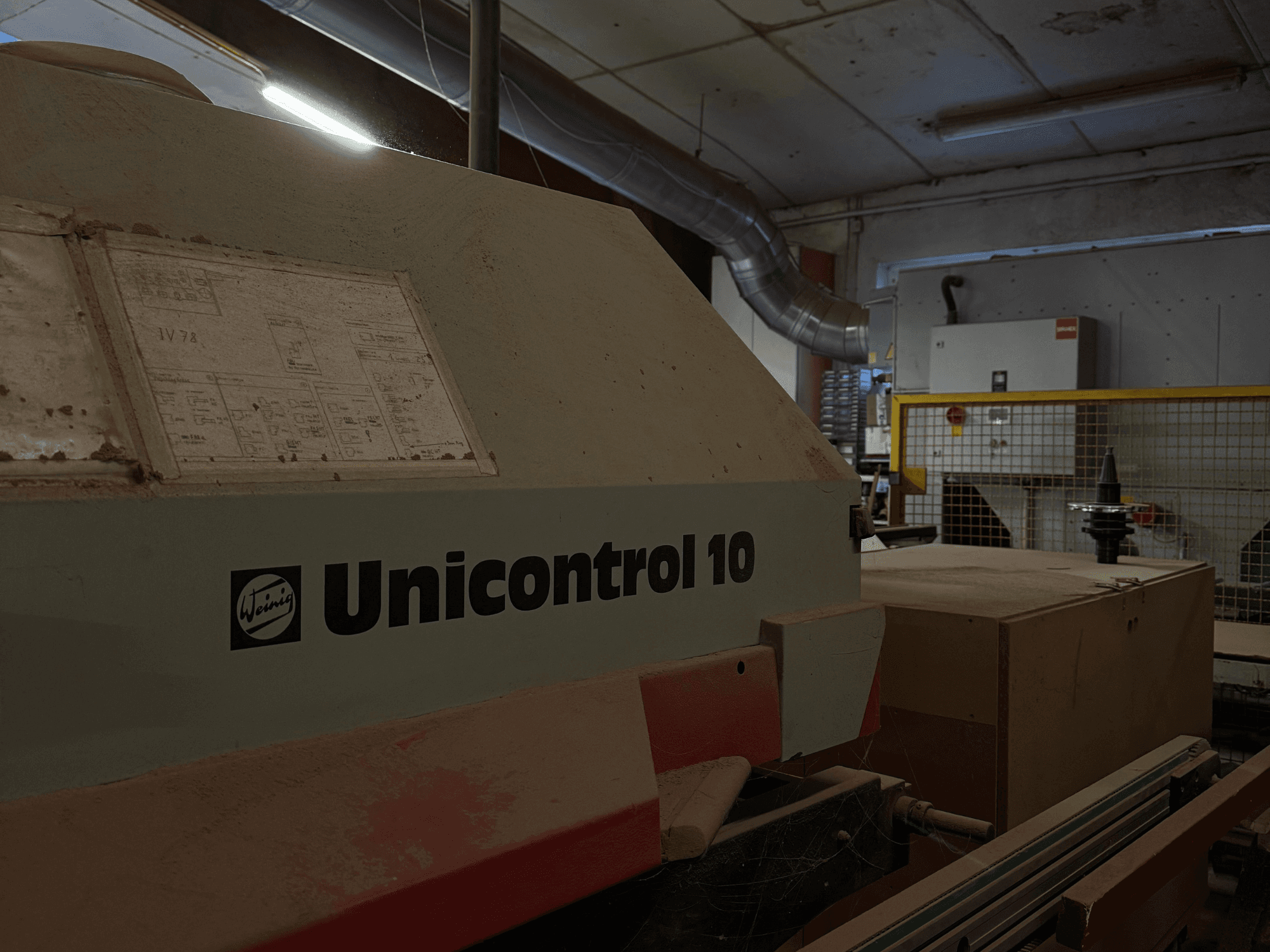

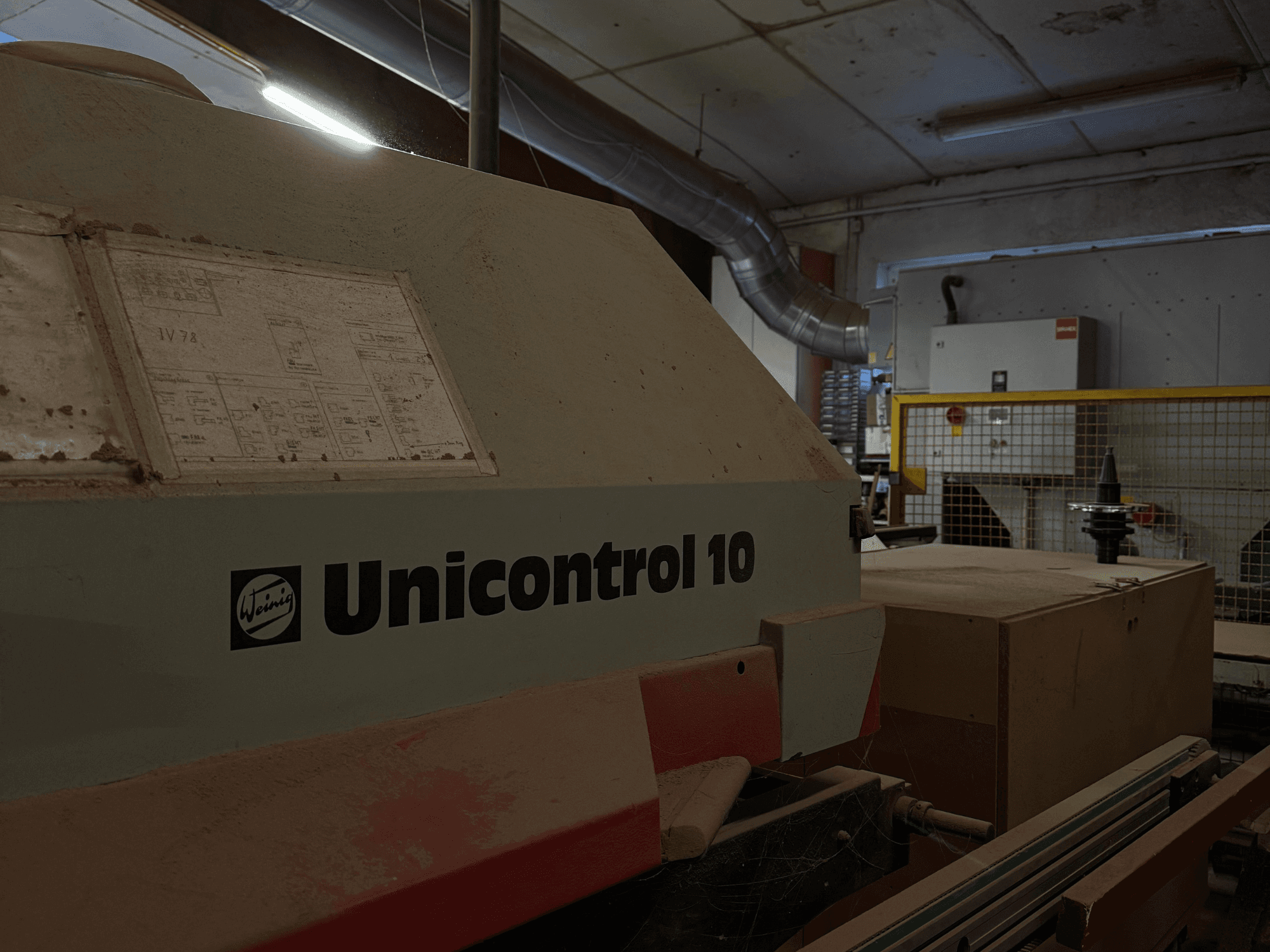

WEINIG / DIMTER - Weinig Unicontrol 10-5DE-MIL-WEI-1998-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para madera

- ➤ Used WEINIG / DIMTER Weinig Unicontrol 10-5 | Wood Mill

This Weinig Unicontrol 10-5 was manufactured in 1998. A robust used window manufacturing machine, it features a working width of 40-220 mm and motor powers up to 15 kW for various machining units. It includes advanced features like a synchronization device, electronic height adjustment, and an automatic turning system for efficient one-man operation. If you are looking to get high-quality milling capabilities, consider the Weinig Unicontrol 10-5 machine we have for sale. Contact us for more information.

Resumen

- marca: WEINIG / DIMTER

- año: 1998

- MODELO: Weinig Unicontrol 10-5

- tipo de aplicación: Fresado (Madera)

- Ubicación: Alemania

- tipo de máquina: Molino de madera

Información técnica - WEINIG / DIMTER Weinig Unicontrol 10-5

Especificación Técnica

- Potencia del husillo: 11 kW

- Velocidad del husillo: 6000 RPM

Información adicional

Capacities

Working width: 40–220 mm

Working height (longitudinal machining): 40–100 mm

Working height (cross machining): 40–100 mm (counter wood height 80 mm)

Workpiece length (longitudinal): min. 220 mm + 2 x tenon length

Workpiece length (cross): min. 275 mm + 1 x tenon length with 320 mm tool diameter

Feed (cross machining)

Motor power: 0.3 kW

Feed speed: 3–25 m/min

Workpiece clamping: 2 clamping claws

Length stop: with scale and reading magnifier for frame or sash outer dimensions

Counter: pneumatically clocked, 4 positions (not for studio windows), up to wood height max. 80 mm

Double part package: single or double part feeding, with cross separation and retention system

1st piece (lying on the stop) wood width: 55–90 mm

2nd piece wood width: 130 mm

Feed (longitudinal machining)

Motor power: 2.2 kW

Feed speed: 4–18 m/min (infinitely variable via frequency converter)

Feed roller spacing: 100/120 mm

Feed roller width: 30/50 mm

Feed roller diameter: 95 mm

Machining units

Crosscut saw

Motor power: 3 kW

Spindle diameter: 40 mm

Spindle speed: 2800 rpm

Tool swing: max. 400 mm

Axial adjustment: pneumatic against 4-fold turret

1st spindle with tenon and slot

Motor power: 11 kW

Spindle diameter: 50 mm

Spindle speed: 3250 rpm

Tool swing: max. 320 mm

Tool clamping length: 320 mm

Axial adjustment range: 240 mm

Number of tools: 4 x 80 mm

Axial adjustment: hydraulic

1st profiling spindle

Motor power: 11 kW

Spindle diameter: 50 mm

Spindle speed: 6000 rpm

Tool diameter: max. 232 mm

Tool zero swing circle: 130–140 mm

Tool clamping length: 320 mm

Axial/radial adjustment range: 240/80 mm

Number of tool positions: 4 x 80 mm

Axial adjustment: hydraulic

2nd profiling spindle

Motor power: 11 kW

Spindle diameter: 50 mm

Spindle speed: 6000 rpm

Tool diameter: max. 232 mm

Tool zero circle: 130–140 mm

Tool clamping length: 320 mm

Axial/radial adjustment range: 240/80 mm

Number of tool positions: 4 x 80 mm

Axial adjustment: hydraulic

Mechanical spindle brakes

For profiling spindle(s)

For crosscut saw and profiling/sawing units

Profile milling unit (horizontal, top; in front of last profiling spindle)

Radially indexed: 2 positions

Axially indexed: 2 positions

Motor power: 3 kW

Spindle diameter: 40 mm

Spindle speed: 5850 rpm

Tool swing: 130 mm

Tool clamping length: 40 mm

Axial adjustment range: 52 mm

Radial adjustment range: 125 mm

Profile milling unit (vertical, right; at end of machine)

Radially indexed: 2 positions

Axially indexed: 2 positions

Motor power: 3 kW

Spindle diameter: 40 mm

Spindle speed: 5850 rpm

Tool swing: 210 mm

Tool clamping length: 160 mm

Axial adjustment range: 90 mm

Radial adjustment range: 100 mm

Length tenoning and slotting spindle (640 mm tool clamping length, instead of 320 mm spindle)

Motor power: 15 kW

Spindle speed: 2925 rpm

Number of tool positions: 8 x 80 mm

Axial adjustment range: 560 mm

Additional equipment

Laser guide light for crosscut saw for section detection

Studio window device

Swiveling length stop +/- 60° with electronic digital display and pneumatic clamping

Sliding counter bar

Special pressure for slanted part production

Restriction: wood thickness max. 120 mm

At -60°: workpiece width max. 110 mm with 80 mm tenon length, or max. 150 mm with counter profiles

Milling package

Synchronization device with automatic immersion (on 1st profiling spindle)

Support rail with sliding belt

High/low clocked feed roller up to the 2nd profiling spindle to shorten the milling path

Software extension with 100 freely programmable milling types

Two axially clocked feed rollers opposite both profiling spindles for production of narrow, short parts

Rung guide

Automatically clocked guide bar in the stop for rung production

Rung support bar from above in the area of the vertical-right profile milling unit at the end of the machine

Electronic height adjustment for feed with electronic digital display

Automatic turning system for one-man operation, including conveyor be

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos