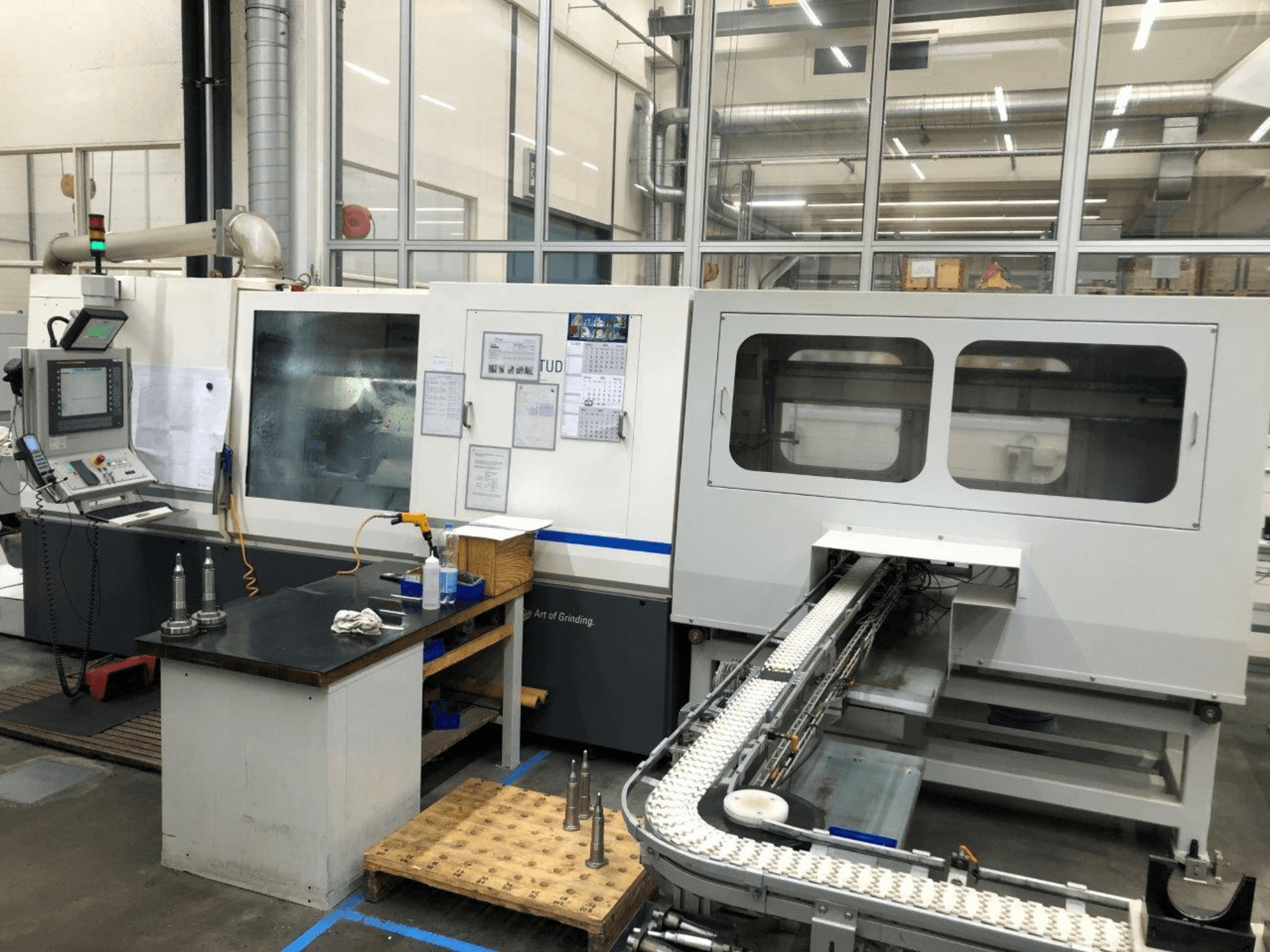

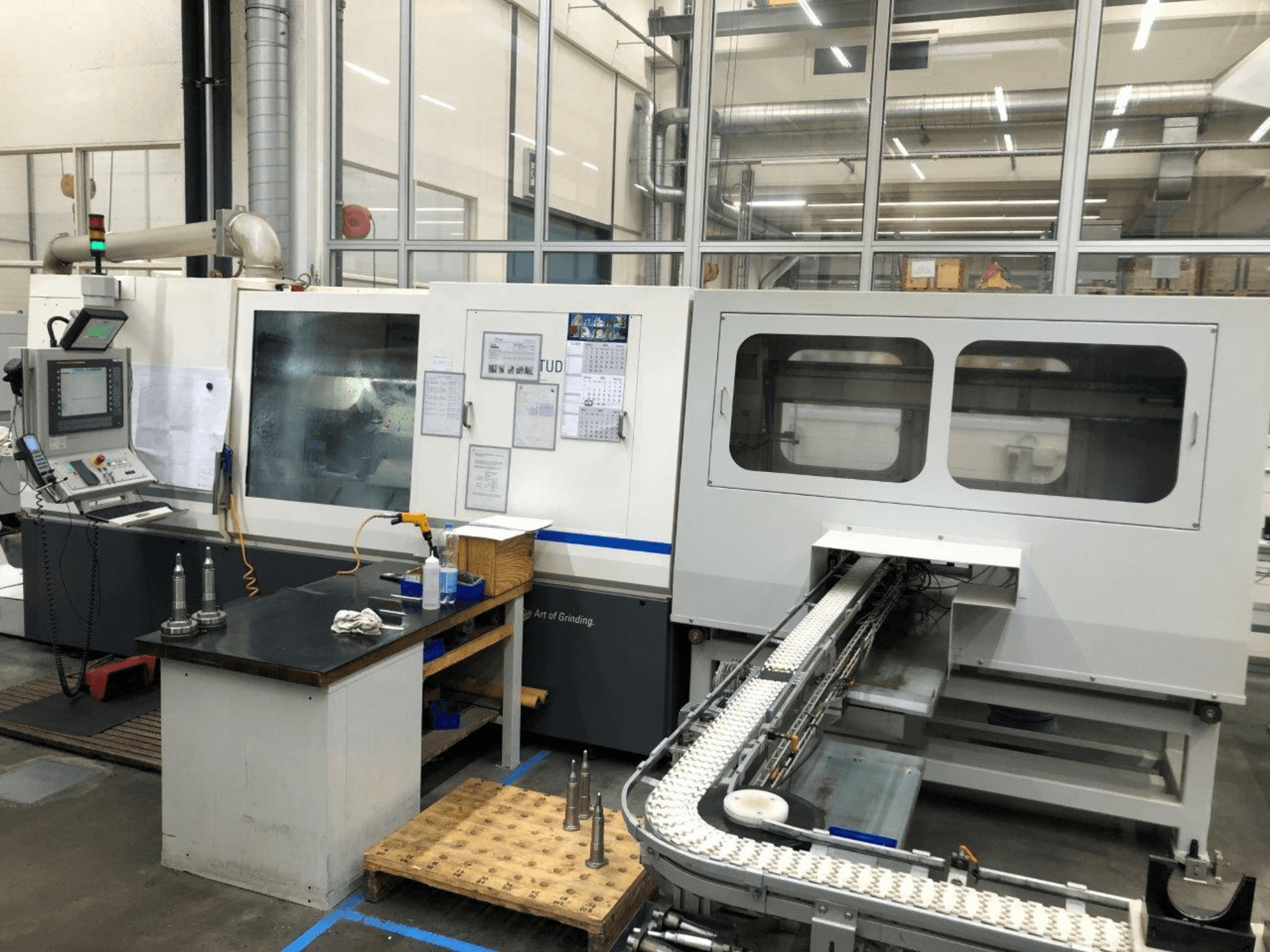

STUDER - S242CH-GRI-STU-2008-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Venta de STUDER S242 usados | gindumac.com

Esta STUDER S242, fabricada en 2008, es una rectificadora cilíndrica conocida por su robustez y precisión. Tiene un diámetro de giro de 180 mm, un peso máximo de pieza de 20 kg y velocidades de husillo de rectificado de hasta 50 m/s. La máquina incluye automatización del eje, muelas de rectificado, y todavía está encendida y en pleno funcionamiento. El mantenimiento anual realizado por Studer garantiza su fiabilidad. Si desea más información sobre esta máquina, póngase en contacto con nosotros.

Resumen

- marca: STUDER

- año: 2008

- MODELO: S242

- tipo de aplicación: Rectificado

- Ubicación: Suiza

- tipo de máquina: Rectificadora Cilíndrica

Información técnica - STUDER S242

Dimensiones

- Peso de la máquina: 12000 kg

Recorrido

- Recorrido eje X: 450 mm

- Recorrido eje Z: 850 mm

Información adicional

Distancia entre ejes: Pequeña (2 carros transversales) 400 mm; Larga (2 carros transversales) 800 mm; Larga (3 carros transversales) 800 mm

Diámetro de giro: 180 mm

Peso máx. de la pieza: 20 kg

Eje X (carro transversal)

Velocidad: 0,001-1.500 mm/min

Resolución 0,00001 mm

Eje Z (carro longitudinal)

Recorrido máx.: 850 / 1.600 mm

Velocidad: 0,001-25.000 mm/min

Resolución: 0,00001 mm

Torreta giratoria

8 estaciones: Capto 6 fijo

12 estaciones: VDI 40 fija

8 estaciones: VDI 30 accionada fija

Velocidad máx. de accionamiento: 4.000 rpm

Potencia motriz: 2,5 kW

Opción: Barra de medición longitudinal activa en la torreta (Capto o VDI)

Cabezal de rectificado

Ángulo de montaje: -25° / +25

Velocidad de rectificado: 50 m/s

Tamaño de muela: Ø 400 x 50 (63) x 127 mm

Accesorio de rectificado interior

Posiciones del husillo en la placa giratoria: 3

Posición del husillo 0° / +45°

Posicionamiento automático en 3 posiciones

Rango del husillo de rectificado interno 1.200-120.000 rpm

Velocidades de husillo disponibles: 24.000-120.000 rpm

Cabezal portapiezas (fijo)

Rango de velocidades: 1-7.500 min-¹

Potencia motriz: 10,5 kW

Portaherramientas: MK4 / DIN 55026 A4

Carga durante el rectificado superficial 500 Nm

Precisión de redondez: 0,0004 mm

Portaherramientas (orientable)

Margen de giro: 0-10°

Resolución 0.0001°

Rango de velocidad: 1-4.000 min-¹

Potencia motriz: 10,5 kW

Portaherramientas: MKS / DIN 55026 A6

Carga durante el rectificado superficial 500 Nm

Precisión de redondez: 0,0004 mm

Eje W / Contrapunto

Recorrido máx.: 450 / 1.650 mm

Velocidad: 0,001-1.500 mm/min

Ajuste fino para correcciones de cilindricidad: ±0,01 mm

Opción: Retroceso de la caña ±0,40 mm

Diámetro de la caña: 60 mm

Cono de montaje: MK4

Recorrido de la caña: 45 mm

Contrapunto síncrono opcional: 1-7.500 rpm; potencia de accionamiento 10,5 kW; cono de montaje MK4 / DIN 55026 A4

Reavivado

Herramienta de reavivado de pie, soporte con montura MK1

Diamante de una punta / teja acortada

Husillo de reavivado con accionamiento axial sobre soporte giratorio: Ø 58 / 89 / 100 mm máx.

Husillo de reavivado con accionamiento axial en la parte trasera: Ø 100 mm máx.

Valores de conexión

Carga total conectada 45 kVA

Presión de aire mínima: 5,5 bar

Peso total: 7.600 / 12.000 kg

Estado y servicio

Todavía en funcionamiento

Sin trabajos de desbaste

Mantenimiento anual por Studer

Equipamiento adicional

Automatización de ejes (incluida en el volumen de suministro)

Muelas (incluidas)

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos