Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

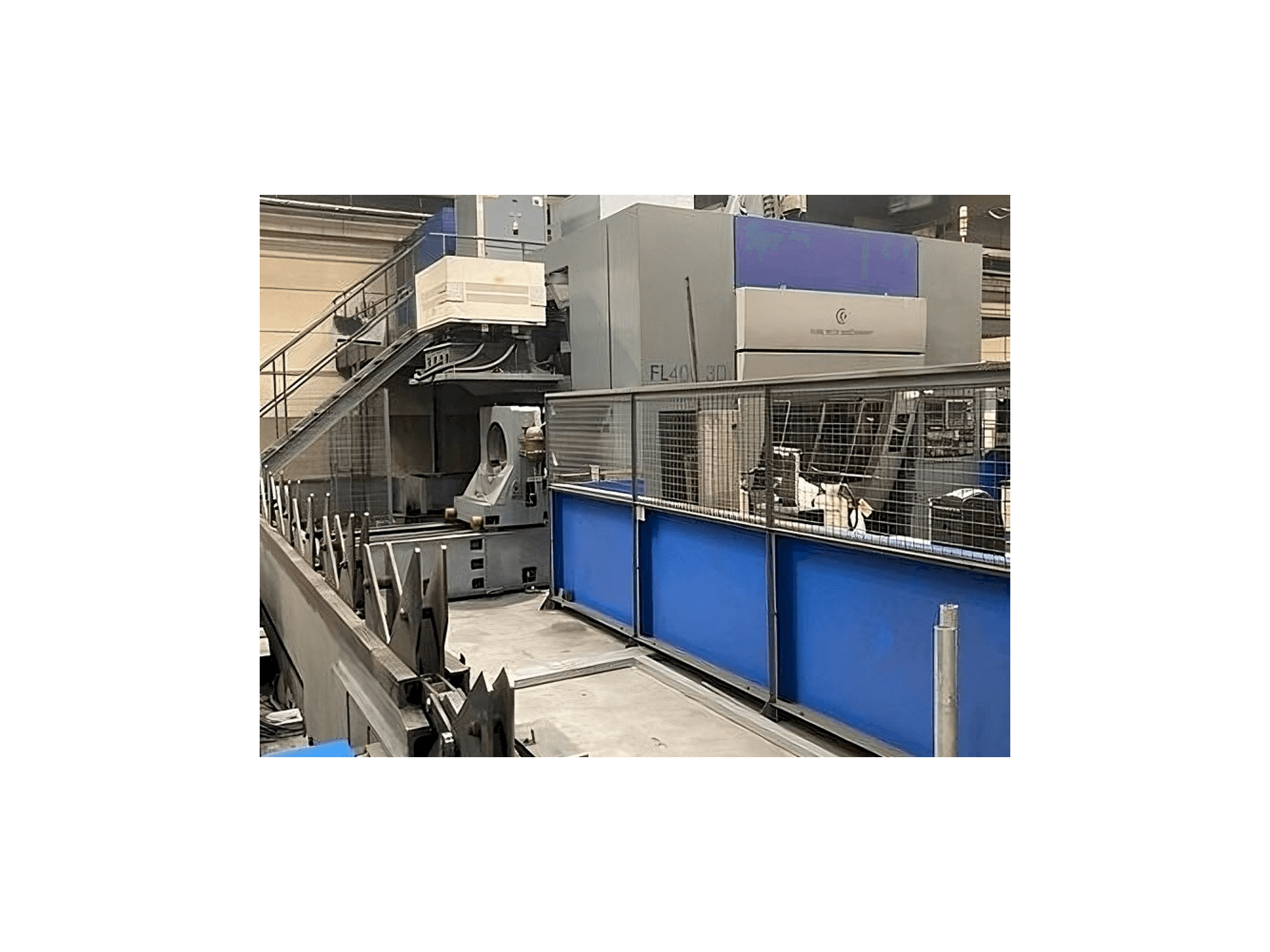

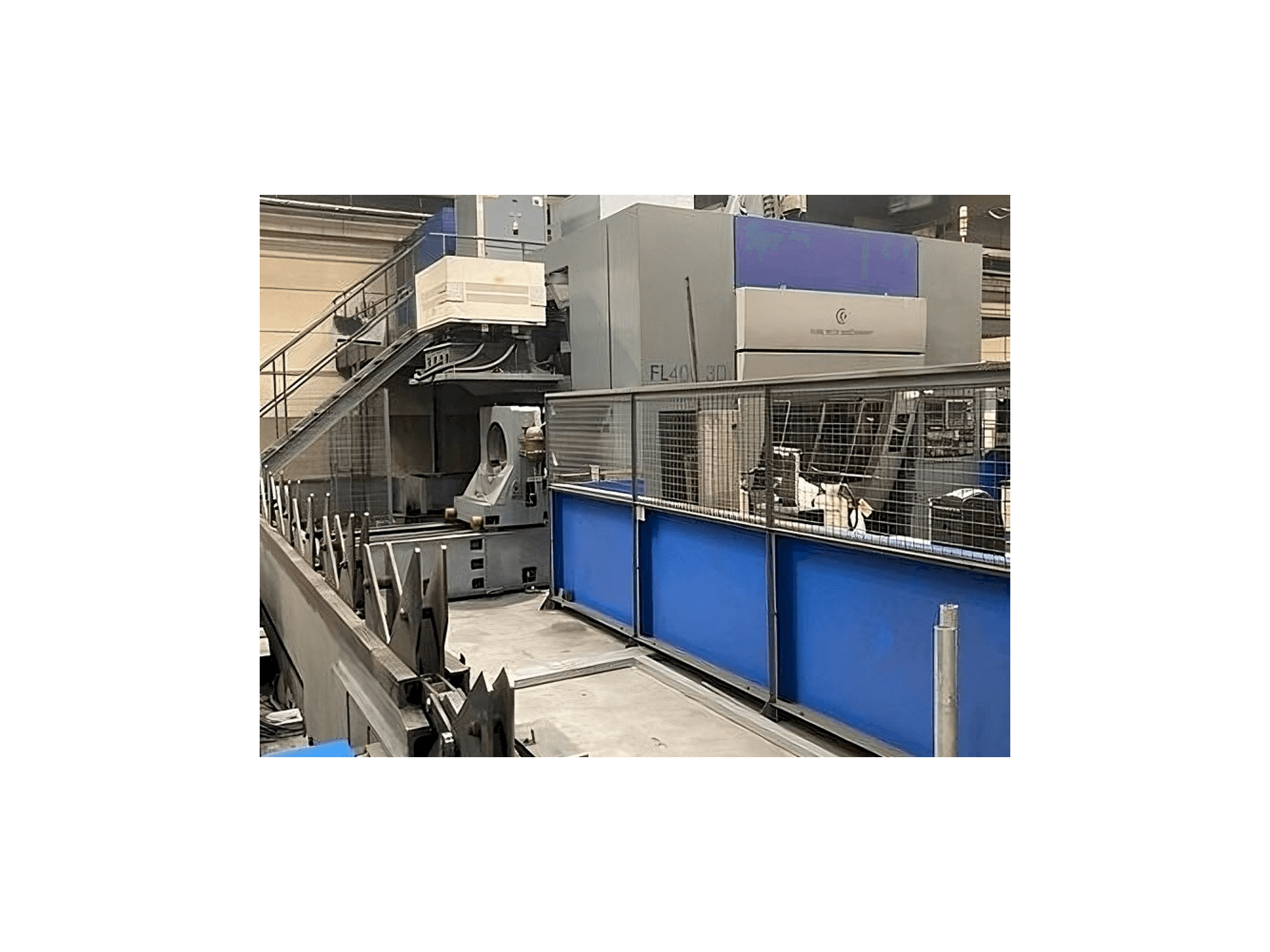

Tube Tech Machinery - FL 400 3DNL-OTH-TUB-2006-00001

Vendida

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

Contacta por Whatsapp

- GINDUMAC

- Productos

- Máquinas para chapa

- Tube Tech Machinery FL 400 3D Tube Cutting Machine

Mostrar en idioma original

This Tube Tech Machinery FL 400 3D Tube Cutting Machine was made in the year 2006 in Italy and retrofitted in 2012. It is equipped with a Siemens 840D control unit. The machine has a laser power of 4 kW.

Resumen

- marca: Tube Tech Machinery

- año: 2006

- MODELO: FL 400 3D

- tipo de aplicación: Otras máquinas para chapa metálica

- Ubicación: Países Bajos

- tipo de máquina: Máquina de chapa metálica

- Marca de unidad de control: SIEMENS

Información técnica - Tube Tech Machinery FL 400 3D

Unidad de Control

- Marca del control: SIEMENS

- Modelo del control: 840D

Dimensiones

- Profundidad de la máquina: 12000 mm

- Peso de la máquina: 95000 kg

Información adicional

Machine Benefits

Qualitative Machine Benefits

- Revision in 2012:

- Replacement of main wearing parts: - all bearings of the 4 chucks on the track - cutting head itself - igus cable reel trays that run with the chucks

- Up-to-date machine control software (by ttm)

- Inspection of all moving parts loading/unloading (front and rear) - open everything, check, lubricate, replace, close

- Commissioning tolerance tests on all axes: - accuracy - repeat accuracy

- Tube transport (mandrels): the tube is carried in and out of the machining zone (cutting zone) by means of four mandrels: there it undergoes machining, also with the help of rotation and linear movement of the same mandrels. AŌer machining the tube is then transported to the rear unloading zone or unloaded in the central unloading zone

- Loading zones (there are two types of loading):

- Front loading, performed by five parallel chains for conveying the tube and four loading manipulators to liŌ and carry the tube into the area where it will be taken over by the mandrels

- Rear loading, (or bundle loading), where the tubes are stored in bundles and loaded one by one (by means of the same four manipulators handling the front loading) and brought into the takeover area to the mandrels.

- Cutting zone: the laser beam is generated inside a trumpf source (tlf 4000), with the use of c02, n2 and he. Successively it is guided by means of a number of mirrors to the of the head, where it shall machine the workpiece. Machining is obtained by a five axis (xm, ym, zm, a, c) laser system allowing for cutting in the whole space around the head nozzle. By using the auxiliary axes u, v, w and a1 the former ones can also work by interpolation between them, exploiting (also to keep machining down) rotation and linear movements of the mandrels. Distance between nozzle and workpiece is being constantly controlled by means of precitec capacitive sensor

Technical Machine Benefits

- Loading tube length: 4000 mm min / 14000 mm max, unloading tube length: 800 mm min / 14000 mm max

- Tube weight: 290 kg/m max tube section: round, square, rectangular, oval

- Round section size: ø 40 to ø 406 mm max, square section size: 40x40 to 300x300 mm max, rectangular, oval section size: 300x250 mm max

- Diam. For loading from bundle: ø 254 mm max

- Section unloadable on chain: 800 mm min

- Mandrels linear speed: 70 m/min max

- Controlled axes: 24 - 3d laser head

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

Tu gerente de cuenta:

José María García

José María García es parte de nuestro equipo de especialistas en maquinaria usada y será tu contacto directo por consultas sobre la máquina. No dudes en ponerte en contacto.

Opciones de pago

Pago por adelantado

Financiación de activos