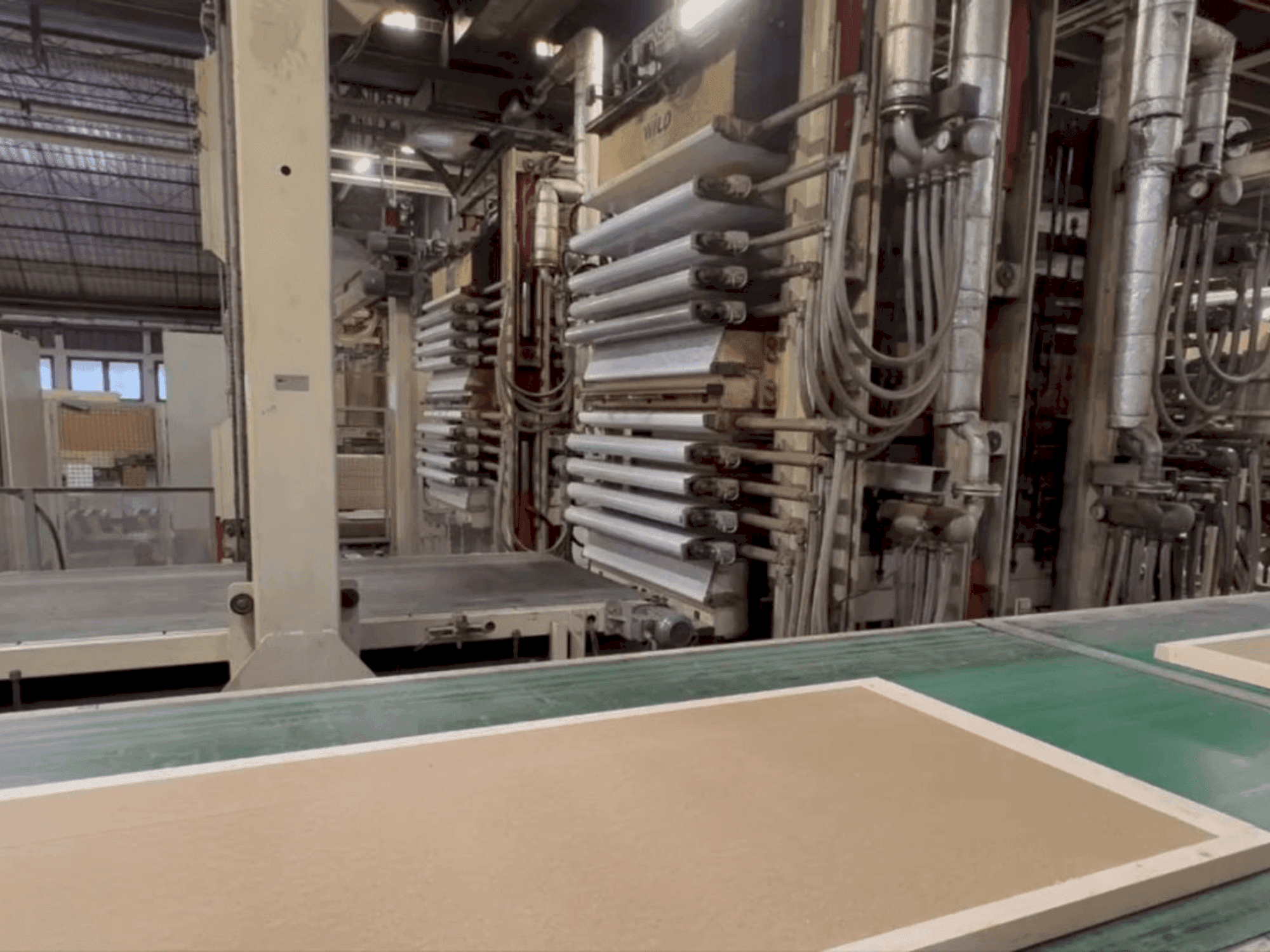

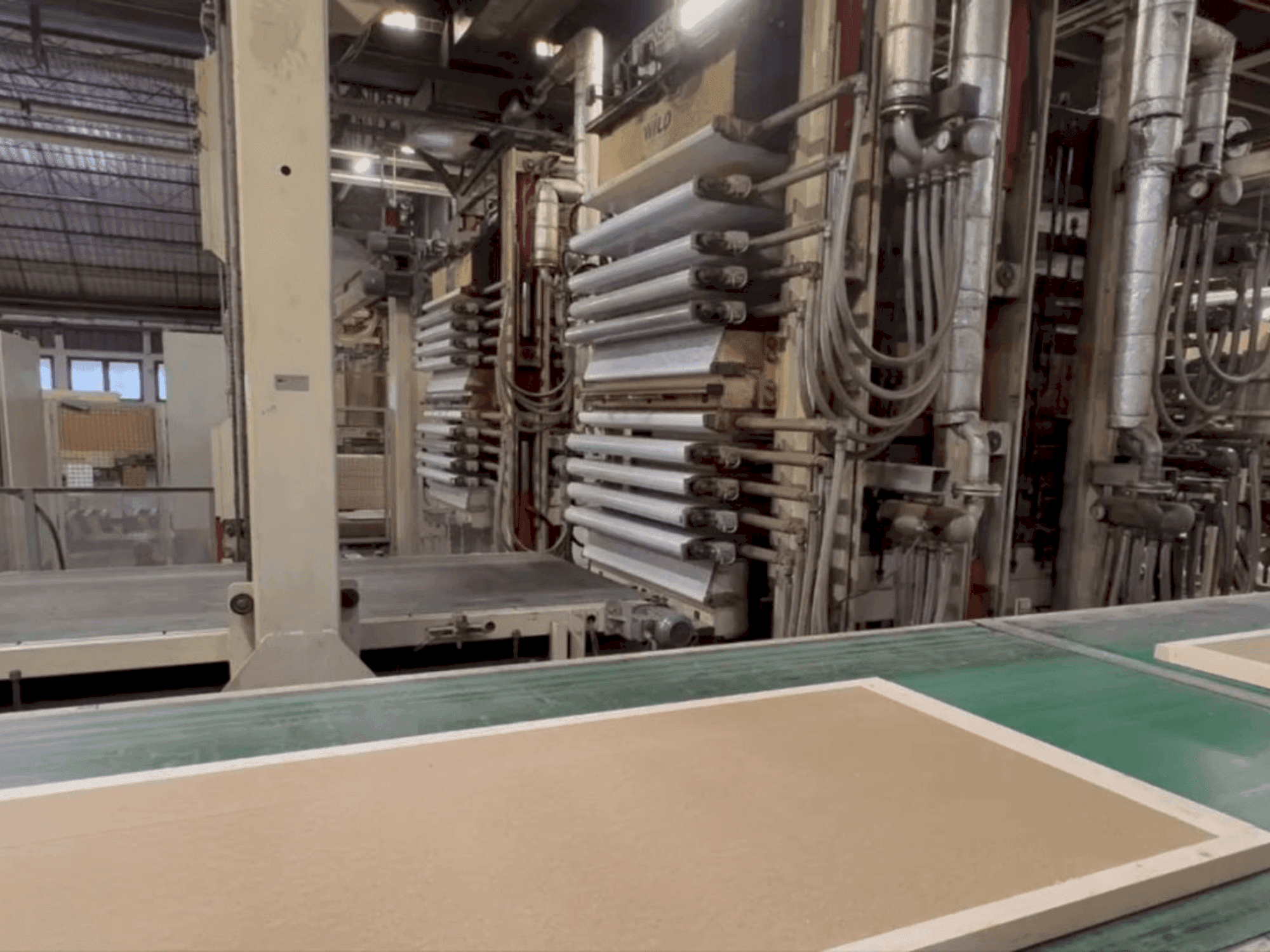

WILD - Door leaf press linePT-COM-WIL-1998-00001

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas para madera

- ➤ Se vende línea completa de producción de madera usada WILD

Esta línea completa de producción de madera WILD se fabricó en 1998. Está diseñada para la producción de puertas, con dimensiones de 1.800 a 2.300 mm de longitud, 500 a 1.300 mm de anchura y espesores de 35, 40 y 44 mm. La línea incluye zonas de encolado, prensado y manipulación de paneles de puerta con avanzados sistemas de alimentación y transferencia. Si desea obtener capacidades de producción de puertas de alta calidad, considere la línea completa de producción de madera WILD que tenemos a la venta. Contáctenos para más información.

Resumen

- marca: WILD

- año: 1998

- MODELO: Door leaf press line

- tipo de aplicación: Prensado / Laminado

- Ubicación: Portugal

- tipo de máquina: Prensa de laminado

- Disponible desde: 01/06/2026

Información adicional

Beneficios de la máquina

Ventajas técnicas de la máquina

- Dimensiones para la fabricación de puertas: longitudes: 1800 - 2300 mm

- Dimensiones para la fabricación de puertas: anchuras: 500 - 1300 mm

- Dimensiones para la fabricación de puertas: espesores 35 / 40 / 44 mm

Más información

Consta de las siguientes áreas: Encolado de paneles de puerta sin fin con estación de colocación de marcos Línea de prensado con estación de carga de tableros de fibra dura Primera área compuesta por: Alimentación de pórticos Transferencia angular con sierra de corte longitudinal y transversal Alimentación y suministro de piezas de marco longitudinales y transversales desde almacenes Estación de corte transversal longitudinal para las piezas del marco longitudinal Estación de conexión para las piezas del marco con el núcleo de la hoja de la puerta, equipada con dispositivos de sujeción Transferencia angular de la cinta transportadora con lanzadera de los núcleos de las hojas de la puerta a los paneles de cartón duro encolados La segunda área consta de: Alimentación de los paneles de tablero duro Máquina de limpieza con cepillos Máquina de aplicación de endurecedor desde abajo Máquina de aplicación de cola desde abajo Transportador de rodillos de disco Transferencia angular para el tablero de fibras duras inferior Dispositivo de giro por vacío para el tablero de fibras duras superior Estación de carga automática para tableros duros y núcleos de hojas de puerta Dos prensas de puertas con dos x cuatro estaciones de prensado cada una, dispuestas paralelamente entre sí Ambas prensas se cargan en la entrada con una cesta de carga de lanzadera Ambas prensas se descargan en la salida con una cesta de descarga de lanzadera Transferencia angular a la entrada en un pulmón de erizo Transferencia angular a la salida del pulmón de erizo y alimentación para apilado Desapilado por vacío unilateral con colocación de placas protectoras Nota: Los datos técnicos y las descripciones se han transcrito a partir de la confirmación original del pedido. La información es sólo de referencia y no es jurídicamente vinculante.

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos