Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

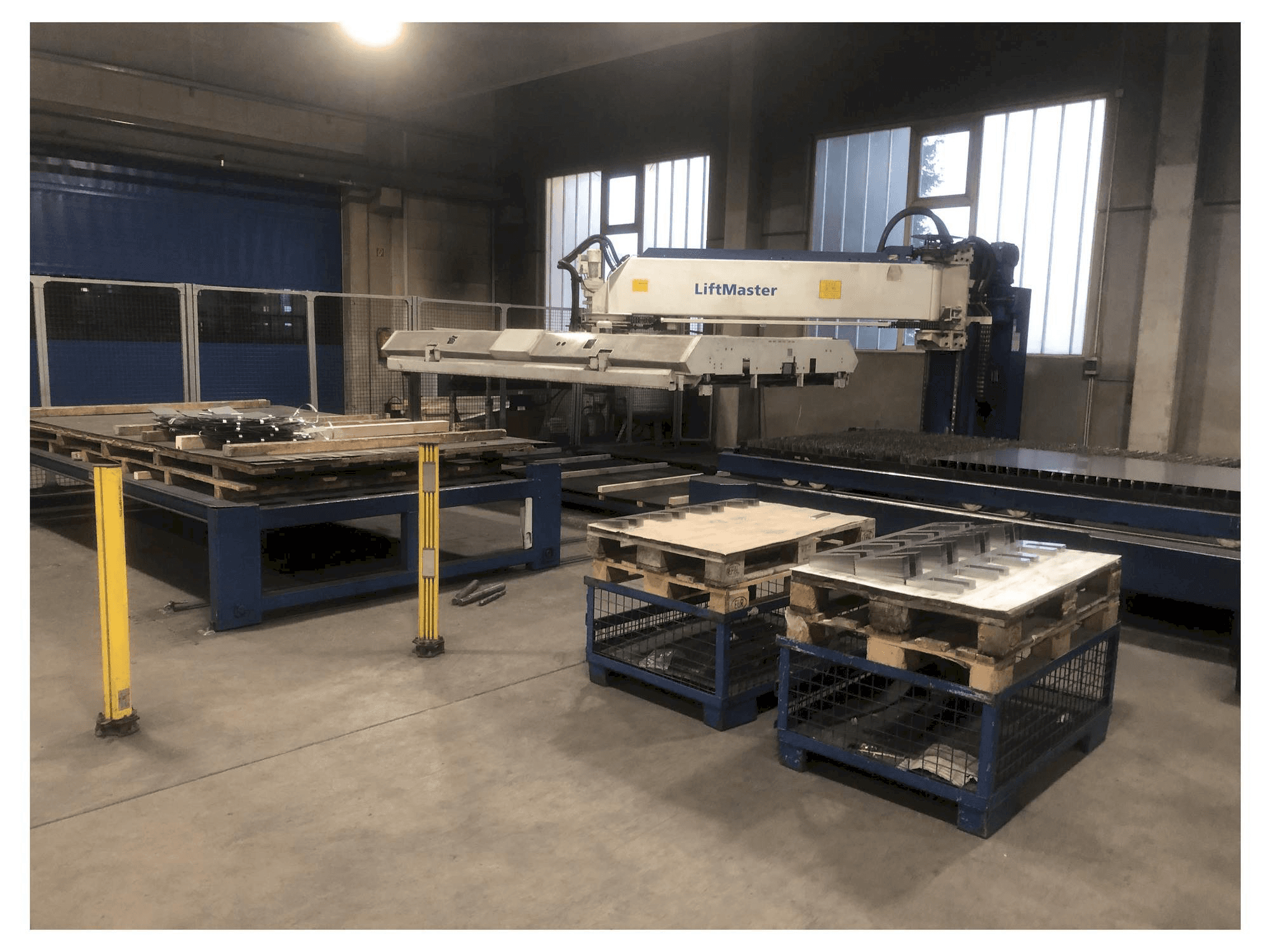

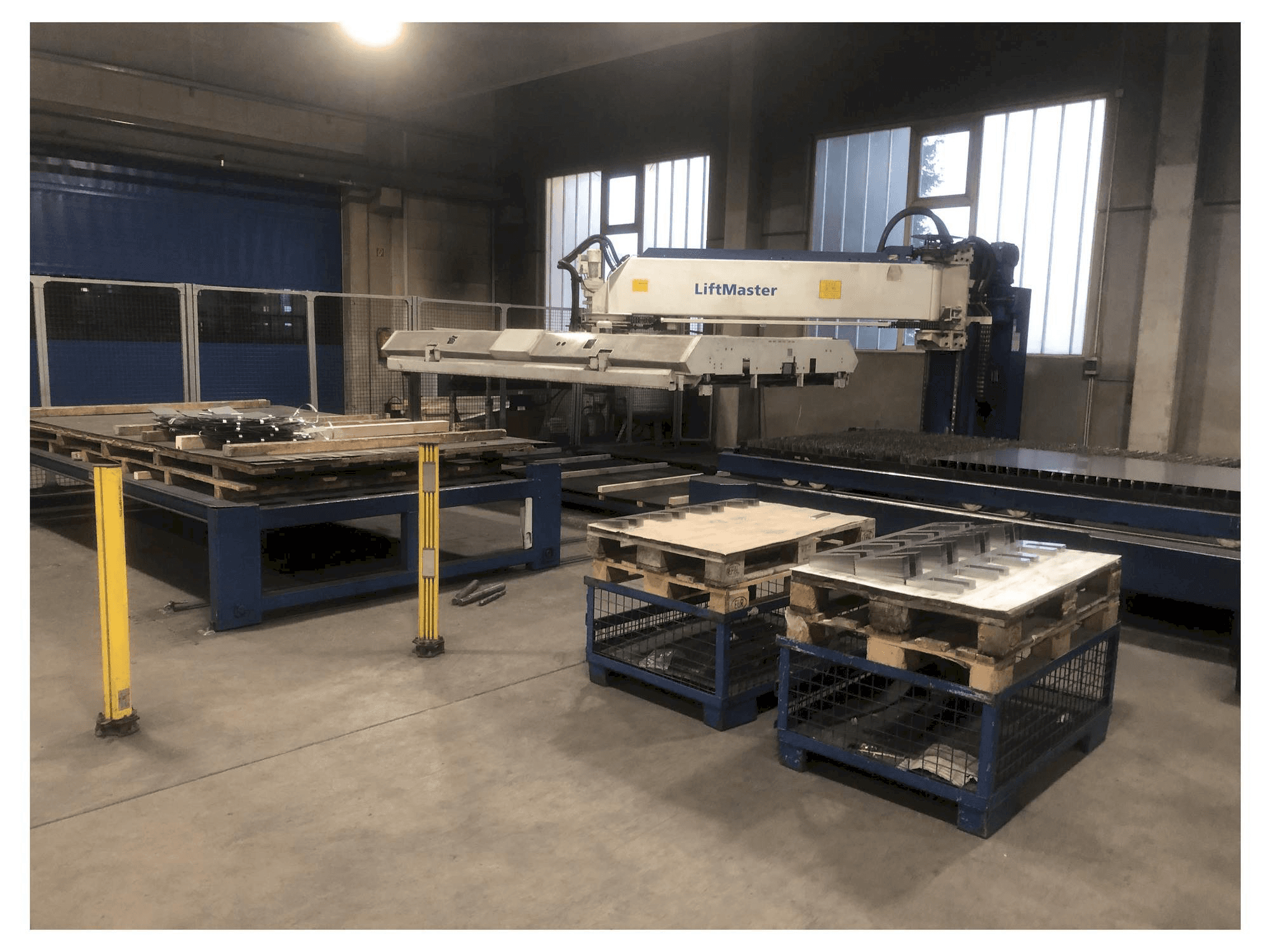

TRUMPF - TruLaser 5040 + LiftmasterDE-LAS-TRU-2007-00003

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para chapa

- TRUMPF TruLaser 5040 + Máquina de corte por láser Liftmaster

Esta máquina de corte por láser TRUMPF TruLaser 5040 + Liftmaster fue fabricada en 2007. Está equipado con una unidad de control SIEMENS SINUMERIK 840D. La máquina tiene una potencia de láser de 5,0 kW.

Resumen

- marca: TRUMPF

- año: 2007

- MODELO: TruLaser 5040 + Liftmaster

- tipo de aplicación: Corte

- Ubicación: Alemania

- tipo de máquina: Máquina de corte láser CO2

- Marca de unidad de control: SIEMENS

Información técnica - TRUMPF TruLaser 5040 + Liftmaster

Unidad de Control

- Marca del control: SIEMENS

- Modelo del control: Sinumerik 840D

Especificación Técnica

- Potencia del láser: 5 kW

Información adicional

Beneficios de la máquina

Ventajas cualitativas de la máquina

- Ajuste programable de la presión del gas de corte

- Control de altura capacitivo controlline y control de procesos

- Cabezal de corte láser con lente de 7,5" y cabezal de corte láser con lente de 10" para truflow 6000

- Cabezal de corte láser con lente de 5" y cabezal de corte láser con lente de 7. 5" para truflow 5oo0

- Dispositivo de cambio rápido del cabezal de corte

- Accionamientos: accionamiento de pórtico en combinación con accionamientos lineales accionamientos directos

- Cambiador automático de palés

- Bastidor de máquina cerrado con unidad láser integrada - unidad láser: láser de co2 excitado por alta frecuencia truflow 5000, ventilador turbo radial exento de mantenimiento, unidad de refrigeración, función de libro de registro

- Totalmente encapsulado y ventilado con nitrógeno,

- Cinta transportadora longitudinal para piezas pequeñas/residuos

Ventajas técnicas de la máquina

- Licencia de software incluida

- Procesado rápido con sprintline en todos los grosores de chapa, ciclos de potencia programables

- Línea de contorno para la producción de agujeros pequeños

- Pierceline

- Dispositivo de pulverización para el tratamiento seguro de chapas gruesas

- Detección automática del borde exterior de la chapa

- Seguridad: barreras ópticas multihaz, guiado de haces

- Corte por alta presión con nitrolina

- Ajuste automático de la posición de enfoque focusline - control de la potencia del láser

- Posición del diodo láser

Más información

Área de trabajo: 4OO0 x 2000 x 1 15 mm Equipo de estación: - PlasmaLine - Microsoldadura - Limpieza automática de boquillas - Desconexión automática - Iluminación del área de trabajo - Sistema de control Sinumerik 840D: Sistema de control abierto basado en PC, manejo sencillo, ayuda en línea, e-shop integrado, funciones de diagnóstico, libro de mantenimiento, datos tecnológicos, teleservicio - Programación de taller sistema de monitorización, sistema de aspiración multicámara y aspirador compacto, cabina de seguridad - Instalación, puesta en marcha e instrucción - Conexión de red RJ45 mediante instalación de teleservicio - Unidad de disquete de 3,5 - Pantalla TFT en color Cinta transportadora Ouer izquierda con contenedor LiftMaster Dispositivo de pelado y medidor de espesor de chapa Extensión para manipulación de palets (P) + 1x carro doble la máquina tiene un contrato de mantenimiento con Trumpf sustitución del tubo de cuarzo en 2022/2023. 00% de potencia de 5KW.

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos