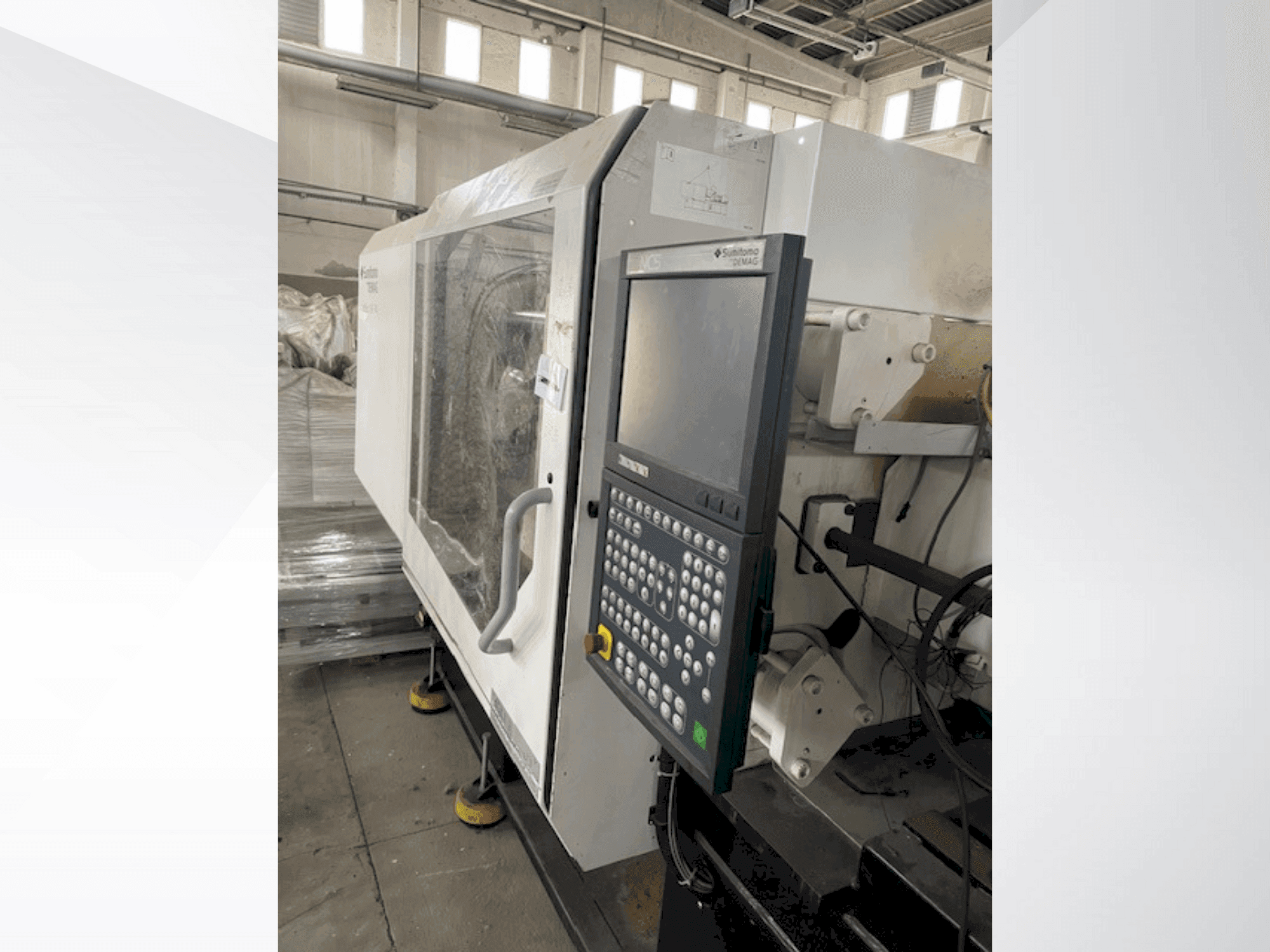

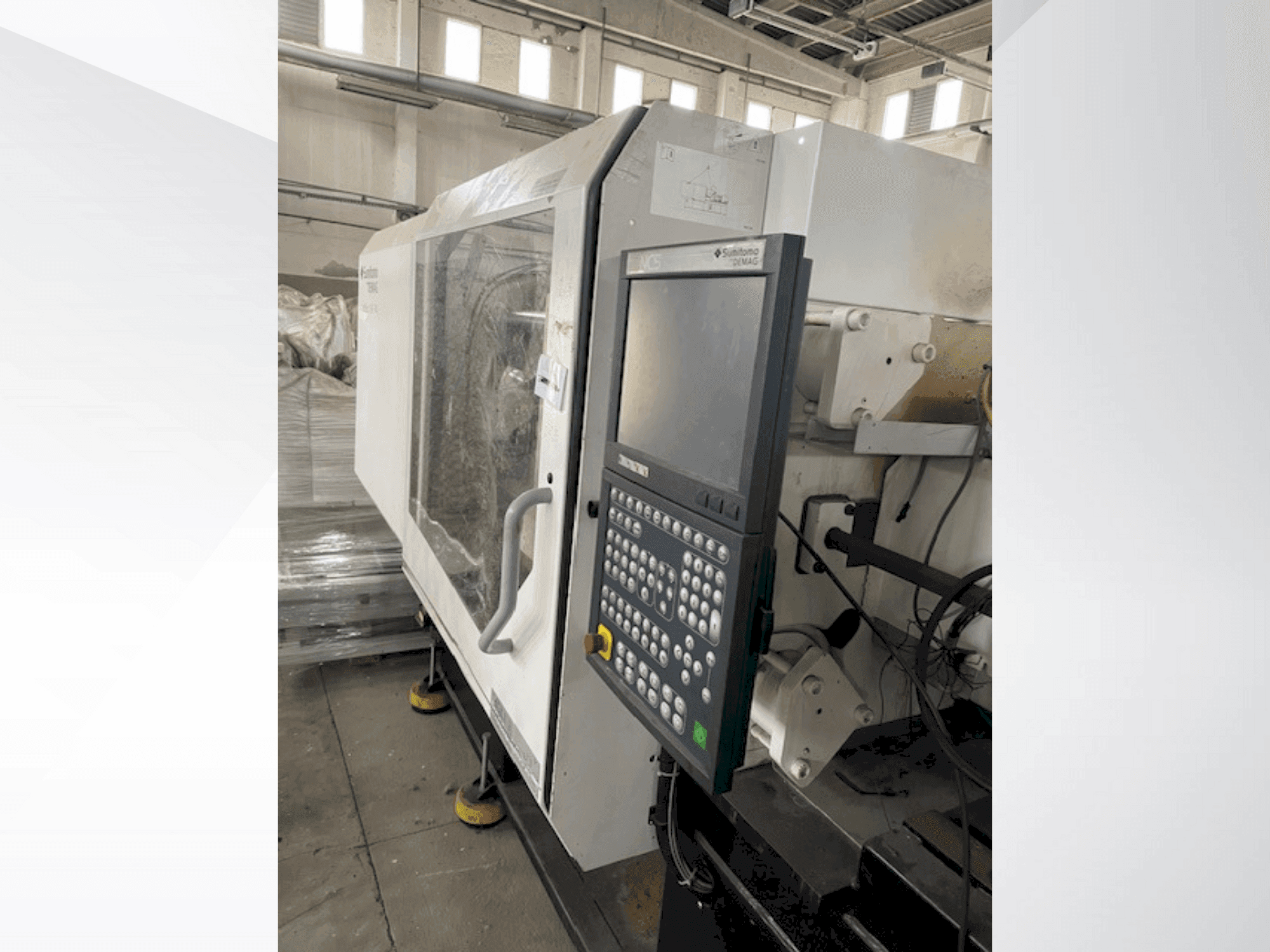

SUMITOMO SHI DEMAG - IntElect 160/520-340 smartDE-INJ-SUM-2013-00003

¿Tiene más preguntas? ¡Contáctenos!

Borja Garcia

+34 679 019 350

b.garcia@gindumac.com

- GINDUMAC

- Productos

- Maquinaria de procesamiento de plástico

- ➤ Used SUMITOMO SHI DEMAG IntElect 220/610-750 smart For Sale

This SUMITOMO SHI DEMAG IntElect 220/610-750 smart was manufactured in 2013. It's an electrical injection moulding machine known for its precision and efficiency. Ideal for those looking to enhance their production capabilities with reliable technology. Contact us for more information.

Resumen

- marca: SUMITOMO SHI DEMAG

- año: 2013

- MODELO: IntElect 160/520-340 smart

- horas de producción: 17577

- tipo de aplicación: Moldeo por inyección

- Ubicación: Alemania

- tipo de máquina: Máquina de moldeo por inyección eléctrica

Información técnica - SUMITOMO SHI DEMAG IntElect 160/520-340 smart

Dimensiones

- Profundidad de la máquina: 5370 mm

- Altura de la máquina: 2060 mm

Especificación Técnica

- Fuerza de cierre: 1600 kN

Información adicional

Additional equipment

- Sepro Robot SDR 11

Machine Benefits

Technical Machine Benefits

- Clamping unit: 160 / locking force: 1760 kn / opening stroke max: 495 mm / mould installation height, min: 275 mm / mould installation height, max: 585 mm

- Platen distance, max: 1080 mm / mould mounting platens (h x v): 760 x 785 mm / clear column distance (h x v): 520 x 520 mm

- Ejector travel: 125 mm / ejector force: 35 kn

- Injection unit: 340 / screw diameter: 35 mm / l/d ratio: 20 / injection flow (ps) without accumulator: 288 cm³/s

- Metering stroke: 162 mm / nozzle stroke, max: 350 mm / nozzle immersion depth (svo): 20 mm / nozzle contact pressure: 30 kn

- Material hopper capacity: 35 l / injection speed, max. , standard: 300 mm/s / injection speed, max. , increased: 500 mm/s

- Net weight without oil filling: 7300 kg

Extra Information

Electrical & Pneumatic Interfaces: Sockets: 2 x Schuko (1Ph, 230V, 10A)/ 2 x IECEE (3Ph, 400V, 16A) – switched off via main switch/ Additional Schuko socket also listed (same rating)/ Valves: 1 x Pneumatic 5/2 valve on movable platen (programmable)/ 2 x Pneumatic 5/2 valves on stationary platen (programmable)/ I/O: 3 digital inputs / 3 digital outputs (freely programmable)/ Terminal board outside control cabinet/ Air & Cooling: Central air supply and piping/ Cooling system: open cycle/ Cooling water controller: 4 circuits with temperature indication (max. 10 l/min per circuit)/ Separate water connection for cooling (mould + machine)/ Switch-off for mould cooling (time programmable)/ Machine Mechanical & Motion Features: Clamp and injection unit colours: Jet black (RAL9005): bed, pump station, lower control cabinet/ Signal white (RAL9003): clamp unit, injection unit, guards, covers, safety doors/ Mould platen layout: E-standard (similar to EUROMAP, March 1996)/ No side ejector platen/ Ejector: held in front position against spring-loaded mold ejector/ Standard mold height/ Standard closing speed/ Only active movement when safety guard is closed/ Screw: wear-resistant, nitrided barrel, standard L:D, 35 mm diameter/ Non-return valve: 3-piece ring type/ Control, Programming & Monitoring: Inputs/outputs and clamp sequence: freely programmable/ Switching programs (e.g., dry cycle, startup scrap counter, timer-controlled cooling)/ Injection process: Injection force with max injection speed: 200 mm/s/ Back pressure programmable via 6-point polygon/ Follow-up pressure switch-over based on melt pressure/ Follow-up, back pressure, metering: closed-loop control/ Feed throat temp control: closed-loop, max 90°C ±9°C/ Reduced nozzle sealing force (programmable)/ Clamp force: closed-loop control/ Active mold protection: sensor-based during closing/ Hot runner control: 5 zones integrated (2.75 kW total) Display, Software & Data: Coloured data display PDA (Process Data Acquisition): 100% control with graphical parameter recording/ Overlaid graphs for multiple cycles/ External statistical data export/ Amendment reports and maintenance indicators/ Freely programmable screens/ Flexible movement for ejector and injection unit/ Interface for: Handling device (CAN Bus)/ Nozzle heater band (plug-only)/ Dosing device (potential-free “dosing” signal)/ Eject plate monitor (for mold protection)/ Remote access: WC5 - DPG World Connect/ Safety Features: Emergency stop on non-operator side/ Nozzle sealing force only active when mold closed/ Flashing light indicator/ Safety doors & guard interlocks/ Other Mechanical/Installation/ Antivibration mounts/ Basic European design/ Electrical supply: 400V ±10%, 3Ph + N + PE, 50 Hz/ Common drive/heating line connections/ Hopper shutoff with emptying function (material hopper not included)

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

Borja Garcia

Opciones de pago

Pago por adelantado

Financiación de activos