Gracias por su visita

Esta máquina se vendió recientemente. Mire otras opciones similares o contáctenos directamente.

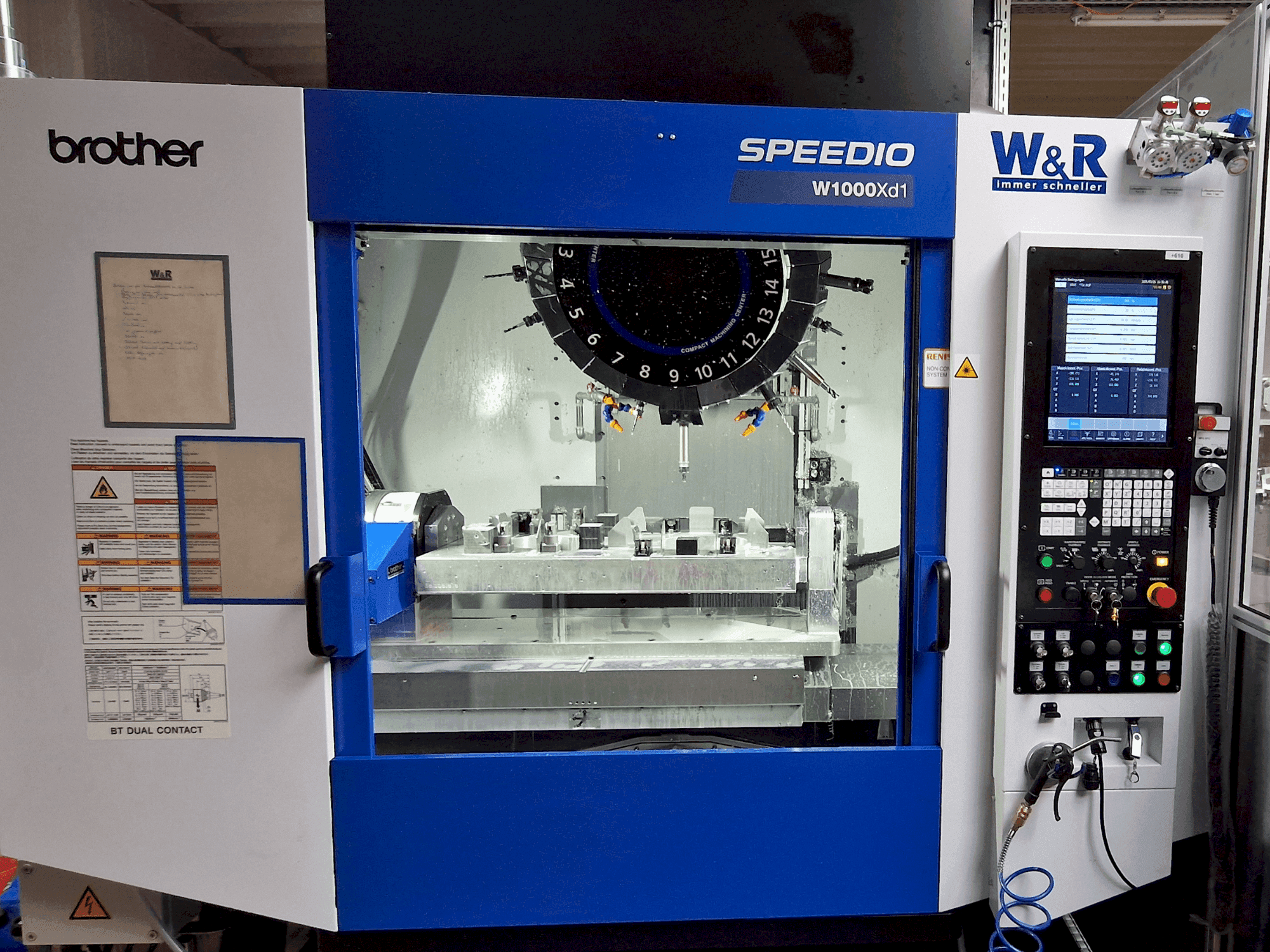

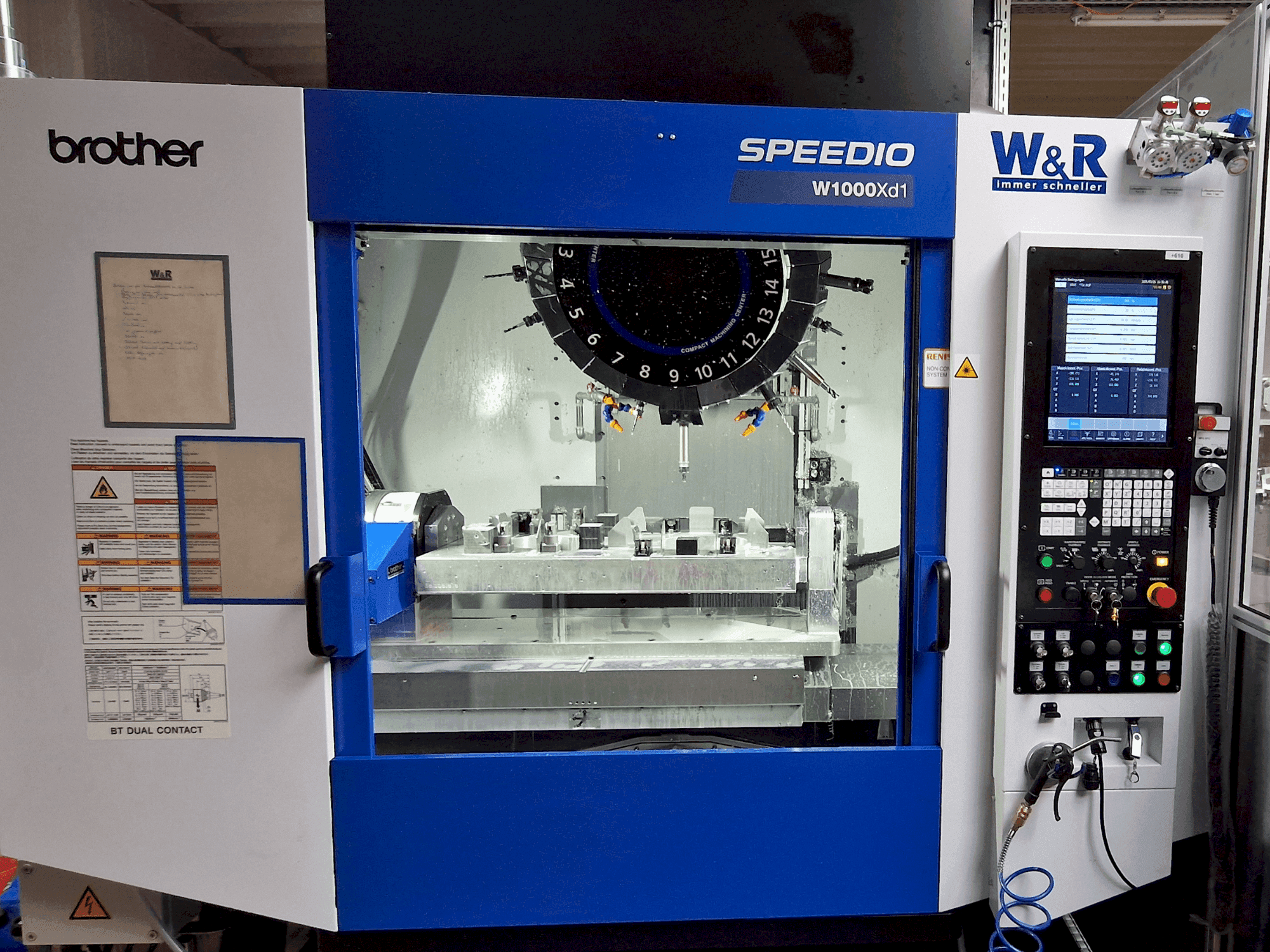

Brother - Speedio W1000Xd1DE-MIL-BRO-2023-00002

¿Tiene más preguntas? ¡Contáctenos!

José María García

+34 601 158 008

j.garcia@gindumac.com

- GINDUMAC

- Productos

- Máquinas herramienta

- ➤ Used Brother Speedio W1000Xd1 For Sale | gindumac.com

This 4-axis Brother Speedio W1000Xd1 was manufactured in 2023. It features a travel range of X-axis: 1000 mm, Y-axis: 500 mm, Z-axis: 480 mm, and a tool magazine with 21 tools. The spindle operates at speeds up to 16,000 rpm. It supports materials like aluminum and steel, and includes a high-pressure coolant system and chip disposal. Consider the opportunity to buy this Brother Speedio W1000Xd1 vertical machining centre. Contact us for more information about this machine.

Resumen

- marca: Brother

- año: 2023

- MODELO: Speedio W1000Xd1

- tipo de aplicación: Fresado

- Ubicación: Alemania

- tipo de máquina: Centro de mecanizado vertical

Información técnica - Brother Speedio W1000Xd1

Recorrido

- Número de ejes: 4

- Recorrido eje X: 1000 mm

- Recorrido eje Y: 500 mm

- Recorrido eje Z: 480 mm

Especificación Técnica

- Velocidad del husillo: 16000 RPM

Información adicional

Additional equipment

- Coolant: Through-spindle, 15 bar, Coolant tank 150 L

- Lubrication: Automatic grease lubrication (X/Y/Z)

- Hydraulic Workpiece Clamping: Pressure: 80–210 bar (mechanically adjustable)

- Pump: 210 bar, 100% ED duty

- Tank: 27 L

- Emulsion Mist Extraction Unit: Suction Capacity: 700 m³/h

- Stages: 5-stage filter with V2A pre-filter

- Includes: PVC hose (2m, Ø200 mm), Flange connection Ø200 mm

Machine Benefits

Technical Machine Benefits

- Integrated chip disposal system: "twin" system with hinged and scraper belt conveyors

- Automatic side doors: pneumatically driven, opens upwards (for auto-loading)

- High-pressure tool cone cleaning

- Tool breakage monitoring: tool Ø > 1. 6 mm; thread former > m2. 0

- Part support control: based on differential pressure (includes sensors and control unit)

- Mounting cone: bbt 30

- Materials supported: aluminum, die-cast aluminum, brass, steel

- Tool magazine: 21 tools

Extra Information

Scope of Delivery Includes: 1x wash box with clipboard 1x Fanuc M710 iC 70 incl. control unit 1x safety fence 1x infeed and outfeed conveyor 1x Automatic side door with drip tray 1x Clamping device 1x chip conveyor 1x Rittal switch cabinet 1x Floor troughs Machine History Fourth Axis CNC Rotary Table: Speed: Max. 100 rpm Clamping Force: 280 Nm Load Capacity: 100 kg (200 kg with counter bearing) Weight: 67 kg Hydraulic Unit: Fully wired with electronic monitoring, temperature sensor, and filters Controls: Via M function, manual switch, or key switch Tool Breakage Monitoring: Via laser, Tool Ø > 1.6 mm Automation System (Side Loading): Robot Cell: Free-standing Plate Chain Conveyor: Size 5000 x 1000 mm, Feed Height ~1100 mm 15 Pallets (362x325 mm) Robot: ABB or FANUC, 6-axis Payload: ~30 kg Radius: ~1700 mm Includes: Controller, quick-change gripper system, robot base

*Pueden existir diferencias entre los datos mostrados y los reales, esto debe ser confirmado por el representante de ventas.

José María García

Opciones de pago

Pago por adelantado

Financiación de activos

Productos relacionados con Brother Speedio W1000Xd1

VMX 60

Hurco - Centro de mecanizado vertical

CMX 70U

DMG MORI - Centro de mecanizado universal

VF 2 SS

HAAS - Centro de mecanizado vertical

EC-400

HAAS - Centro de mecanizado horizontal

A61-5XR

Makino - Centro de mecanizado horizontal

ACE HP 4000

DAEWOO - Centro de mecanizado vertical

V85

MTcut - Centro de mecanizado vertical

MCPH150 UNIPRO 90

HELLER - Centro de mecanizado horizontal

DMC-63V

DECKEL - Centro de mecanizado vertical

DMC 60T

DMG DECKEL MAHO - Centro de mecanizado universal

PICOMAX 55 CNC 2/3

FEHLMANN - Centro de mecanizado vertical

C 800 V

HERMLE - Centro de mecanizado vertical