Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

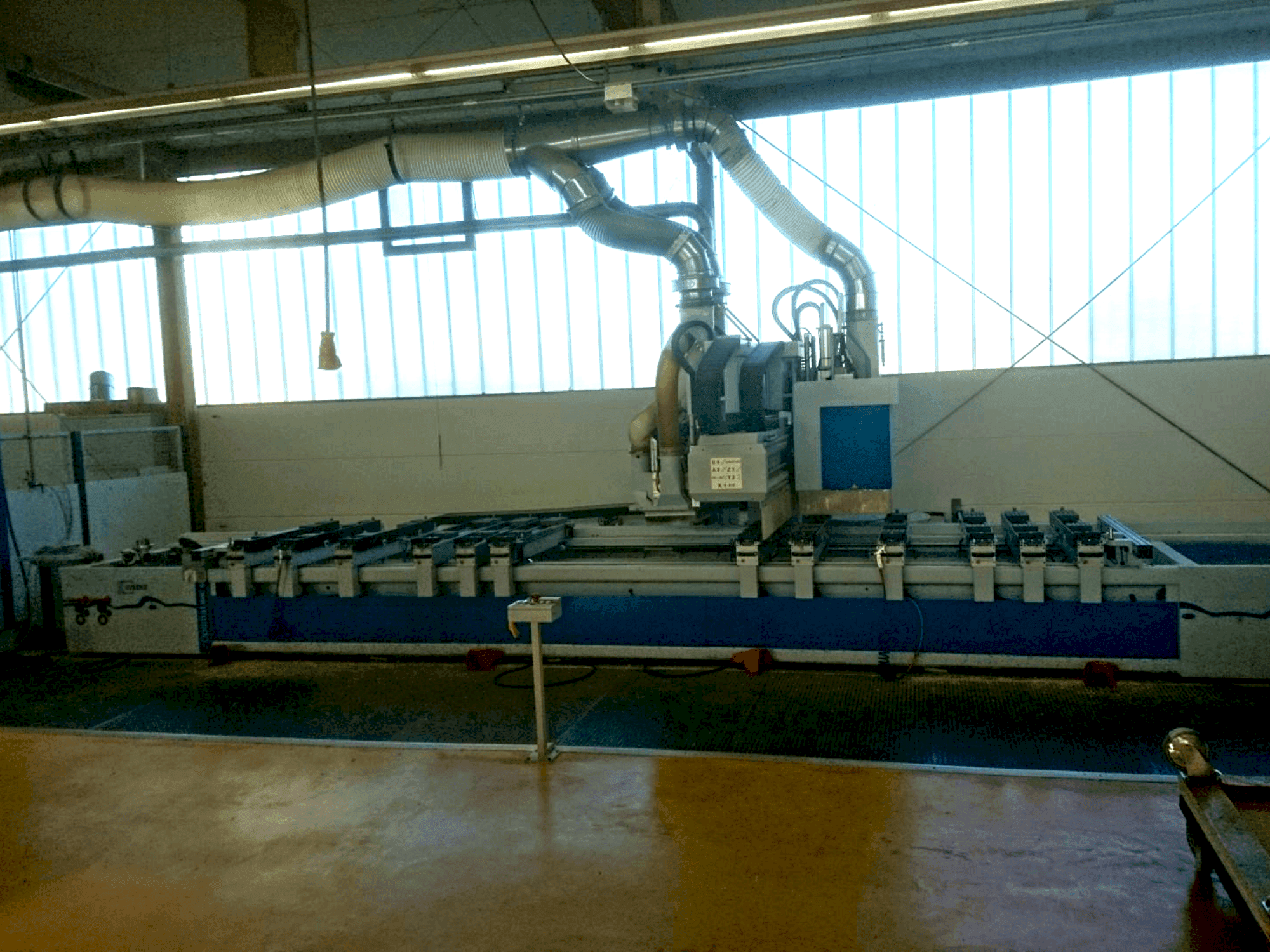

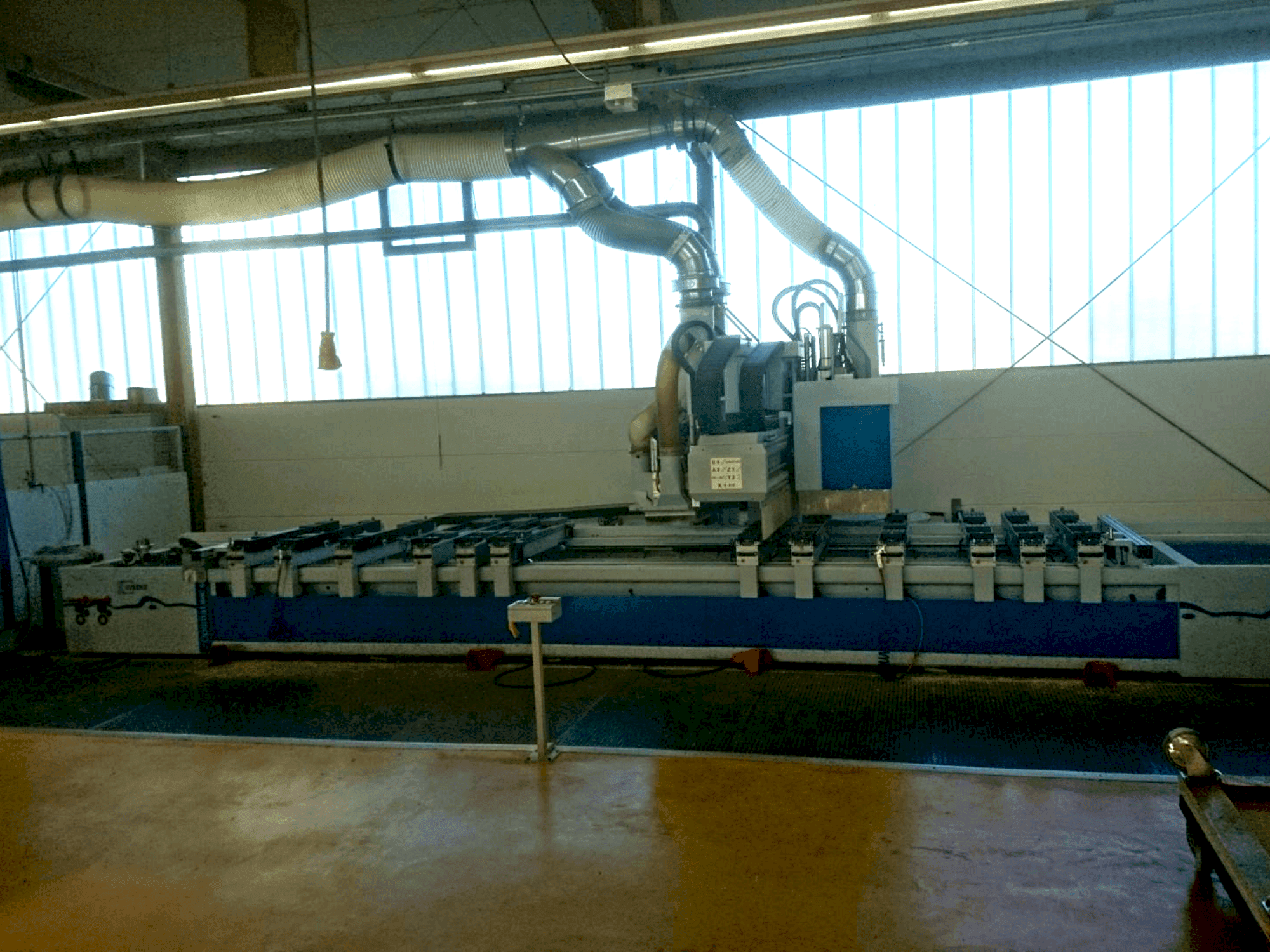

Weeke - Optimat BHC 655DE-WOO-WEE-2004-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para madera

- ➤ Used Weeke Optimat BHC 655 - CNC Processing Center

This woodworking machine was manufactured in 2004. It features a robust CNC processing centre with a compact linear guide system and a ball screw spindle for precise X, Y, and Z axis movement. Equipped with a 9 kW milling spindle, adjustable from 1250-24000 RPM and a 360° positioning axis, it ensures versatile and efficient operations. The machine includes a 100 m³/h vacuum pump and an 18-fold tool holder. For more information about this woodworking machine, please reach out to us.

Resumen

- marca: Weeke

- año: 2004

- MODELO: Optimat BHC 655

- tipo de aplicación: Mecanizado CNC

- Ubicación: Alemania

- tipo de máquina: Router CNC

Información técnica - Weeke Optimat BHC 655

Especificación Técnica

- Velocidad del husillo: 24000 RPM

Información adicional

Additional equipment

- BASIS-table with 6 traverses

- Vacuum pumps (2x 100 m3/h)

- Multiple stop systems

- 18-fold tool holder

- LED positioning system

- side stop cylinder, pneumatically lowerable

- longitudinal stop cylinder, pneumatically lowerable

- Double centre stop lockable with 4 cylinders

- Separate vacuum clamping system (4 vacuum fields in X direction)

- Separate vacuum clamping system for the use of at least 8 workpiece supports with four-fold assignment

Machine Benefits

Technical Machine Benefits

- Axis movement (x-/y-/z-direction): via a compact linear guide system, dust-protected

- Ball screw spindle (y- and z-direction)

- Rack and pinion drive (x direction)

- 4 program-controlled workpiece stops, mounted as a rear row of stops

- 6 program-controlled workpiece stops, mounted as a front row of stops

- 2 side stops mounted on an aluminium profile in y-direction, which can be switched off manually when oversized workpieces are being processed. The side stops can be adjusted manually in y-direction.

- 6 workpiece lifting arms for heavy workpieces

- Milling spindle hsk 9 kw (s6 50%), liquid circulation cooling

- 360 degree positioning axis

Extra Information

Machine still under power

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos