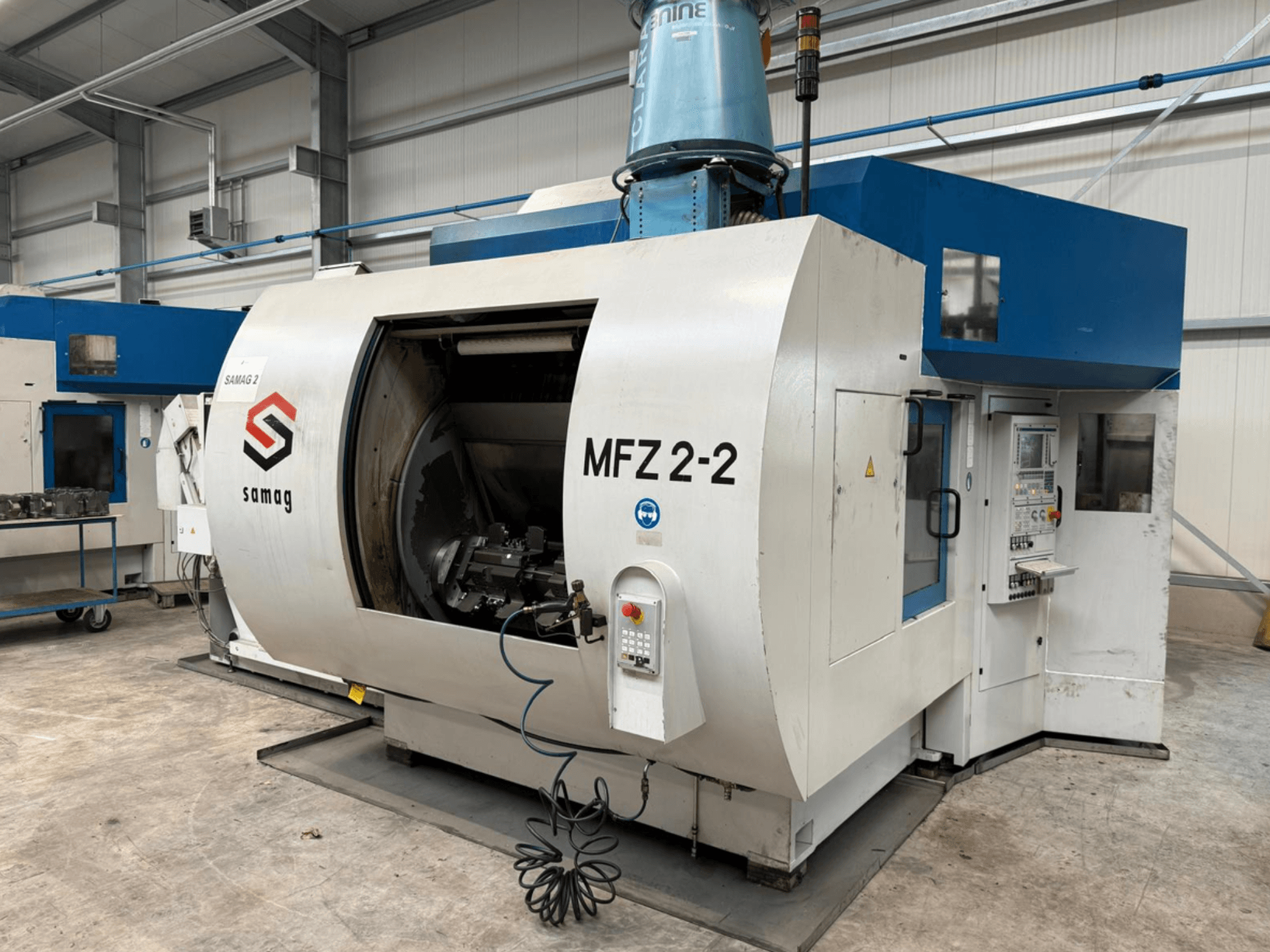

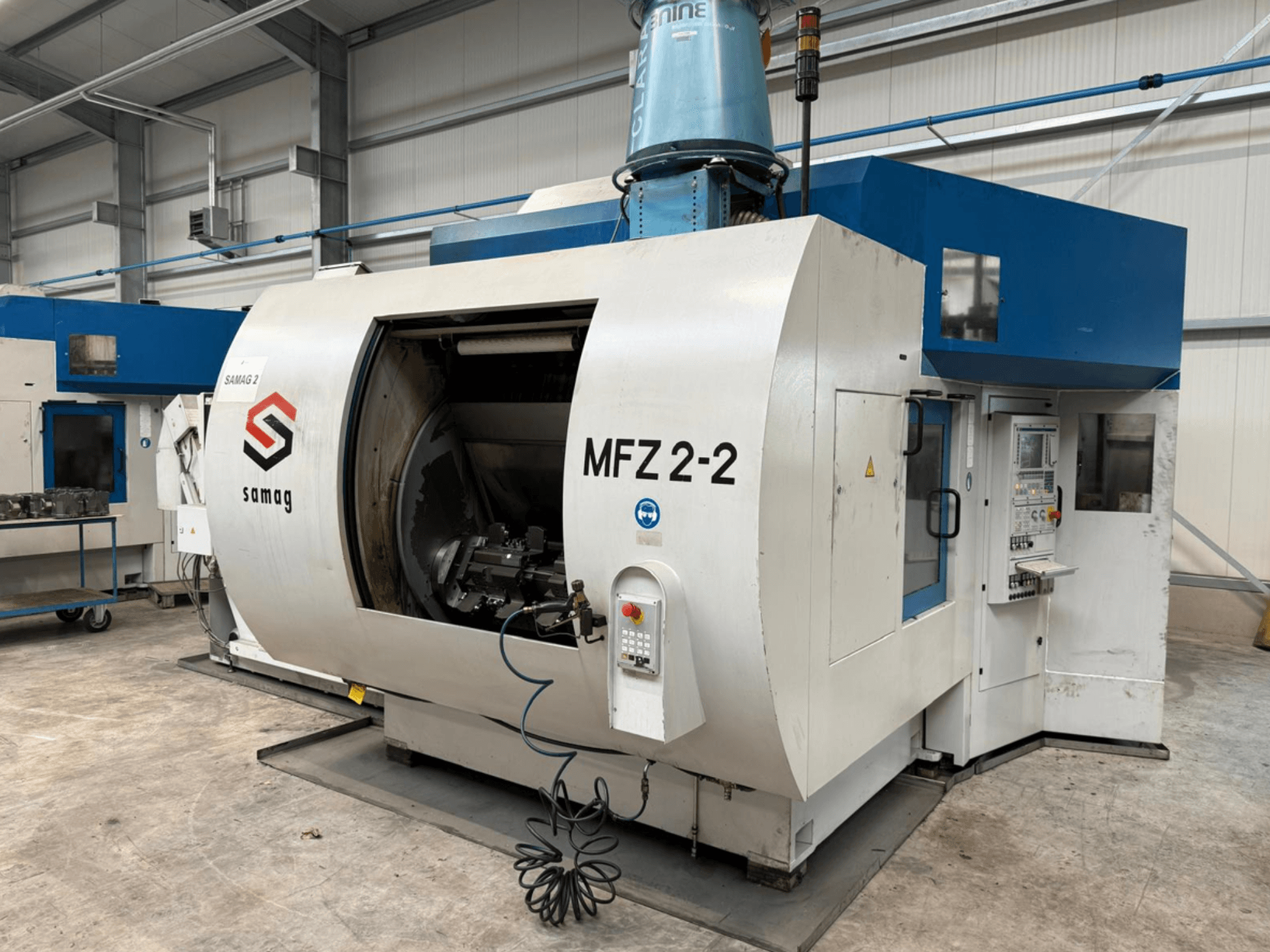

SAMAG - MFZ 2-2DE-MIL-SAM-2006-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Venta de SAMAG MFZ 2-2 usados | gindumac.com

Este SAMAG MFZ 2-2 se fabricó en 2006. Se trata de un robusto centro de mecanizado horizontal con una potencia de 72 kW que funciona con una tensión de red de 400 V y una frecuencia de 50 Hz. Con un peso de 700 kg, incluye datos 3D opcionales para torres de sujeción y piezas de repuesto. Considere la oportunidad de comprar este centro de mecanizado horizontal SAMAG MFZ 2-2. Póngase en contacto con nosotros para obtener más información.

Resumen

- marca: SAMAG

- año: 2006

- MODELO: MFZ 2-2

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado horizontal

Información técnica - SAMAG MFZ 2-2

Dimensiones

- Profundidad de la máquina: 5500 mm

- Altura de la máquina: 3000 mm

- Peso de la máquina: 22000 kg

Recorrido

- Recorrido eje X: 450 mm

- Recorrido eje Z: 450 mm

Especificación Técnica

- Max. Tool Weight: 8 kg

- Velocidad del husillo: 16000 RPM

Información adicional

Almacenamiento de herramientas

Tipo: Decágono

Número de ubicaciones de almacenamiento: 100 (2x50)

Número de casetes: 10

Ubicaciones de los casetes: 10

Paso de casete: 90 mm

Velocidad máxima del cargador de casetes: 8,3 min.

Tiempo de retardo desde la velocidad máxima del almacén de casetes hasta la parada: 300 ms

Masa máx. de carga de la herramienta: 280 kg

Peso máx. de la herramienta (pinza de plástico): 6 kg

Peso máx. de la herramienta (pinza de acero): 8 kg

Diámetro máx. de la herramienta con ubicaciones adyacentes libres: 160 mm

Eje de rotación: 10x36

Tiempo de cambio del cassette más cercano (izquierda/derecha) 1.5 s

Cambio de herramienta en el husillo (media de viruta a viruta sin rotación de la rueda, VDI 2852): 4.5 s

Ejes y recorridos

Recorridos de desplazamiento: Carrera de trabajo Y (vertical) 500 mm; Carrera total Y (vertical) incl. cambio de herramienta 775 mm

Aceleración del eje (X/Y): 0,6 xg, 0,8 xg

Accionamiento del husillo principal

Unidad de husillo: Husillo de alta frecuencia GMN HCS 220-16000/28

Distancia entre husillos 450 mm

Diámetro del manguito: 220 mm

Peso de la unidad de husillo: 110 kg

Motor de accionamiento 1FE1 083-4WN11-1BA2

Par (S1): 65 Nm

Par (S2): 74 Nm

Unidad portapiezas (unidad de giro del eje W)

Tiempo de giro 180 4.5 s

Diámetro plato/contracojinete: 500/345 mm

Velocidad de accionamiento/contracojinete (máx.): 15/20 min

Momento de inercia de la masa: 140 kgm².

Momento de vuelco admisible: 8000 Nm

Momento tangencial admisible (accionamiento/contracojinete): 10.000/5.000 Nm

Fuerza de bloqueo del engranaje Hirth a 100 bar (accionamiento/contracojinete): 190/175 kN

Portapiezas eje A1/A2

Ángulo de tronzado: 3

Tiempo de giro 180 3.5 s

Diámetro plato/contracojinete: 345 mm

Velocidad (máx.) 20 min

Momento de inercia de la masa: 20 kgm

Momento de vuelco admisible 3.000 Nm

Par tangencial admisible (accionamiento/contracojinete): 5.000 Nm

Tensión de red: 400 V

Frecuencia: 50 Hz

Tensión de control DC 24 V

Potencia nominal: 72 kW

Equipamiento adicional

Sistema de lubricante refrigerante (gestión de virutas)

Tipo: Cinta transportadora rascadora

Dimensiones (L x A x A): 2885 x 1095 x 1830 mm

Altura de descarga: 1020 mm

Tamiz de separación: 500 μm

Volumen de llenado: 100 l

Bomba de aguas residuales: 380 l/min a 1,6 bar

Unidad central de refrigeración

Tipo: DK 160-V/SO

Capacidad de refrigeración: 1900 W

Temperatura ambiente mín./máx: 10/40 °C

Temperatura máx. de salida del agua: 20 °C

Temperatura de condensación: 40 °C

Refrigerante R134a, 2 kg

Potencia eléctrica conectada: 5,1 kW

Masas periféricas

Masa del depósito de agua limpia (vacío) 930 kg

Masa del transportador de virutas (vacío) 450 kg

Una máquina de sacrificio (opcional)

Datos en 3D/CAD de la torre de sujeción (posibilidad de 3 sujeciones) (opcional)

2 torres de recambio y paquete de piezas de repuesto (opcional)

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

Documentos

José María García

Opciones de pago

Pago por adelantado

Financiación de activos