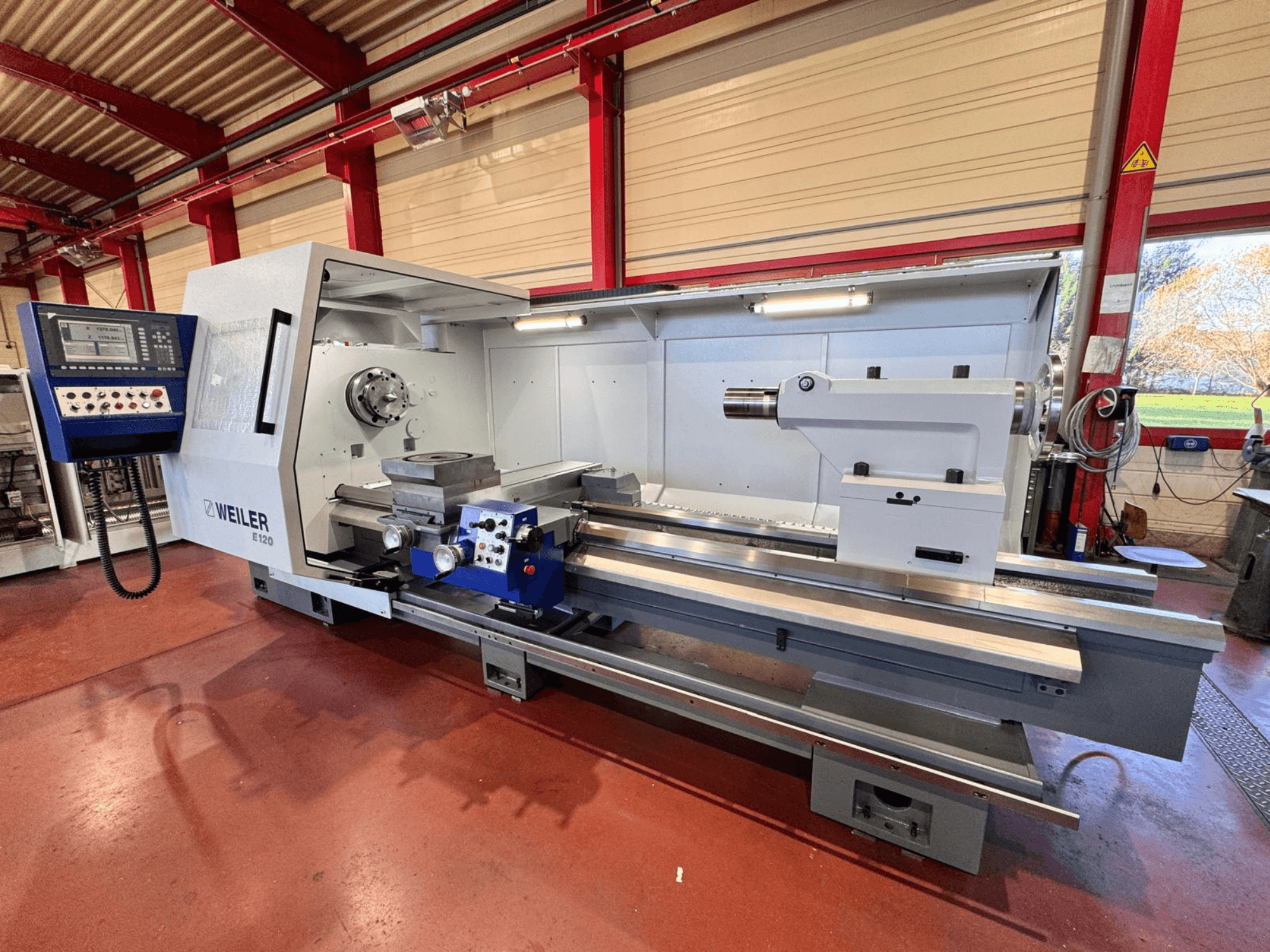

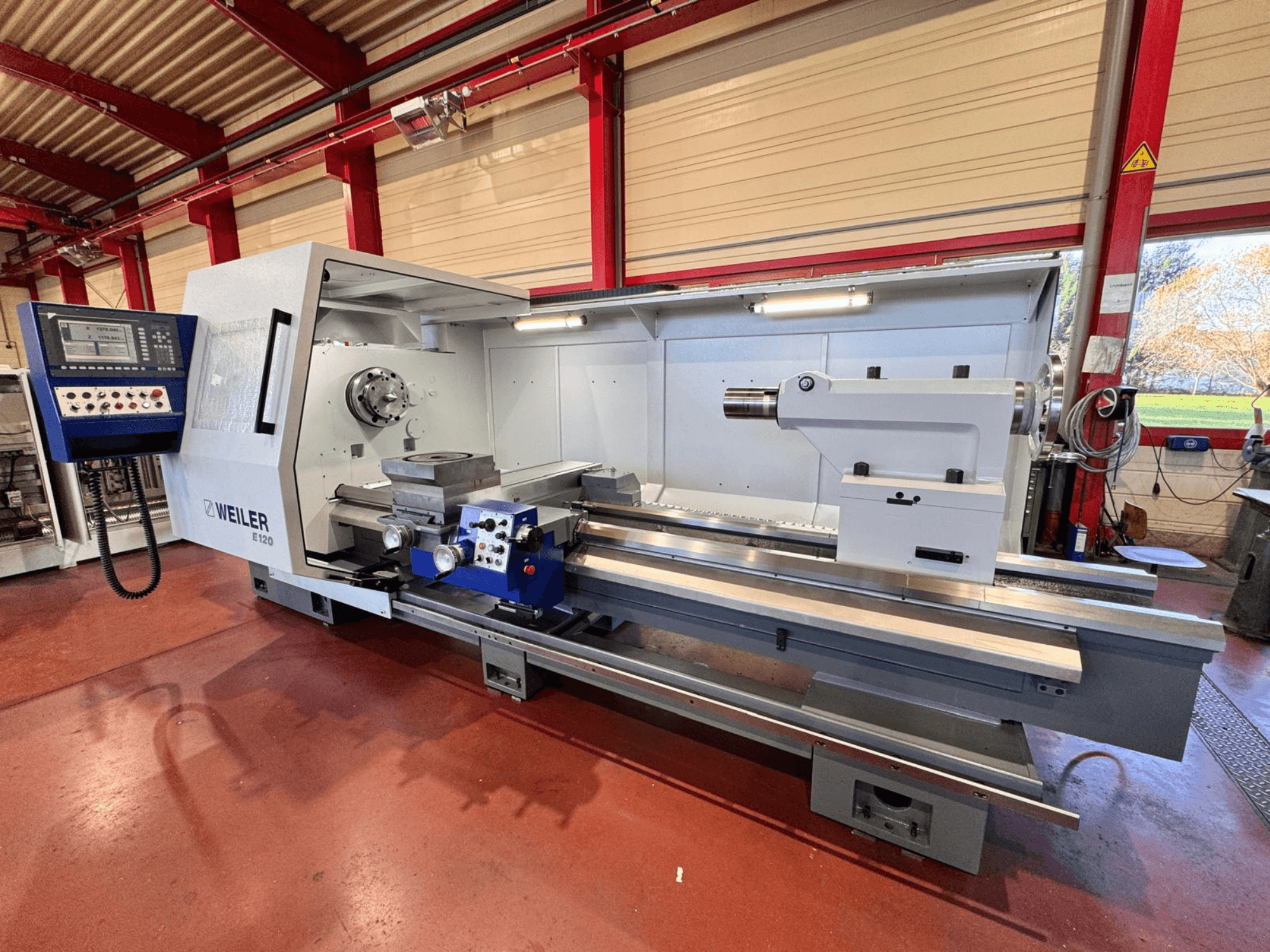

Weiler - E120x3000DE-TUR-WEI-2001-00002

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Venta de Weiler E120x3000 usados | gindumac.com

Esta Weiler E120x3000 fue fabricada en 2001. Tiene una distancia entre ejes de 3000 mm, una altura entre ejes de 600 mm y un diámetro de giro sobre bancada de 1200 mm. El diámetro del husillo es de 165 mm, y ofrece un robusto accionamiento principal con una potencia de 45/37 kW. Ideal para torneado pesado, esta máquina incluye accesorios como un plato de torno, una placa frontal y una luneta. Póngase en contacto con nosotros para obtener más información sobre esta máquina.

Resumen

- marca: Weiler

- año: 2001

- MODELO: E120x3000

- tipo de aplicación: Torneado

- Ubicación: Alemania

- tipo de máquina: Tornos horizontales

- Marca de unidad de control: SIEMENS

Información técnica - Weiler E120x3000

Unidad de Control

- Marca del control: SIEMENS

- Modelo del control: 810 D

Dimensiones

- Altura de la máquina: 2120 mm

- Longitud de la máquina: 5400 mm

- Peso de la máquina: 11500 kg

Recorrido

- Número de ejes: 2

Especificación Técnica

- Potencia del husillo: 45 kW

Información adicional

Área de trabajo:

Distancia entre ejes: 3000 mm

Altura central: 600 mm

Diámetro de giro sobre la cama 1200 mm

Diámetro de giro sobre carro transversal 830 mm

Recorrido del carro transversal: 590 mm

Longitud de la guía del carro transversal: 860 mm

Sección transversal de la herramienta de torneado (Al x An): 40 x 40 mm

Portaherramientas: Parat tamaño 4

Husillo de torneado:

Cabezal de husillo DIN 55027 / 55026, tamaño 15

Diámetro del husillo: 165 mm

Cono del husillo principal: métrico 171

Accionamiento principal:

Potencia de accionamiento (60% / 100% ED) 45 / 37 kW

Par máx. del husillo: 8000 Nm

Rango de velocidad etapa 1: 1-280 rpm

Velocidad de engranaje 2: 4-900 rpm

Contrapunto:

Diámetro de la caña: 140 mm

Carrera de la caña: 300 mm

Conicidad interna de la caña: MK 6

Dimensiones y peso de la máquina:

Longitud total: 5400 mm (sin transportador de virutas), 6535 mm (con transportador de virutas)

Anchura total: 2600 mm

Altura total: 2120 mm

Peso de la máquina: 11.500 kg

Servicios de revisión:

Endurecimiento y rectificado de todas las guías de bancada

Rectificado de las guías del contrapunto

Revisión de todo el conjunto de bancada y carro transversal (rectificado/raspado de todas las guías)

Renovación del revestimiento deslizante del carro de bancada

Renovación o revestimiento de los chaveteros y guías inferiores

Renovación de todos los rascadores

Sustitución de todas las correas

Revisión del conjunto del husillo principal en el cabezal

Renovación del eje X incluyendo rodamientos

Renovación del eje Z incluyendo rodamientos

Revisión de la caña del contrapunto (rectificado del cono MK 6), sustitución del husillo y de la tuerca

Ajuste del sistema de herramientas

Sustitución del motor del husillo principal

Revisión de los motores auxiliares (ejes X y Z)

Revisión de los dispositivos de seguridad existentes (cubierta deslizante/protector de mandíbula)

Sustitución de todos los interruptores giratorios, de palanca y de fin de carrera

Sustitución del codificador del husillo y del volante

Sustitución de los cables móviles y de las mangueras de refrigeración de la zona de trabajo

Sustitución de la unidad de lubricación central

Renovación de las cadenas portacables

Pintura según especificaciones (basalto texturizado estándar y gris claro)

Montaje e inspección geométrica de la máquina según DIN 8605

Equipamiento adicional

1x plato de torno usado Ø630 mm con varias mordazas

1x plato frontal usado Ø1100

1x luneta usada, max. Ø300

1x transportador de virutas usado

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos